INS_FVT/FVR110_REV–

10/27/11

PAGE 8

© 2014 Communications Networks Corporation. All Rights Reserved. “ComNet” and the “ComNet Logo” are registered trademarks of Communication Networks, LLC.

3 CORPORATE DRIVE | DANBURY, CT 06810 | USA

T: 203.796.5300 | F: 203.796.5303 | TECH SUPPORT: 1.888.678.9427 | INFO@COMNET.NET

8 TURNBERRY PARK ROAD | GILDERSOME | MORLEY | LEEDS, UK LS27 7LE

T: +44 (0)113 307 6400 | F: +44 (0)113 253 7462 | INFO-EUROPE@COMNET.NET

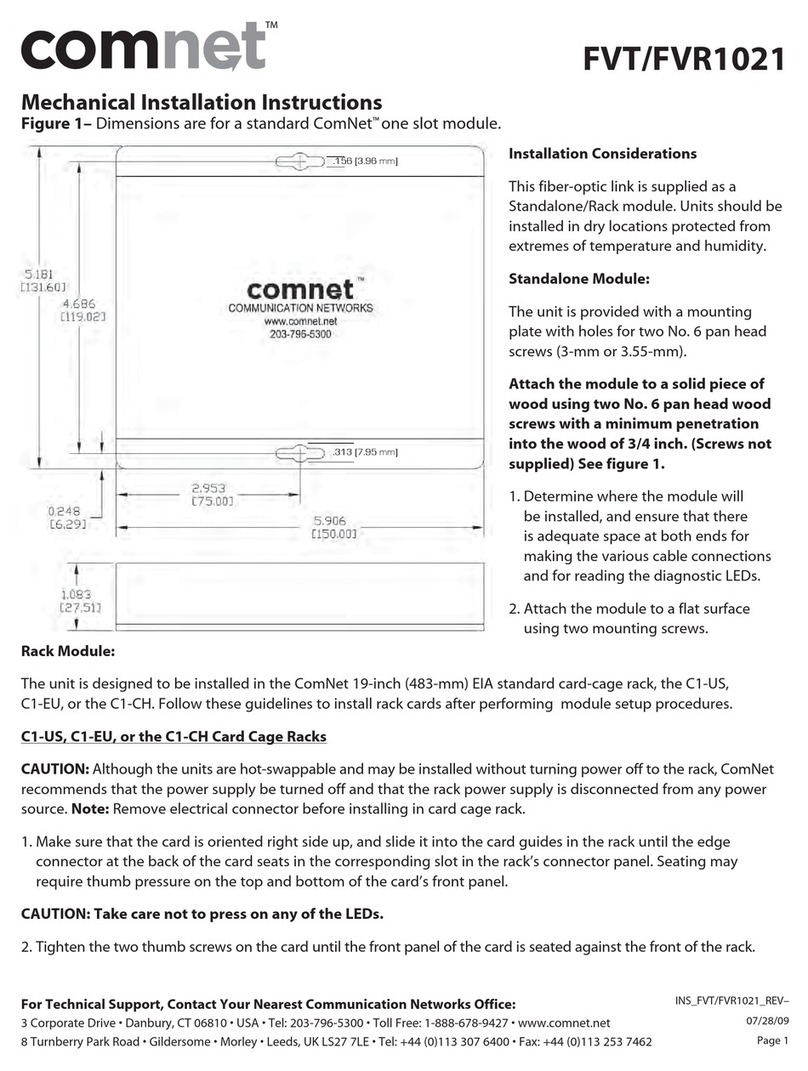

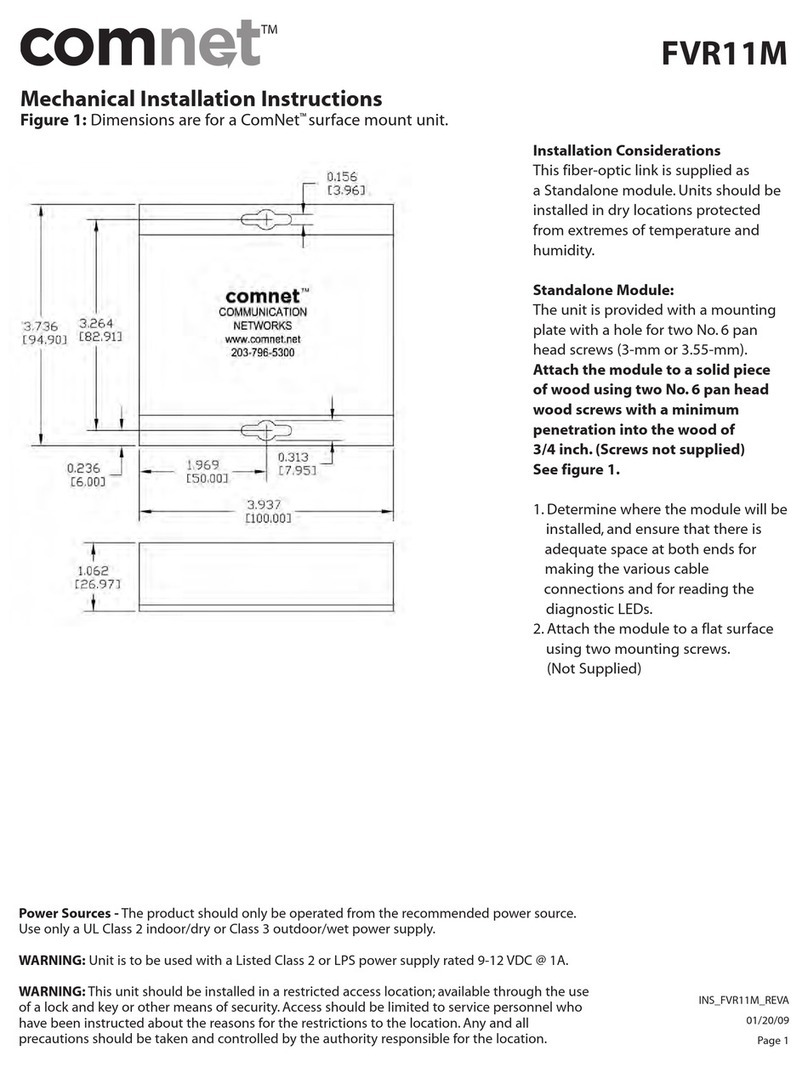

MECHANICAL INSTALLATION INSTRUCTIONS

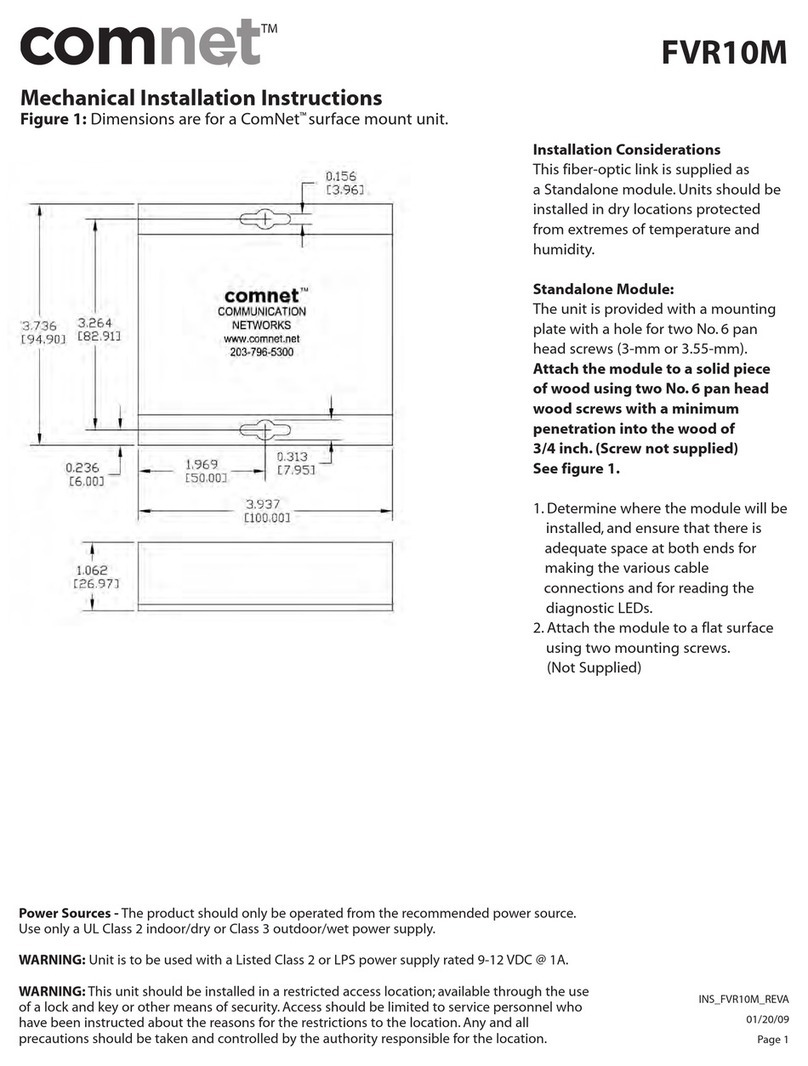

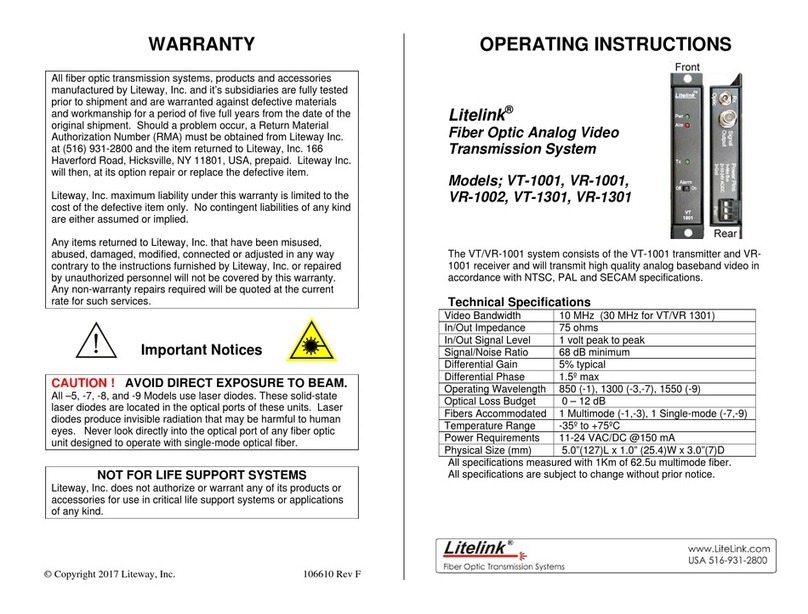

FIGURE A

Dimensions are for a standard ComNet™ one slot module

FIGURE B

Dimensions are for a ComNet™ mini long tall module

.156 [3.96 mm]

.313 [7.95 mm]

INSTALLATION CONSIDERATIONS

This fiber-optic link is supplied as a Standalone/Rack module. Units should

be installed in dry locations protected from extremes of temperature and

humidity.

C1-US, C1-EU, C1-AU OR C1-CH CARD CAGE RACKS

CAUTION: Although the units are hot-swappable and may be installed

without turning power off to the rack, ComNet recommends that the

power supply be turned off and that the rack power supply is disconnected

from any power source. Note: Remove electrical connector before

installing in card cage rack.

1. Make sure that the card is oriented right side up, and slide it into the

card guides in the rack until the edge connector at the back of the card

seats in the corresponding slot in the rack’s connector panel. Seating

may require thumb pressure on the top and bottom of the card’s front

panel.

CAUTION: Take care not to press on any of the LEDs.

2. Tighten the two thumb screws on the card until the front panel of the

card is seated against the front of the rack.

WARNING: Unit is to be used with a Listed Class 2 power supply.

IMPORTANT SAFEGUARDS:

A) Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may

be greater than room ambient. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum

ambient temperature (Tma) specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the equipment is not

compromised.

FVT/FVR110(M,S)[/M] Part Ordering Options:

(M,S): Fiber Type

M: Multimode

S: Singlemode

[/M]: Mini Long Tall Enclosure (optional)