S&S Northern ODE-3-110023-101 User manual

Optidrive E3 Simple Set-Up Guide

(0.37kW~37kW)

V2.0.0

Optidrive E3 Set-up Guide

Contents

Section

Heading

Page

1

Safety & General Information

1

2

Basic

Technical Data

2

3

Display & Keypad

3

4

Control Terminals

6

Power terminals & Motor Connections

8

6

Basic

EMC

Information

11

7

Getting Started

1

9

8

Parameter P

-

1

2

3

9

Keypad Control

2

9

10

Analogue Inputs

3

4

1

1

Analogue

/Digital

Output

3

1

2

Relay Output

3

6

1

3

Start Mode & Auto Restart

3

7

1

4

Motor Control

3

8

1

DC Injection braking

4

3

1

6

Dynamic Braking

4

7

1

7

Read Only Status Parameters

0

1

8

Fire Mode

4

1

9

Trip Codes

20

IP66 Switched

Units

6

2

Optidrive E3 Set-up Guide P a g e | 1

1

Safety & General Information

Safety Information

Please read and observe the safety information in the Invertek Optidrive E3 Installation and Operating

Instruction User Guide.

This Set-Up Guide does not contain safety information as it is assumed that the customer has read and

understood the safety information in the Optidrive E3 Installation and Operating Instruction User Guide.

General Information

The contents of this Set-Up Guide are believed to be correct at the time of printing. In the interests of

continuous improvement, the authors reserve the right to change the contents of the Set-Up Guide ithout

notice.

All rights reserved. No part of this Set-Up Guide maybe reproduced or transmitted in any form or by any

means, electrical or mechanical, including photocopying, recording or by any information storage or retrieval

system, ithout permission in riting from the publisher.

General information a out this Set Up Guide

This set up guide gives basic information on setting up the Optidrive E3 in terminal and keypad control. It gives

information on ho to change the terminal configuration to suit a particular application requirement.

This set up guide gives information on the operation of various parameters to allo the user to set the drive up

to their particular requirements.

Optidrive E3 Software

This set up guide as ritten ith reference to the latest version of Optidrive E3 soft are – V3.08. Depending

on the age of the drive, some of the features described in this set up guide may not be available.

P a g e | 2 Optidrive E3 Set-up Guide

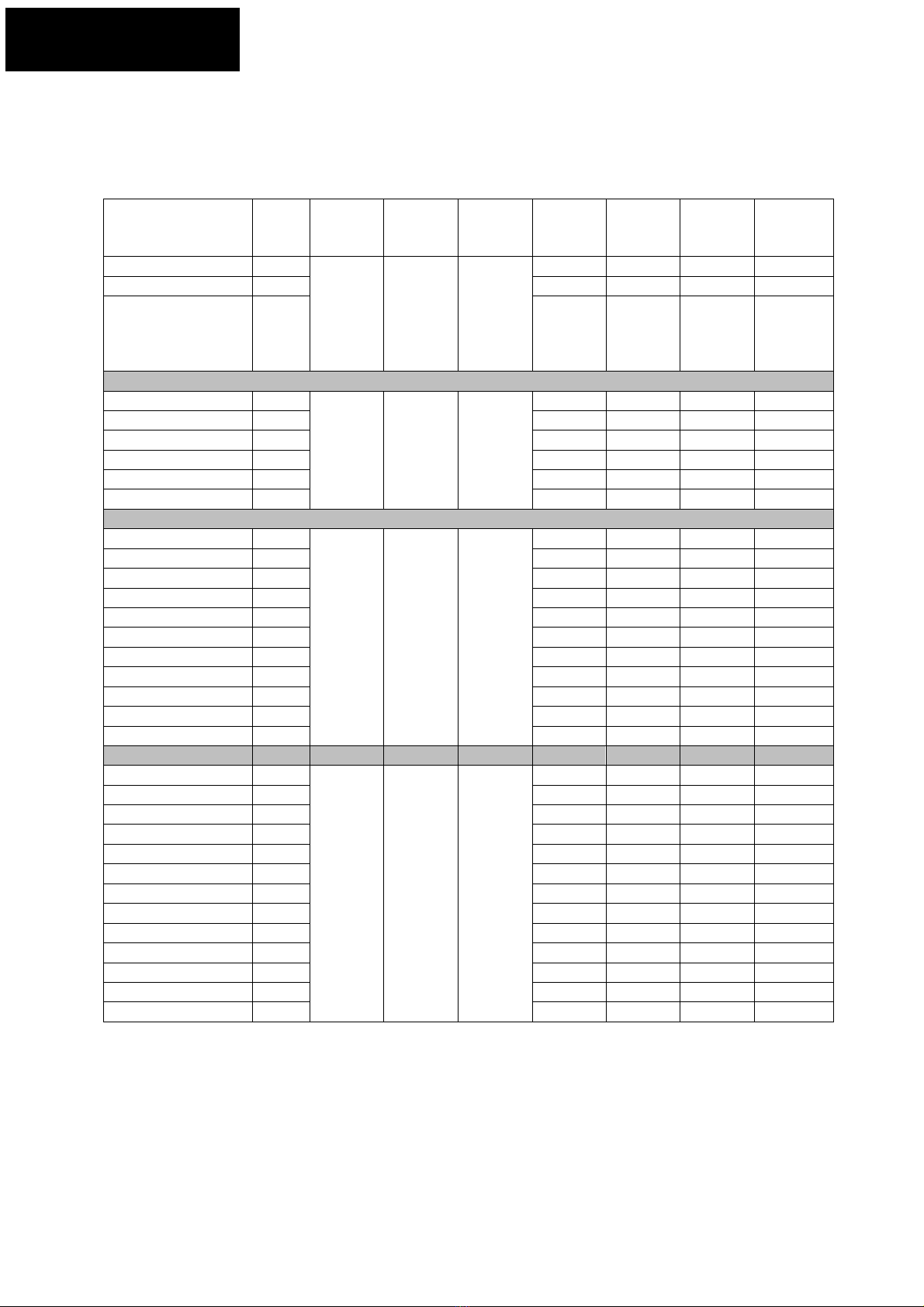

2

Basic Technical Data

E3 Basic Technical Data

All of the E3 drives below are 3 phase output

Model Number Frame

size

Input

voltage

Number

of input

phases

utput

voltage

kW utput

current

Internal

EMC

filter

Internal

braking

transistor

ODE-3-110023-101# 1

110 to

11 VAC

±10%

1

0 to

230V

(2 0V

max)

(Voltage

doubler)

0.37 2.3 No No

ODE-3-110043-101# 1 0.7 4.3 No No

ODE-3-2100 8-104# 2 1.1 .8 No Yes

ODE-3-120023-1F1# 1

200 to

240VAC

±10%

1

0 to

230V

(2 0V

max)

0.37 2.3 Yes No

ODE-3-120043-1F1# 1 0.7 4.3 Yes No

ODE-3-120070-1F1# 1 1. 7 Yes No

ODE-3-220070-1F4# 2 1. 7 Yes Yes

ODE-3-22010 -1F4# 2 2.2 10. Yes Yes

ODE-3-3201 3-1&4# 3 4.0 1 .3 No Yes

ODE-3-120023-301# 1

200 to

240VAC

±10%

3

0 to

230V

(2 0V

max)

0.37 2.3 No No

ODE-3-120043-301# 1 0.7 4.3 No No

ODE-3-120070-301# 1 1. 7 No No

ODE-3-220070-3F4# 2 1. 7 Yes Yes

ODE-3-22010 -3F4# 2 2.2 10. Yes Yes

ODE-3-320018-3F4# 3 4.0 18 Yes Yes

ODE-3-320240-3F4# 3 . 24 Yes Yes

ODE-3-420300-3F4# 4 7. 30 Yes Yes

ODE-3-420460-3F4# 4 11 46 Yes Yes

ODE-3- 20610-3F42 1 61 Yes Yes

ODE-3- 20720-3F42 18. 72 Yes Yes

ODE-3-140022-3F1# 1

380 to

480VAC

±10%

3

0 to

400V

( 00V

max)

0.7 2.2 Yes No

ODE-3-140041-3F1# 1 1. 4.1 Yes No

ODE-3-240041-3F4# 2 1. 4.1 Yes Yes

ODE-3-2400 8-3F4# 2 2.2 .8 Yes Yes

ODE-3-24009 -3F4# 2 4 9. Yes Yes

ODE-3-340140-3F4# 3 . 14 Yes Yes

ODE-3-340180-3F4# 3 7. 18 Yes Yes

ODE-3-340240-3F4# 3 11 24 Yes Yes

ODE-3-440300-3F4# 4 1 30 Yes Yes

ODE-3-440390-3F4# 4 18. 39 Yes Yes

ODE-3-440460-3F4# 4 22 46 Yes Yes

ODE-3- 40610-3F42 30 61 Yes Yes

ODE-3- 40720-3F42 37 72 Yes Yes

For IP20: Replace # with a ‘2’

For IP66 Non-switched: Replace # with a ‘A’

For IP66 switched: Replace # with a ‘B’

ODE-3-3201 3-1&4#: Replace ‘&’ with a ‘0’ for IP20 – no internal EMC filter. Replace ‘&’ with ‘F’ for IP66 –

internal EMC filter fitted

Optidrive E3 Set-up Guide P a g e | 3

3

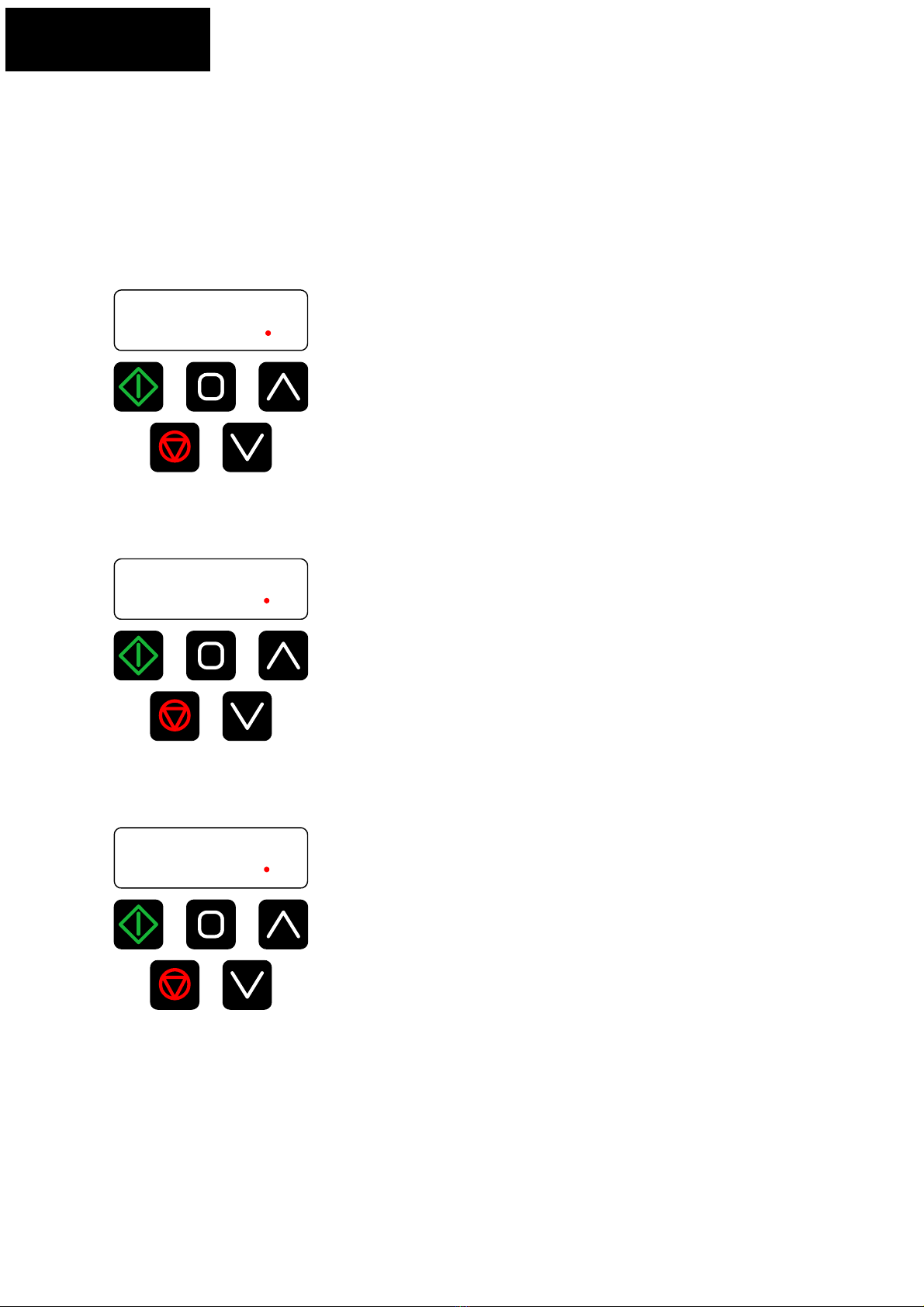

Display & Keypad

Display and Keypad

The Optidrive E3 has a LED display and 5 push buttons that allow the user to monitor the drives operation,

adjust parameter values, reset a drive trip and also ontrol the drive in keypad ontrol (IP66 Outdoor rated

keypad shown)

Resetti

ng to factory default parameters

Changing parameter values

StoP

Press and hold the

NAVIGATE button >2s

to go into the

parameter menu

P-01

Use the UP and

DOWN buttons to

select the required

parameter

P-08

Press and release the

NAVIGATE button to

select parameter edit

mode

10 00

Adjust to tge required

value using the UP

and DOWN buttons

Press and release the

NAVIGATE button to

return to the parameter

menu (parameter

changes are saved when

the NAVIGATE button is

pressed). Use the UP

and DOWN buttons to

select another parameter

to edit

P-08

StoP

Press and hold the

NAVIGATE button >2s

to return to the

operating display

OR

StoP

Press and hold the

UP, DOWN and STOP

buttons for >2s

P-dEF

Display will show

P-dEF

Press the STOP/

RESETbutton to reset

the drive

StoP

All parameters will

now be set to their

factor default settings

4-20F

Press the STOP/

RESET button

StoP

The display will show

StoP

after the fault

has been reset

Resetting a trip

P a g e | 4Optidrive E3 Set-up Guide

3

Display & Keypad

The display an also be used to monitor:

•Output frequen y

•Output speed

•Output urrent

•Output power

From default settings, when the drive is enabled, the display will show output frequen y:

H 500

Press and release the NAVIGATE button, the display will show Output urrent:

A 46

Press and release the NAVIGATE button, the display will show Output power:

P 72

Optidrive E3 Set-up Guide P a g e | 5

3

Display & Keypad

The display an also show motor RPM.

To show RPM on the display, set the motor rated speed into parameter P-10:

1500

When the NAVIGATE button is pressed, the display will y le from:

•Output frequen y

•Output RPM

•Output Current

•Output Power

•Output frequen y………..

NOT : On high inertia loads (fans/flywheels et .), if the display is required to show RPM, set parameter P-10 to

the syn hronous speed of the motor:

2 pole – 3000

4 pole – 1500

6 pole – 1000

8 pole – 750

P a g e | 6Optidrive E3 Set-up Guide

4

Control Terminals

Control Terminal Specification

All digital inputs are positive logic i.e. they must be connected to 24VDC to make them active.

Terminal Signal Description

+24VDC User Output +24VDC, 00mA maximum

2 Digital input Logic : Input voltage range: 8V to 30VDC

Logic 0: Input voltage range: 0V to 4VDC

3 Digital input 2

4 Digital input 3 /

Analogue input 2

When used as a digital input – as above

When used as an analogue input: 0V to + 0V, 0 to 20mA, 4 to 20mA

5 + 0VDC User output + 0VDC, 0mA maximum ( kΩ minimum pot resistance)

6 Analogue input /

Digital input 4

When used as an analogue input: 0V to + 0V, 0 to 20mA, 4 to 20mA

When used as a digital input – as above

7 0V 0V common, internally connected to terminal 9

8 Analogue output /

Digital output

Analogue output: 0 to 0V, 20mA maximum

Digital output: 0 to 24VDC, 20mA maximum

9 0V 0V common, internally connected to terminal 7

0 Status relay common Contact:

250VAC, 6A

30VDC, 5A

Status relay normally open

contact

Control terminal connection diagram – factory default functionality

Optidrive E3 Set-up Guide P a g e | 7

4

Control Terminals

Control terminals – Factory default functionality

Terminal 1

+24VDC User supply ( 00mA maximum)

Terminal 2: Stop / un (Enable)

Switch Open: Drive stopped

Switch Closed: Drive running / enabled

Terminal 3: Forward / everse

Switch Open: Motor running in forward direction of rotation

Switch Closed: Motor running in reverse direction of motor rotation

Terminal 4: Analogue speed reference / Preset speed 1

Switch Open: Motor speed controlled by analogue input (potentiometer input)

Switch Closed: Motor speed controlled by setting of preset speed (parameter P-20)

Terminal 5: +10V eference power supply

Speed potentiometer + 0V reference

Terminal 6: Analogue input 1

Speed potentiometer wiper: 0 to + 0V

Terminal 7: 0V

Speed potentiometer 0V reference

(internally connected to Terminal 9)

Terminal 8: Analogue output – motor speed

0 to + 0VDC output proportional to motor speed

(0 to 50Hz = 0 to + 0V) (20mA maximum)

Terminal 9: 0V

0V reference

(internally connected to Terminal 7)

Terminals 10 & 11: Drive healthy relay (NO - Normally Open)

Relay Open: Drive fault

Relay closed: Drive healthy

P a g e | 8Optidrive E3 Set-up Guide

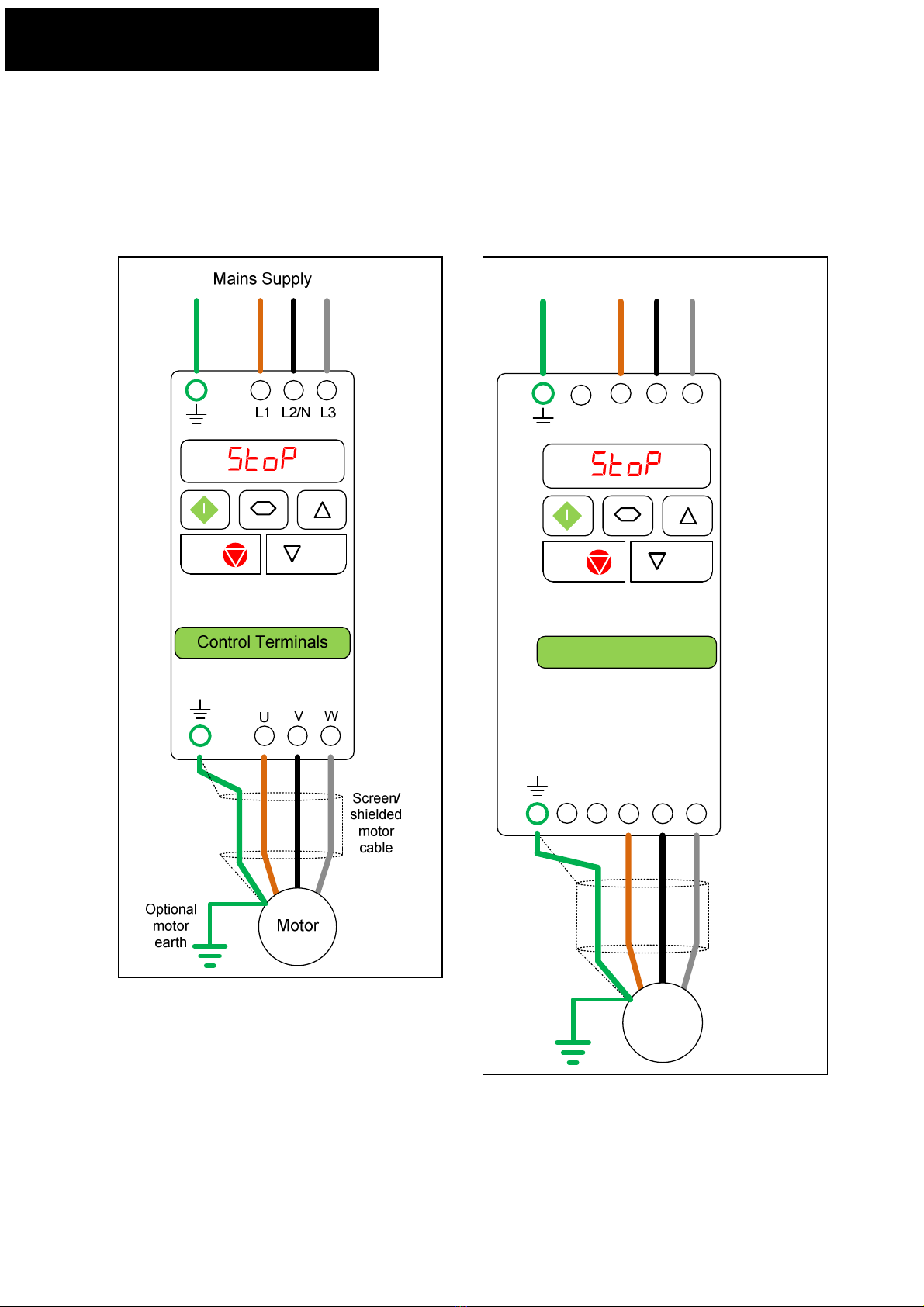

5

Power Terminals & Motor Connections

Power Terminals – E3 IP20

Size 1 – Mains suppl - model dependant

200V single phase input

200V three phase input

400V three phase input

Size 2, 3, 4 & 5 – Mains suppl - model dependant

200V single phase

200V three phase

400V three phase

NOTE: On E3 size 4 & 5, there are earth

connections on the drives heatsin at

the top and bottom of the drive

NOTE: For information on connecting

a bra ing resistor, see Section 15 –

Dynamic Bra ing

NOTE: Dynamic bra ing is not available

on size 1 drives

L1 L2/N L3

U V W

Motor

Mains Supply

Screen/

shielded

motor

cable

-D

+D BR

ontrol Terminals

Optional

motor

earth

Optidrive E3 Set-up Guide P a g e | 9

5

Power Terminals & Motor Connections

Power Terminals – E3 IP66

Size 1 – Mains suppl – Model dependant

200V single phase

200V three phase

400V three phase

Size 2, 3 & 4 – Mains suppl – Model dependant

200V single phase

200V three phase

400V three phase

NOTE: For information on connecting a bra ing resistor,

see Section 15 – Dynamic Bra ing

NOTE: Dynamic bra ing is not available

on size 1 drives

Screen/

shielded

motor

cable

L1 L2/N L3 U V W

Mains Supply

Motor

+D -DBR

ontrol Terminals

Optional

motor

earth

P a g e | 10 Optidrive E3 Set-up Guide

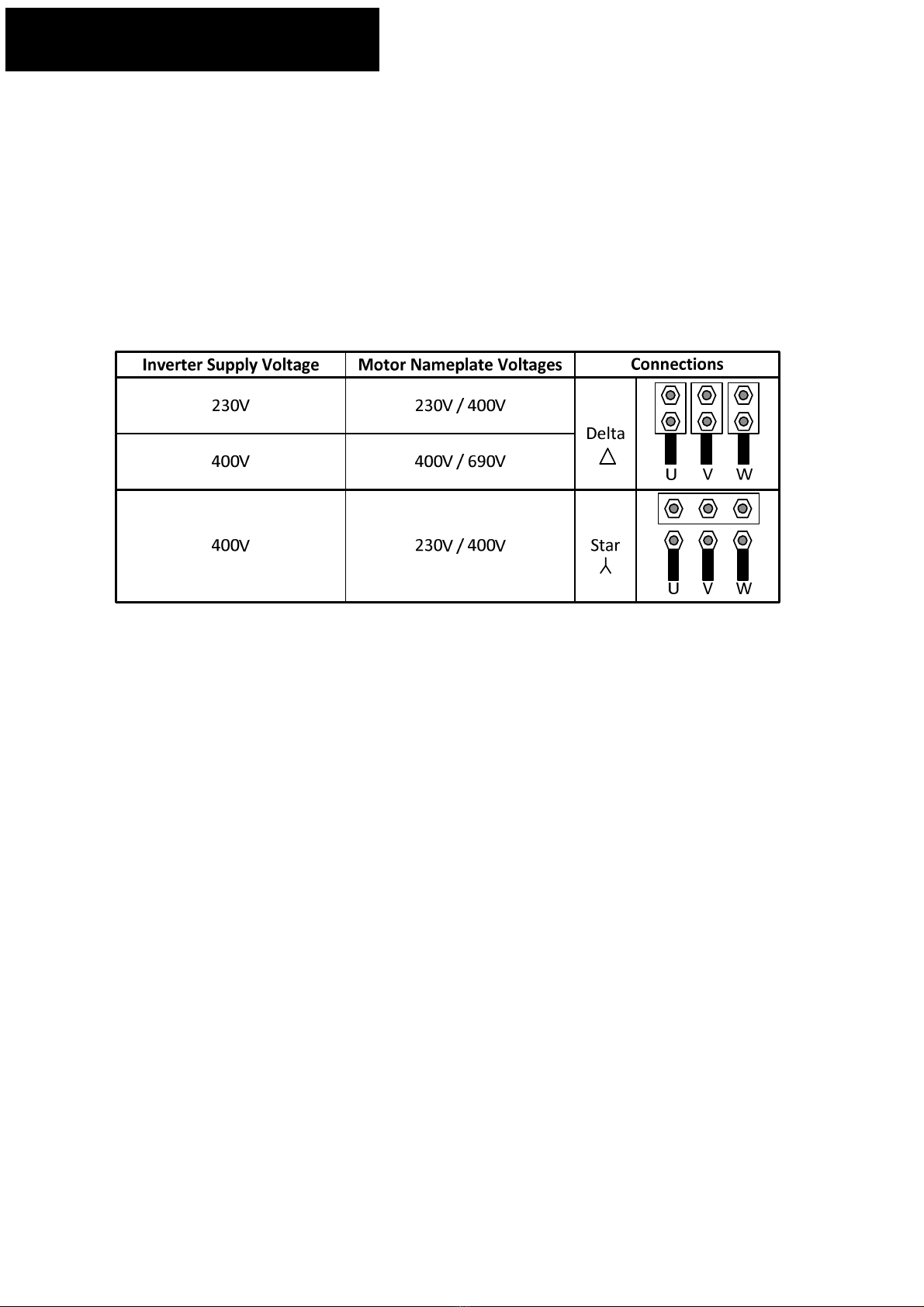

5

Power Terminals & Motor Connections

Motor Connections

When connecting a 3 phase motor to an AC inverter drive, it is important that the motor terminal box

connections are correct for the supply voltage being used.

Generally up to 3 W, the motor is wound for 230V delta, 400V star.

Generally above 3 W, the motor is wound for 400V delta, 690V star.

Please check our motor nameplate for the correct connection.

The usual issues when the wrong connections are made:

230V AC drive connected to a 400V star connected motor or 400V AC drive connected to a 690V star

connected motor:

The motor will probably run if starting a lightly loaded motor. If the motor tries to start a heavy load or if a

heavy load is applied to the motor while running, the motor will stall due to a lac of torque and the drive will

trip on an over current or I x t trip.

400V AC drive connected to a 230V delta connected motor:

On enable, the drive will either trip on an over current trip or the drive will go into current limit and trip on an I

x t trip.

Optidrive E3 Set-up Guide P a g e | 11

6

Basic EMC Information

Basic EMC Information

This section of this document gives some basic EMC information for the Optidrive E3.

Overview

The electromagnetic compatibility describes – according to the definition of the EMC directive – the capability

of a device to work satisfactorily in an electromagnetic environment without itself causing electromagnetic

interference which is unacceptable for other devices present in this environment . To guarantee that the

appropriate EMC standards are observed, the devices must demonstrate a sufficiently high noise immunity,

and also the emitted interference must be limited to acceptable values.

Product standard EN 61800-3 describes the EMC requirements placed on Variable-speed drive systems .

A variable-speed drive system (or Power Drive System PDS) consists of the Control/Power Module plus the

relevant electric motors including connecting cables.

The driven machine is not part of the drive system.

Environments

EN 61800-3 defines different requirements depending on the location where the drive is installed, designated

as a first and second environment. Residential buildings or locations where the drive system is directly

connected to a public low-voltage supply without intermediate transformer are defined as the first

environment. All locations outside a residential area are defined as the second environment. These are

basically industrial areas which are supplied from the medium-voltage network via their own transformers.

Category C1: Drive systems for rated voltages < 1000 V for unlimited use in the first environment.

Category C2: Stationary drive systems for rated voltages < 1000 V for use in the second environment. Use in

the first environment is possible if the drive system is operated and installed by qualified personnel. The

warning information and installation instructions supplied by the manufacturer must be observed.

Category C3: Drive systems for rated voltages < 1000 V for exclusive use in the second environment.

Optidrive E3 EMC Compliant Installation

Category Supply Ca le

Type

Motor Ca le Type Control

Ca les

Maximum Permissi le Motor Ca le

Length

C1 6 Shielded 1 Shielded 1,5 Shielded 4 1m / 5m 7

C2 Shielded 2 Shielded 1,5 Shielded 4 5m / 25m 7

C3 Unshielded 3 Shielded 2 Shielded 4 25m / 100m 7

1. A screened (shielded) cable suitable for fixed installation with the relevant mains voltage in use. Braided or

twisted type screened cable where the screen covers at least 85% of the cable surface area, designed with low

impedance to HF signals. Installation of a standard cable within a suitable steel or copper tube is also

acceptable.

2. A cable suitable for fixed installation with relevant mains voltage with a concentric protection wire.

Installation of a standard cable within a suitable steel or copper tube is also acceptable.

3. A cable suitable for fixed installation with relevant mains voltage. A shielded type cable is not necessary.

4. A shielded cable with low impedance shield. Twisted pair cable is recommended for analogue signals.

5. The cable screen should be terminated at the motor end using an EMC type gland allowing connection to

the motor body through the largest possible surface area. Where drives are mounted in a steel control panel

enclosure, the cable screen may be terminated directly to the control panel using a suitable EMC clamp or

gland, as close to the drive as possible.

P a g e | 12 Optidrive E3 Set-up Guide

6

Basic EMC Information

6. Compliance with category C1 conducted emissions only is achieved. For compliance with category C1

radiated emissions, additional measures may be required, contact your Sales Partner for further assistance.

7. Permissible cable length with additional external EMC filter.

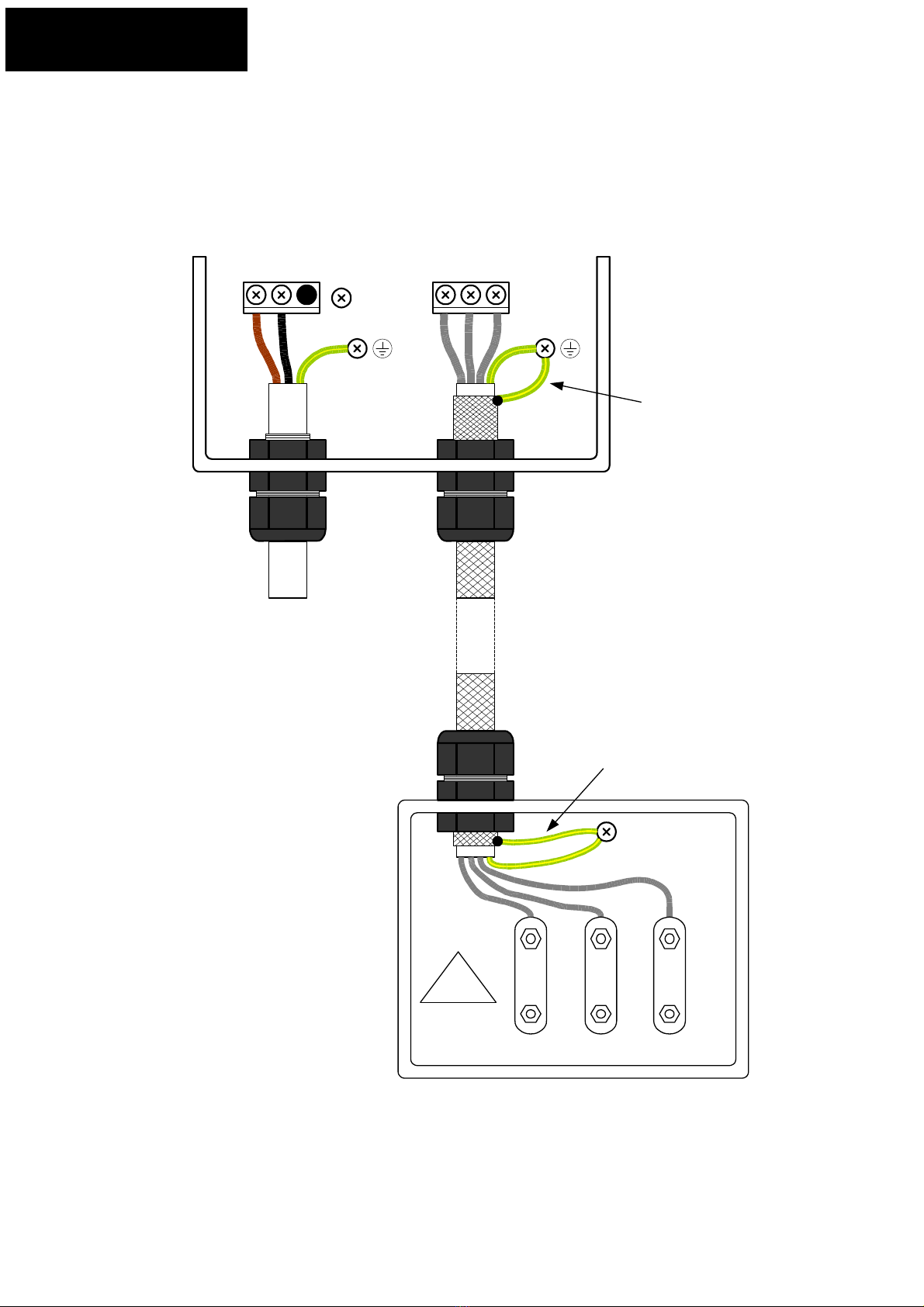

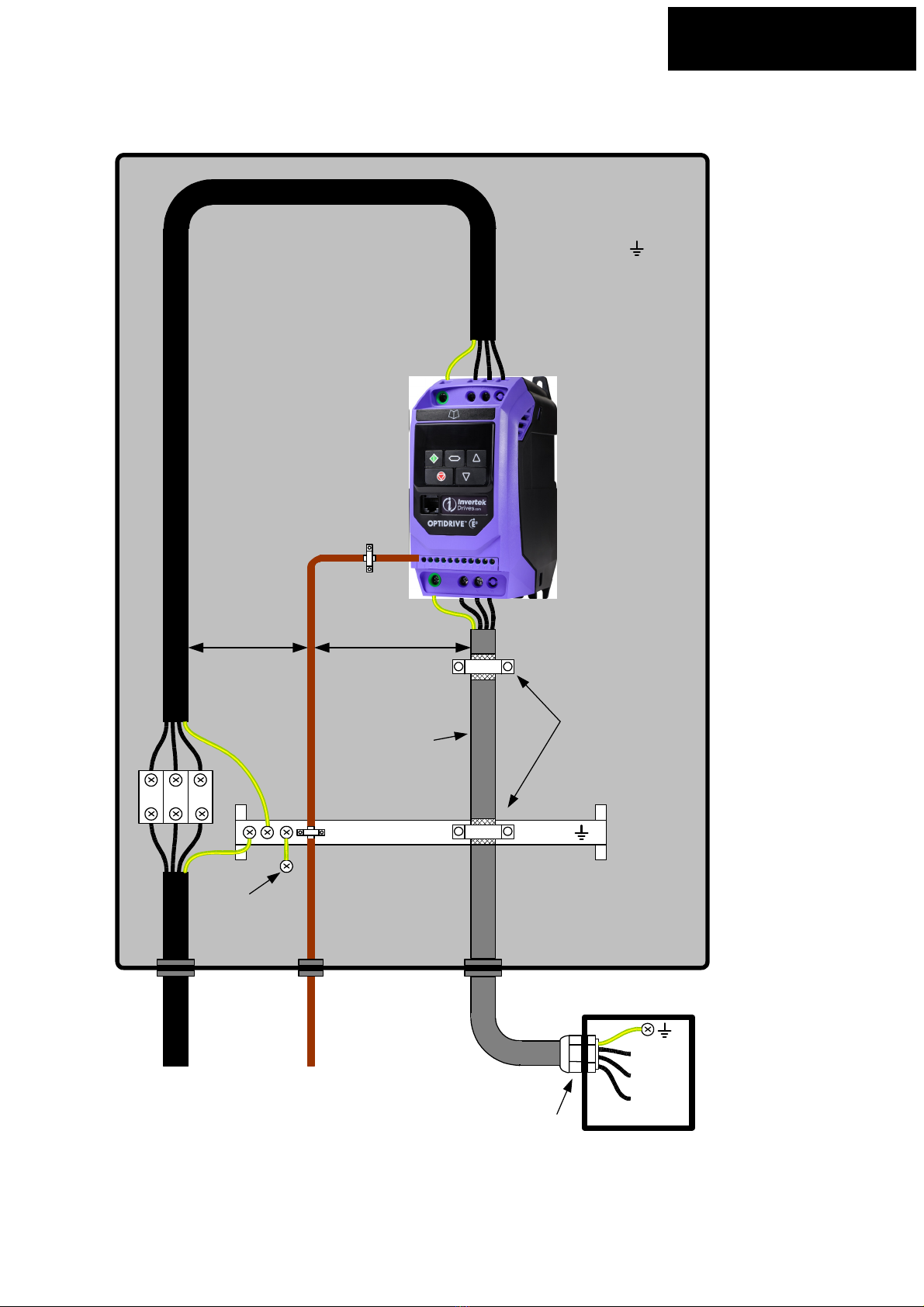

The following diagrams gives examples of connecting the E3 IP20 and IP66 Outdoor rated units for good EMC

performance

IP20 Power Wiring – Method 1

Motor

Cable

Motor Terminal

Box U1 V1 W1

Keep earth tails as

short as possible

Keep earth tails as

short as possible

Cable screen to cover at

least 85% of the cable

surface area

Motor

Cable

Motor connected in DELTA

(Please check motor rating for correct connection)

Optidrive E3 Set-up Guide P a g e | 13

6

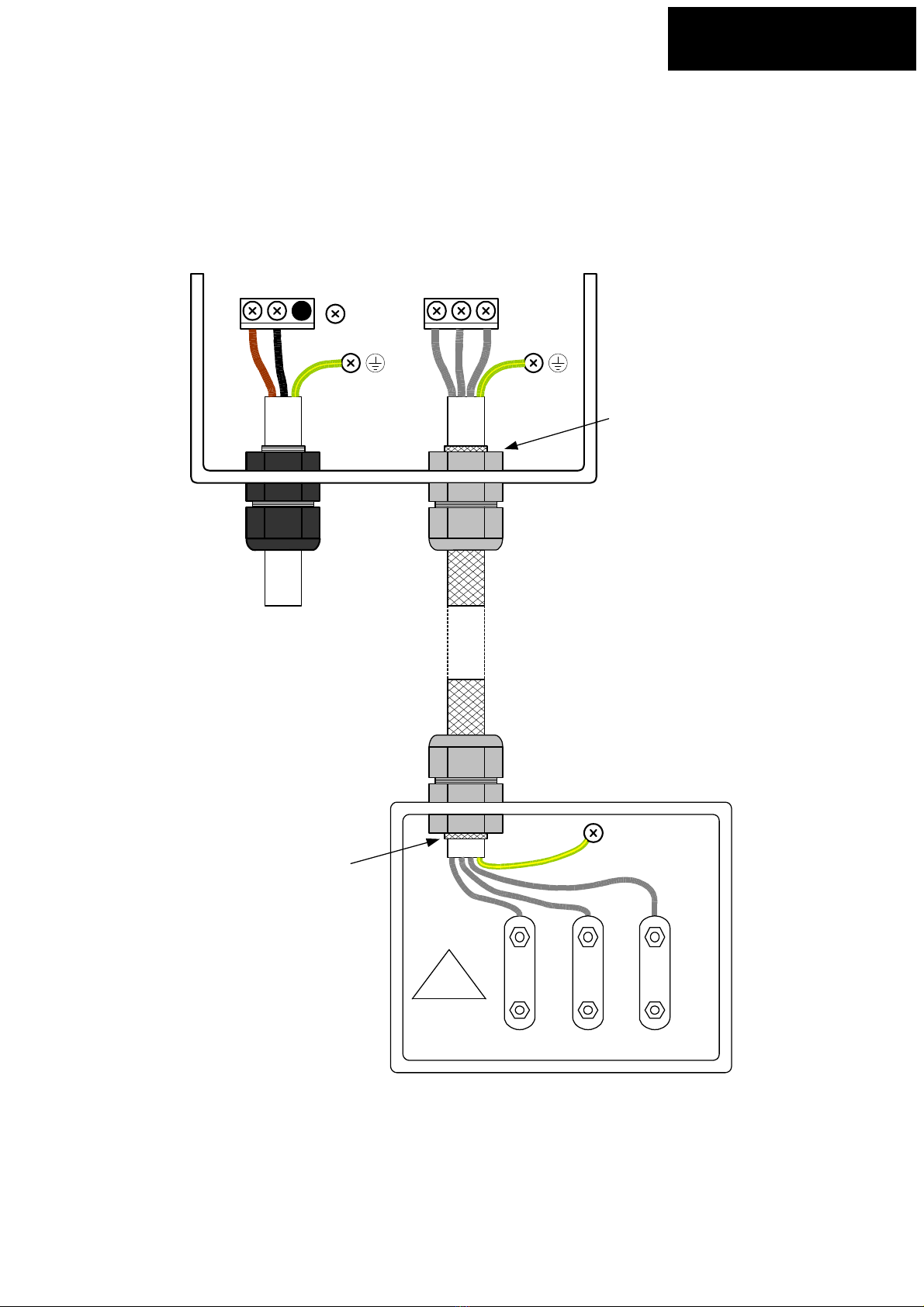

Basic EMC Information

IP20 Power Wiring – Method 2

Motor

Cable

Motor Terminal

Box U1 V1 W1

Keep earth cable as

short as possible

Keep earth tails as

short as possible

Cable screen to cover at

least 85% of the cable

surface area

Metal 'U' or 'P' clip to bond

cable screen to panel

backplate

Motor connected in DELTA

(Please check motor rating for correct connection)

Either use IP66 nylon cable

gland and connect screen to

earth terminal as diagram

or

use IP66 metal 'EMC' gland

fitted correctly in accordance

with manufacturers

guidelines

P a g e | 14 Optidrive E3 Set-up Guide

6

Basic EMC Information

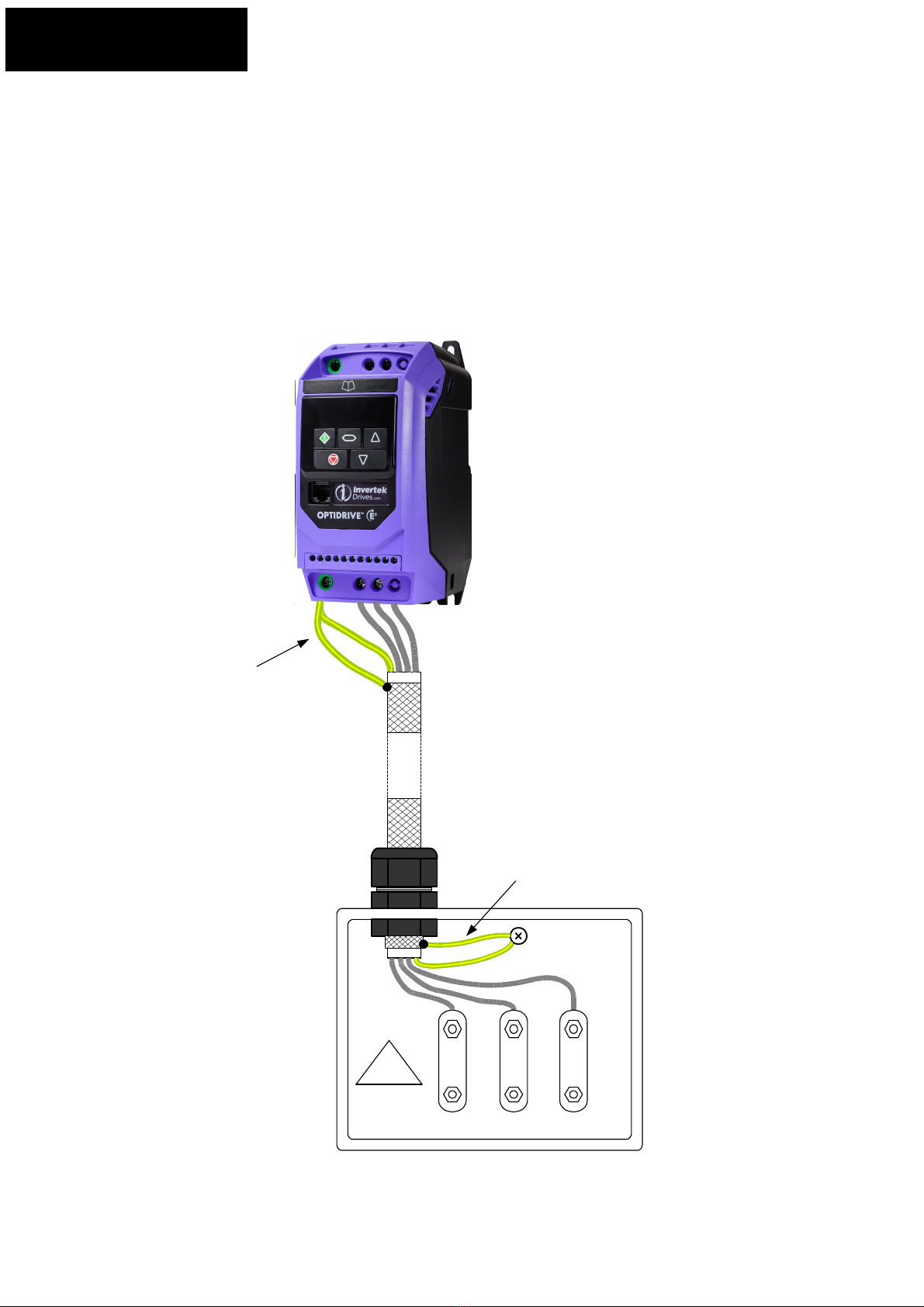

IP66 Power Wiring – Method 1

NOTE: Single phase input drive shown. Motor connections are the same for 3-phase drives.

L1/L L2/N L3 U V W

Mains

Supply

Cable

EMC

Motor

Cable

IP66 Nylon

Cable Gland

Motor Terminal

Box

Single

Phase

Supply

Motor

Terminals

U1 V1 W1

IP66 Nylon

Cable Gland

Keep earth tails as

short as possible

Keep earth tails as

short as possible

Cable screen to cover at

least 85% of the cable

surface area

Motor connected in DELTA

(Please check motor rating for correct connection)

IP66 Nylon

Cable Gland

Optidrive E3 Set-up Guide P a g e | 15

6

Basic EMC Information

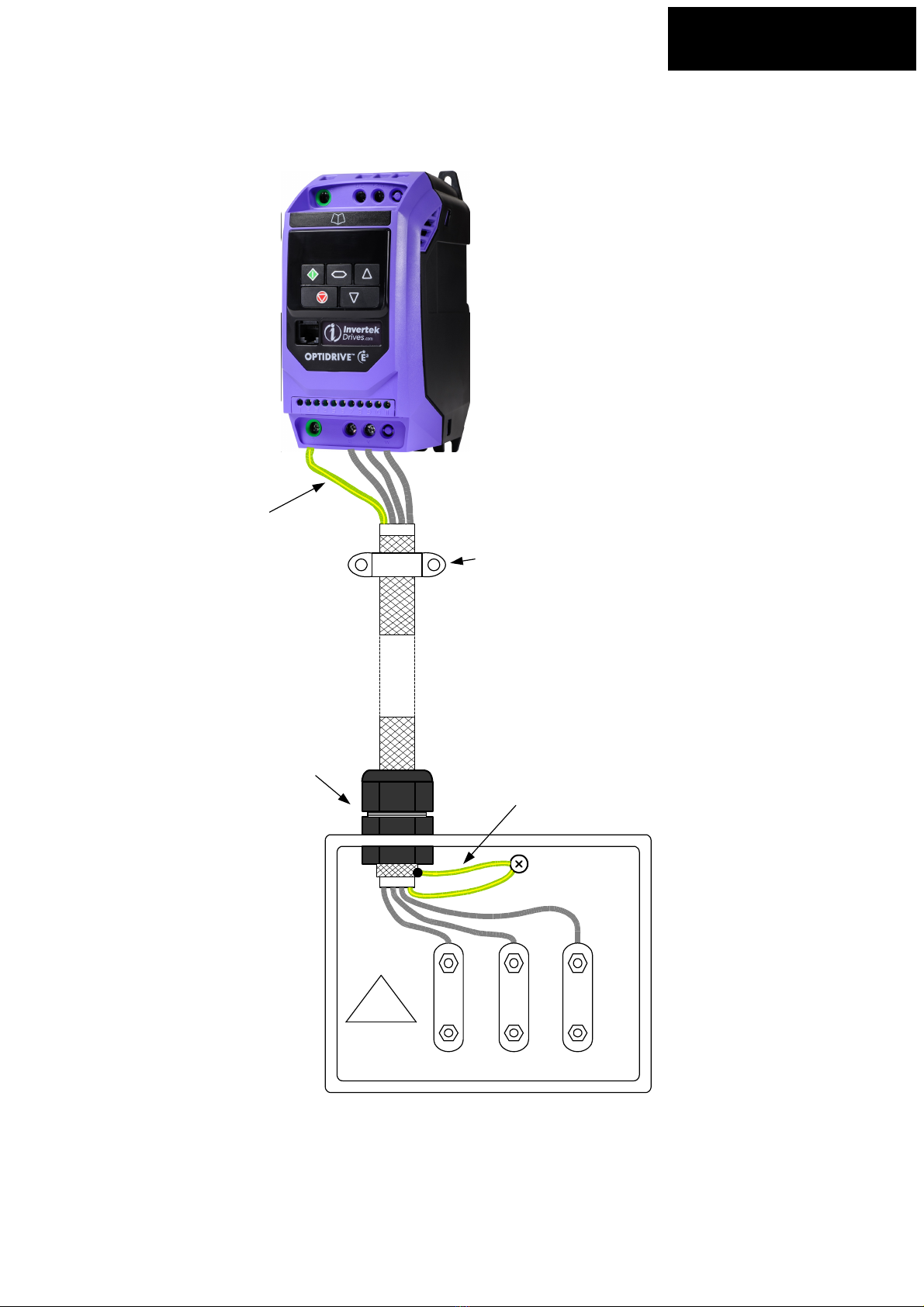

IP66 Power Wiring – Method 2

NOTE: Single phase input drive shown. Motor connections are the same for 3-phase drives.

L1/L L2/N L3 U V W

Mains

Supply

Cable

EMC

Motor

Cable

IP66 Nylon

Cable Gland

IP66 Metal

'EMC' Gland

Ensure EMC gland is fitted

correctly in accordance

with manufacturers

guidelines

IP66 Metal

'EMC' Gland

Ensure EMC gland is fitted

correctly in accordance

with manufacturers

guidelines

Motor Terminal

Box

Single

Phase

Supply

Motor

Terminals

Cable screen to cover at

least 85% of the cable

surface area

P a g e | 16 Optidrive E3 Set-up Guide

6

Basic EMC Information

Control Wiring

The following diagrams give examples of control wiring for good EMC performance

1 98765432 1110

+24V

DI 1

DI 2

DI 3 / AI 2

+10V

DI 4 / AI 1

0V

0V

DO 1 / AO 1

Status Relay

1 98765432 1110

DI 1

DI 2

DI 3 / AI 2

+10V

DI 4 / AI 1

0V

0V

DO 1 / AO 1

mA

+-

+24V

Status Relay

Optidrive E3 Set-up Guide P a g e | 17

6

Basic EMC Information

General requirements for good EMC practice

L1

L2

L3

Metal 'EMC' Gland

with cable shield/

screen connected to

gland as per

manufacturers

instructions

U

V

W

Mains Supply

Motor

terminal

box

Main earth busbar

Cable shield

exposed and

360

o

clamp

bonded to

metal backplate

or earth busbar

(Same for

control cables)

Motor Cable

3-phase and earth

shielded/screened

cable. Maintain

shield as far as

possible along cable

Control Cables

Twisted pair

shielded cables for

analogue signals

>100mm >100mm

Panel mounting

backplate with

conductive

surface

Metal backplate

bonded to main

earth busbar

P a g e | 18 Optidrive E3 Set-up Guide

6

Basic EMC Information

Braking resistor connections for good EMC practice

Cable shield

exposed and

360oclamp

bonded to

metal backplate

Panel mounting

backplate with

conductive

surface

Optional external

braking resistor

Optional external

braking resistor

Resistor thermal

overload protection

Resistor thermal

overload protection

Use screened cable if the

braking cable is leaving the

enclosure

Screened cable

Braking cable does not need

to be screened cable if not

leaving the enclosure. But

screened cable can be used

if so desired

Note: Some earth cables have been omitted for clarity. Please make sure braking resistor and case

are properly earthed.

This manual suits for next models

32

Table of contents

Popular DC Drive manuals by other brands

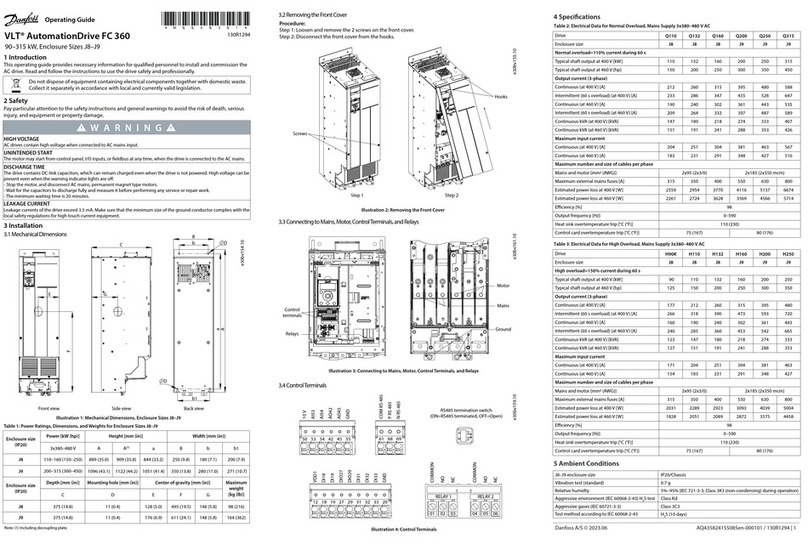

Danfoss

Danfoss VACON 3000 Application guide

Siemens

Siemens SINAMICS Equipment manual

KB Electronics

KB Electronics Penta Power KBRG-255 Installation and operating instructions

Santerno

Santerno SINUS H Series user manual

Digga

Digga PD Series Operator's manual

Omron

Omron SYSMAC CXONE-ALC-EV2 Series Operation manual