10

STARTING UPTHEENGINE FORTHEFIRSTTIMEAND RUNNING IN

The first timeyou start it up, run the engine at2000 -2500 rpmforthe first 15 -20 seconds,then run it at

the lowestrevs(1500 rpm)forafewseconds,beforesteppingup the revsto3000 -3500 rpm.Atthispoint,

werecommend runninginthe engine beforeusingit,pushingthe engine toitsfull potential.Part ofthe

runninginprocess can be carried outinflight.Ifyou choosetodo soon the ground, ensurethe engine is

bolted securelyin position.

•Start the engine and run it at2500 to3000 rpmfor5minutes,then step up the revsto4000 rpmforone

minute before droppingto 3000 rpm.

•Repeatthe process, increasingthe revsto 4000.

•Settleat4500 rpmfor5minutes,then drivethe engine tothe maximumrevsfor10 secondsbefore

returningto 3000 rpm.

•Repeatthe above process, runningthe engine atmaximumrevsfor20 seconds.

•Repeatthe above process, runningthe engine atmaximumrevsfor30 seconds.

•Settleat3000 rpmfor5minutes,then at4000 rpmfor5minutes,then run atthe maximumrevsforone

minute and return to 3000 rpm.

•Run for2 minutesatmax. revs, then drop to 3000 rpm.

•Run for5minutesat4000 rpm,then 3minutesatmax. revs,returnto3000 rpmfor2minutes,then cut

off the powersupplyand stop the engine.

Duringthe above operations, checkthatthe temperature ofthe cylinderhead neverexceeds260°C(500F)

Duringthe running-in, it isparticularlydangeroustoincreasethe quantityofoil if you areusingCastrol

TTS. An excessive amountofoil will cancelthe benefits ofrunning-in the engine.

Duringthe first fewhours ofuse, neverapplyfull powerforprolonged periods,butjustforafewminutes

duringtake-off.Byrunning-inthe engine thoroughly,you will prolongitslife-span. The engine will loosen

up and function atfull powerafterapproximatelyfive hours.

Anyirregularitiesin the engine speed maybe caused bya badlyadjusted carburettor.

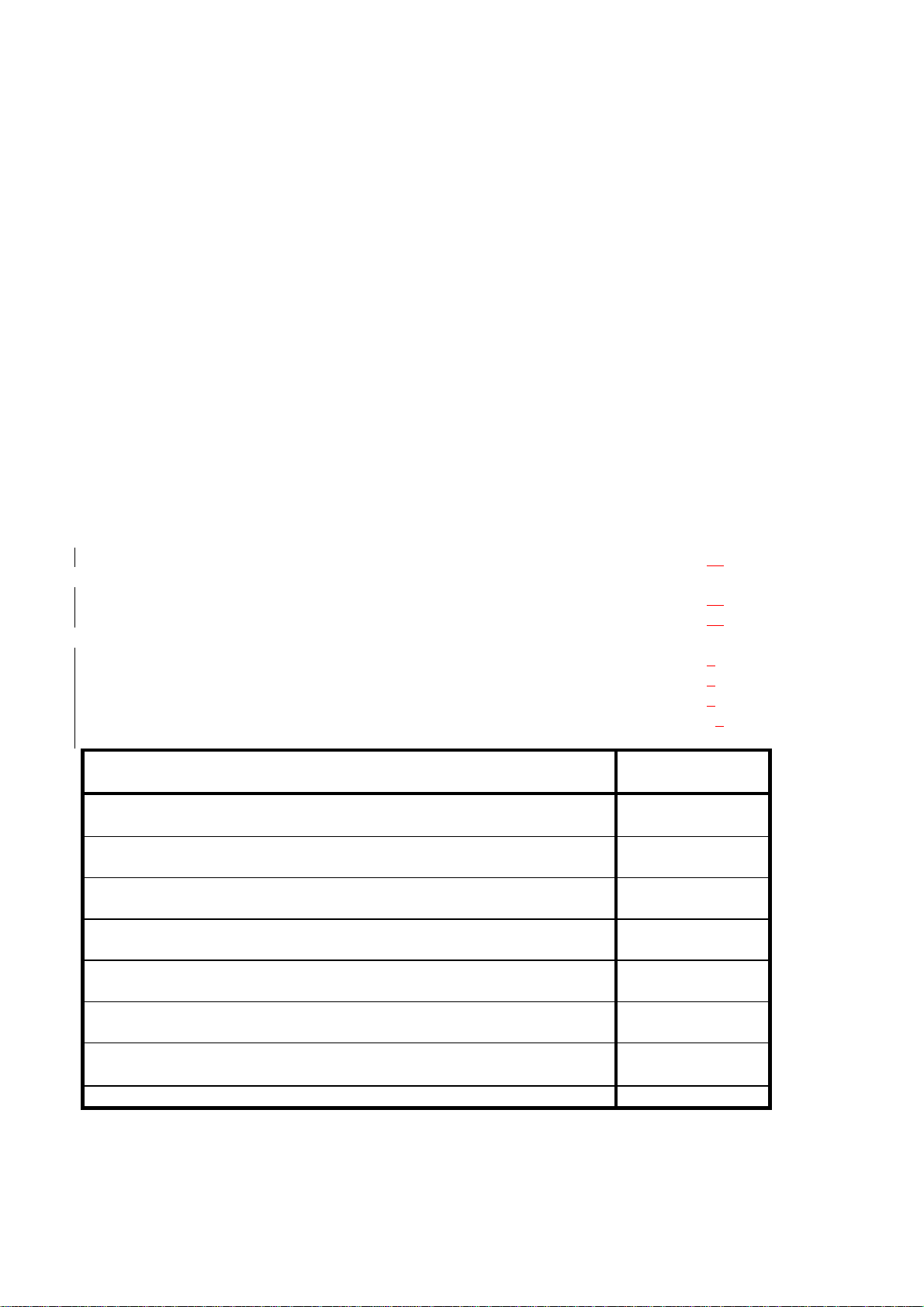

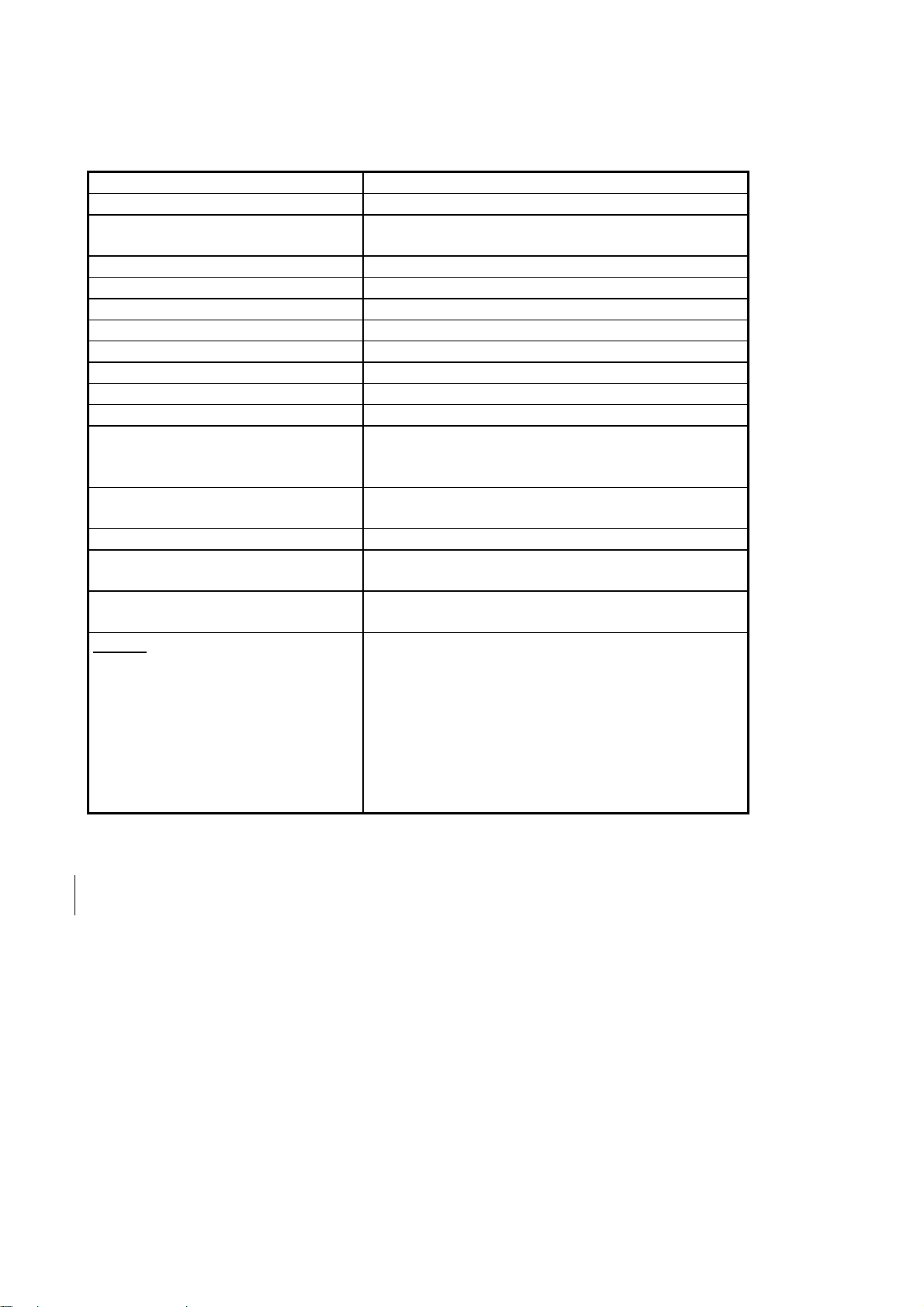

Afterthe first hourofuse, checkthatall boltsaretightlyfastened inaccordance withthe torque settings

given in the table on page 7.