507710-01Page 4 of 16 Issue 1148

Installation of Line Sets

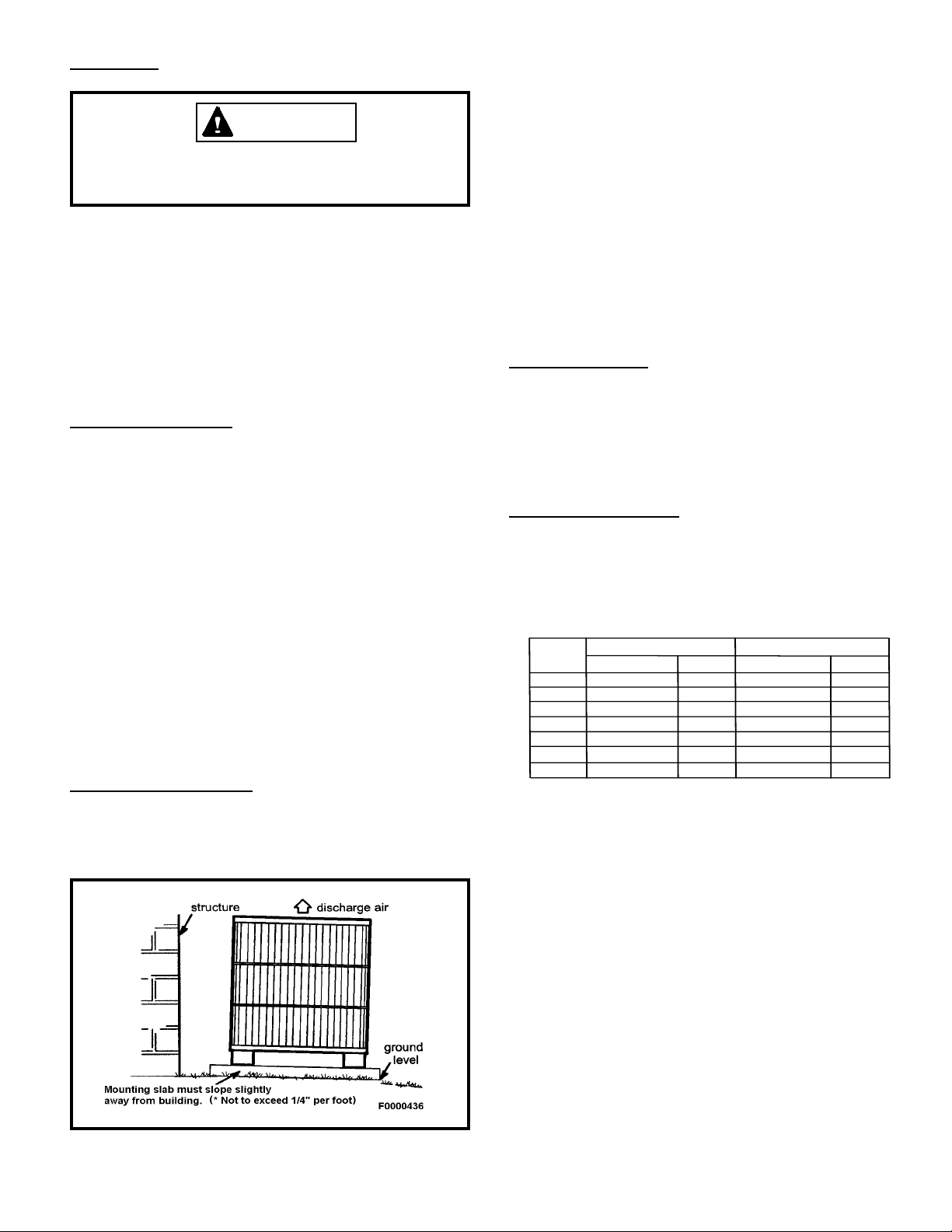

DO NOT fasten liquid or suction lines in direct contact with

the oor or ceiling joist. Use an insulated or suspension type

of hanger. Keep both lines separate, and always insulate

the suction line. Long liquid line runs (30 feet or more) in

an attic will require insulation. Route refrigeration line sets

to minimize length.

DO NOT let refrigerant lines come in direct contact with

foundation. When running refrigerant lines through the

foundation or wall, openings should allow for a sound and

vibration absorbing material to be placed or installed between

tubing and foundation. Any gap between foundation or wall

and refrigerant lines should be lled with a vibration damping

material.

Before making braze connections, be sure all joints are

clean. Before heat is applied for brazing, dry nitrogen should

be owing through the tubing to prevent oxidation and scale

formation on the inside of the tubing.

The following is the recommended method for making braze

connections at the refrigerant line connections:

1. Debur and clean refrigerant tube end with emery cloth

or steel brush.

2. Insert tubing into swage tting connection.

3. Wrap wet rags over valves to protect from heat.

4. Allow dry nitrogen to ow through refrigerant lines.

5. Braze joint, using a suitable brazing alloy for copper to

copper joints.

6. Quench the joint and tubing with water using a wet rag.

Leave rag on tting body and re-wet with water to help

cool area.

Leak Check

Refrigeration lines and indoor coil must be checked for leaks

after brazing and before evacuation. The recommended

procedure is to apply a trace amount of vapor refrigerant

(approximately two ounces or 3 psig) into the line set and

indoor coil, then pressurize with 150 psig of dry nitrogen.

Use a refrigerant leak detector to check all joints. The

system may also be checked for leaks using a halide torch

or pressure and soapy solution. After completion of leak

check, relieve all pressure from system before evacuation.

Evacuating And Charging Instructions

NOTE: Intentional release of CFC or HCFC refrigerant

to the atmosphere violates Federal Law. It may also

violate State and Local Codes. Check all Federal, State

and Local Codes before proceeding.

These outdoor units are pre-charged at the factory with

adequate refrigerant to handle 15 feet of refrigerant tubing.

NOTE: DO NOT use any portion of the charge for purging

or leak testing. It is mandatory that a thorough evacuation

of the refrigeration lines and indoor coil be performed.

The liquid line and suction line service valves have been

closed after nal testing at the factory. DO NOT disturb

these valves until the lines have been leak checked and

evacuated or the charge in the unit may be lost.

1. Connect the vacuum pump to the center hose of the

manifold gauge set, the low-pressure manifold gauge to

the vapor service valve and the high pressure manifold

gauge to the liquid service valve.

NOTE: Unnecessary switching of hoses can be avoided

and complete evacuation of all lines can be achieved by

also connecting a branch hose from the manifold gauge

center port to a cylinder of the proper refrigerant. Provide

a separate shut-off valve to vacuum pump to avoid

contaminating vacuum pump oil with refrigerant.

2. The valves should be kept in the “front seated” (closed)

position. This will allow evacuation of the refrigeration

lines and the indoor coil, without disturbing the factory

charge in the outdoor unit.

3. Follow the vacuum pump manufacturer’s instructions.

Allow the pump to operate until the system has been

evacuated down to 300 microns. Allow the pump to

continue running for an additional 15 minutes. Turn OFF

the pump and leave the connections secured to the two

(2) service valves. After 5 minutes, if the system fails

to hold 500 microns or less, check all connections for

tight t and repeat the evacuation procedure.

4. Isolate the vacuum pump from the system by closing

the shutoff valves on the gauge-set. Disconnect the

vacuum pump.

Opening Service Valves

After evacuation of the connecting lines, remove the service

valve cap and fully insert the hex wrench into the stem. A

back-up wrench is required on the valve body to open the

valve stem. Back-out counterclockwise until the valve stem

just touches the coined edge.

Wrench sizes:

3/8 service valve: 3/16” Hex wrench

3/4 service valve: 5/16” Hex wrench

7/8 service valve: 5/16” Hex wrench

If ANY refrigerant tubing is buried, provide a 6 inch

vertical rise at service valve. Refrigerant tubing lengths

up to 36 inches may be buried without further special

consideration. For lengths above 36 inches, consult your

local distributor.

CAUTION