Chapter Two

2.1 Mechanis Explanation

The 1540/1541 echanis is installed in the syste horizontally,

however the drive will fuction if ounted vertically. The

echanical parts of the drive include an alu inu chassis, a

stepping otor, head positioning asse bly, drive otor, a hub and

spindle asse bly for centering and retaining the edia during

operation. The agnetic head is of a glass cera ic construction.

2.2 Function explanation

The drive is itself an independent e ory device. The drive is

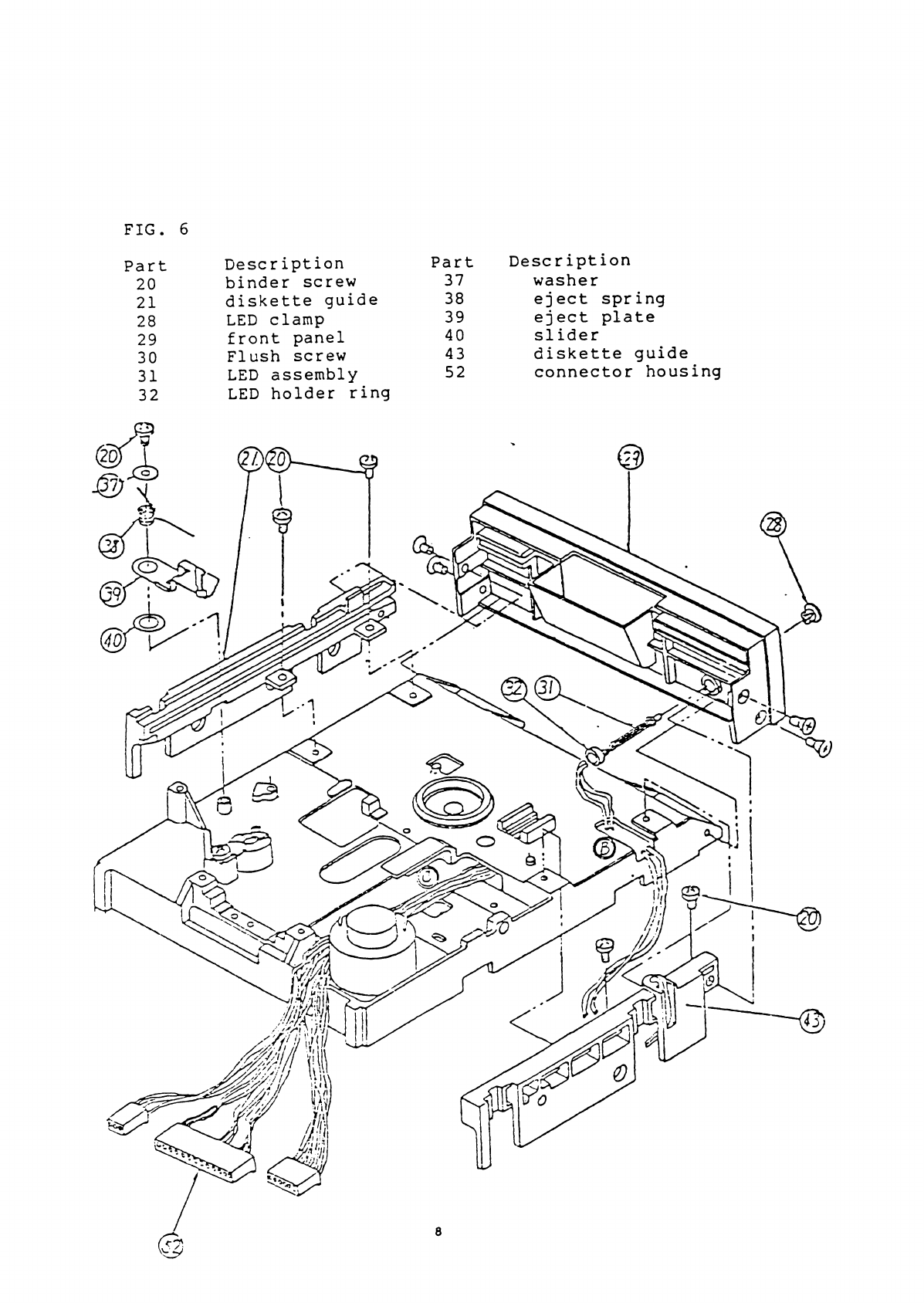

co posed of a edia cla p rotating jnechanis , ahead positioning

echanis and an eject echanis . When the front door opens, the

edia can be inserted. All positioning operation excluding insertion

and re oval of the edia are controlled by the internal guide

echanis . Closing the front door causes the edia cla p echanis

to operate. Two operations are perfor ed in the following order:

a) The edia is centered.

b) The edia is cla ped and retained between the spindle and the

hub.

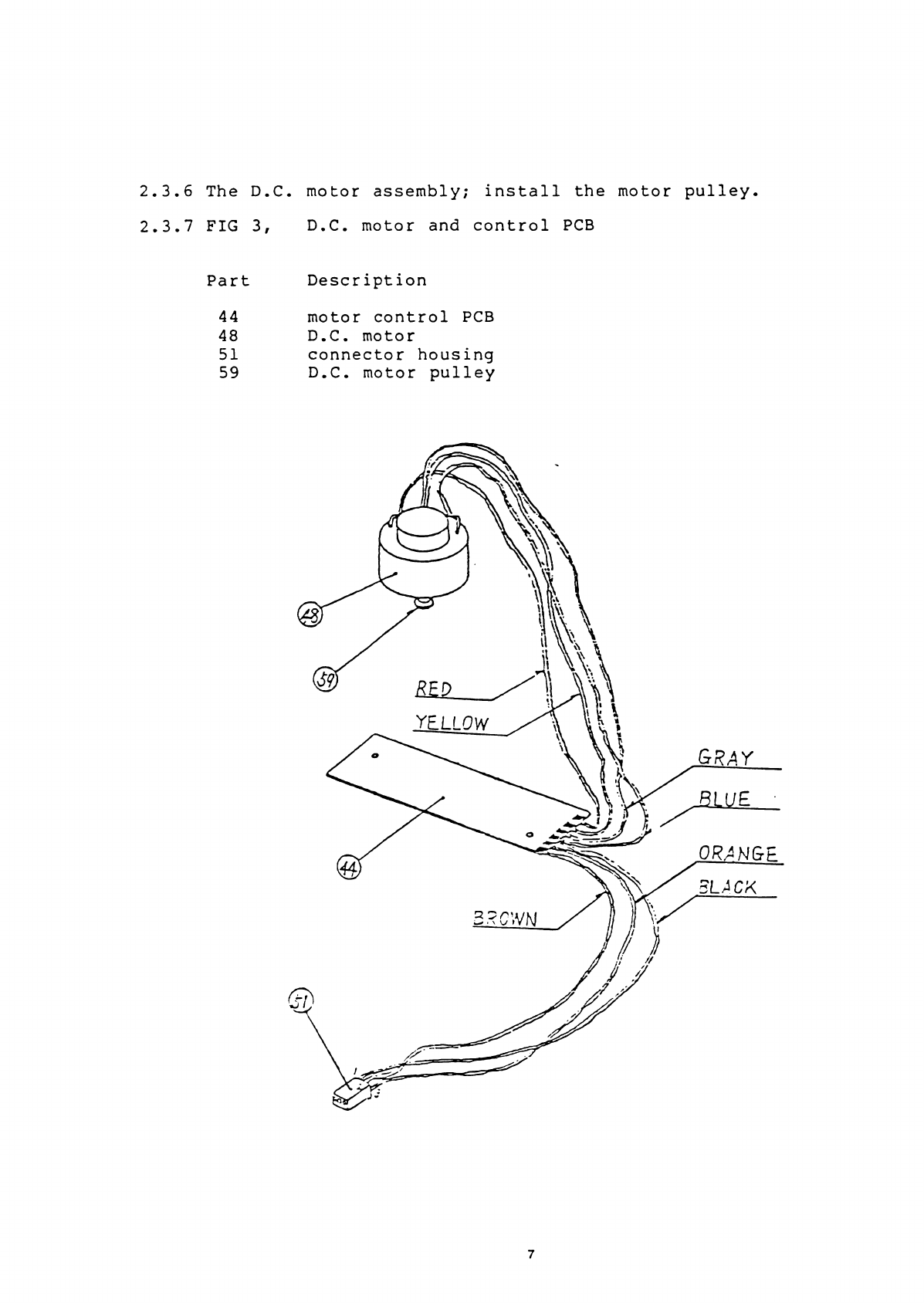

The spindle and hub rotate at 300 r.p. . through a closed-loop

control circuit e ploying a D.C. otor/tacho eter. It is i portant

that the relationship between the head and the edia is aintained

correctly during operation. For this purpose, a pressure pad is

used to hold and press down the edia (about 12g) fro the opposite

side of the head, to aintain the correct contact with the head.

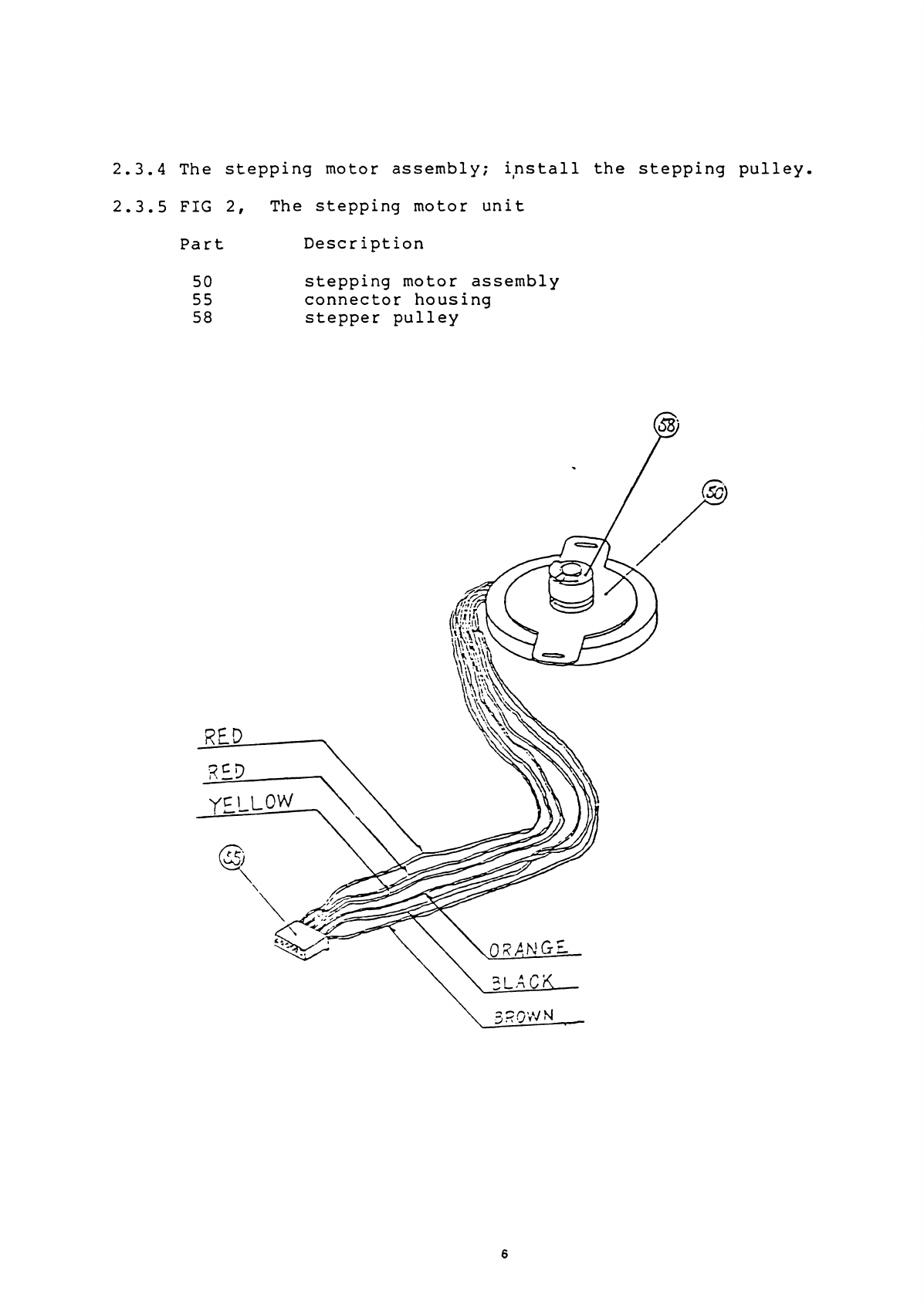

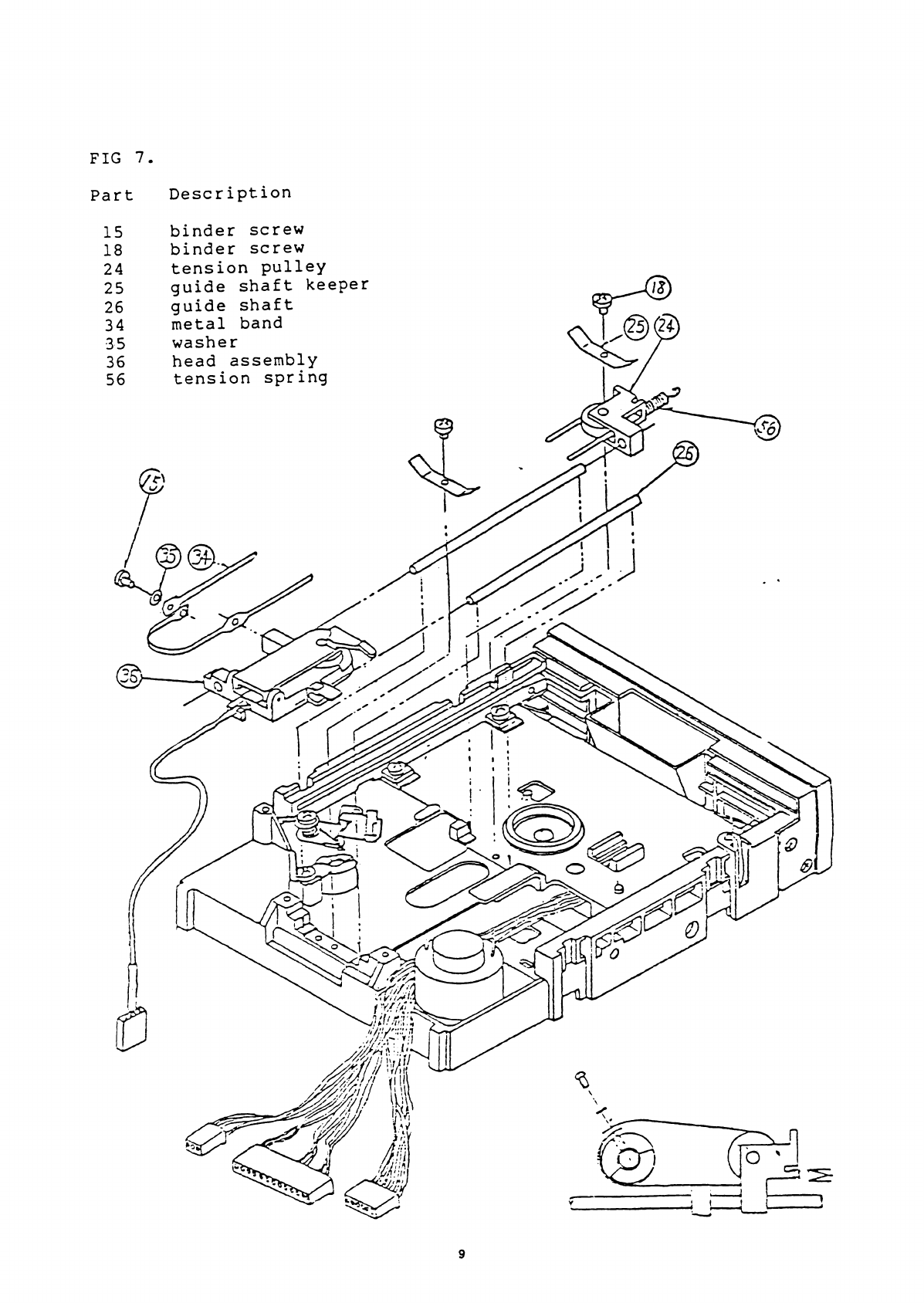

This head asse bly is coupled by a etal band to a four phase

stepping otor the perfor s the track positioning. One step of the

stepping otor corresponds to a 1/2 track ove ent. Use of a high

speed stepping otor and etal band drive, this series of disk

drives can perfor access operations at a very high speed.

2.3 Asse bly procedure

2.3.1 The.housing asse bly; install the eject pin and the spindle.

2.3.2 The housing asse bly; on the reverse side install the spindle

pulley.

4