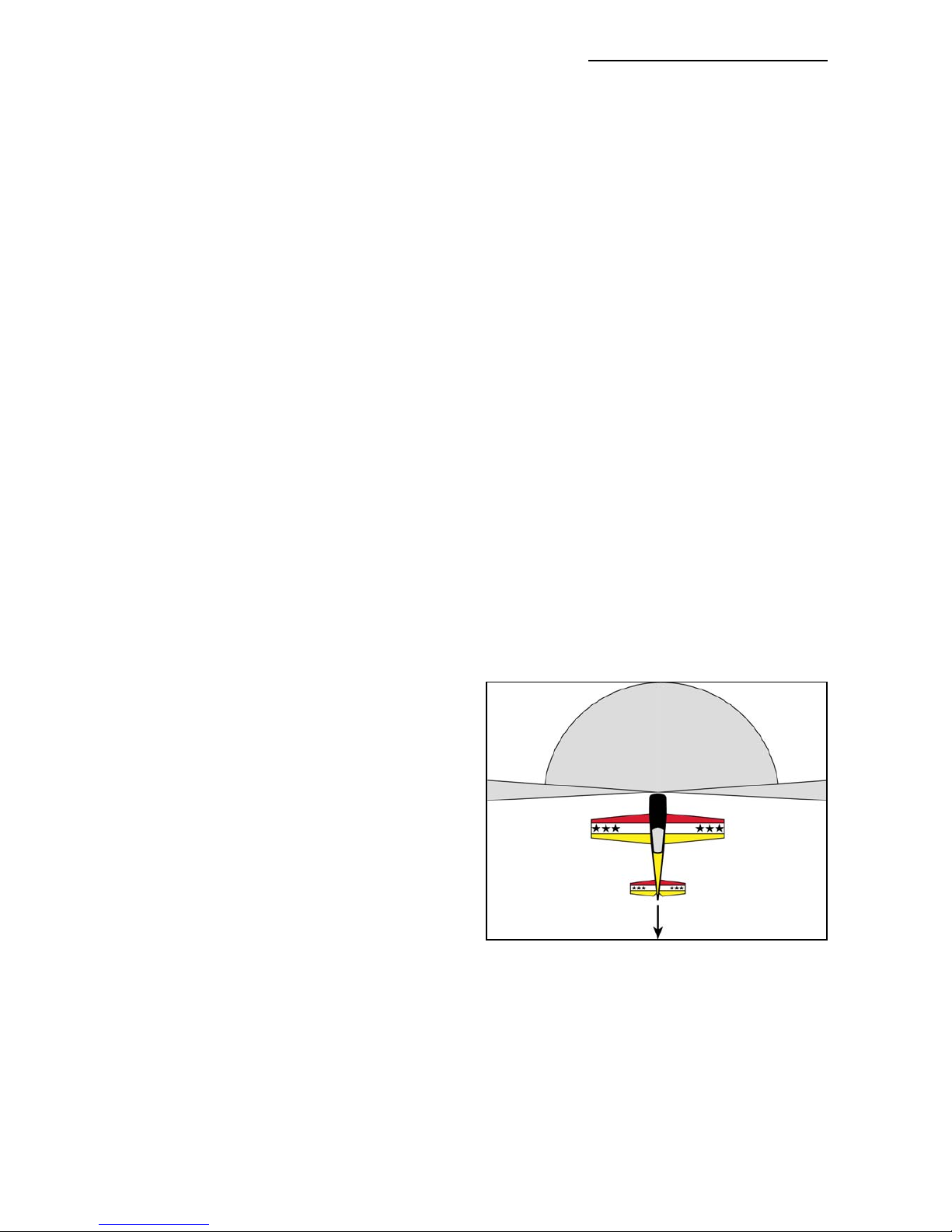

Why? Because the axis of the hinge is not at the centreline

of the aileron, so it moves slightly in and out when it trav-

els, and the aileron gets a little "bigger" in surface area

when moving up, and "smaller" when moving down. This is

why you have to set the negative differential in your trans-

mitter to compensate for the size changing. 10% is a good

starting point, and you will find out the exact setting during

the first flights, doing fast vertical rolls and watching the

fuselage rolling in a perfect line. You can set it perfectly, this

is guaranteed.

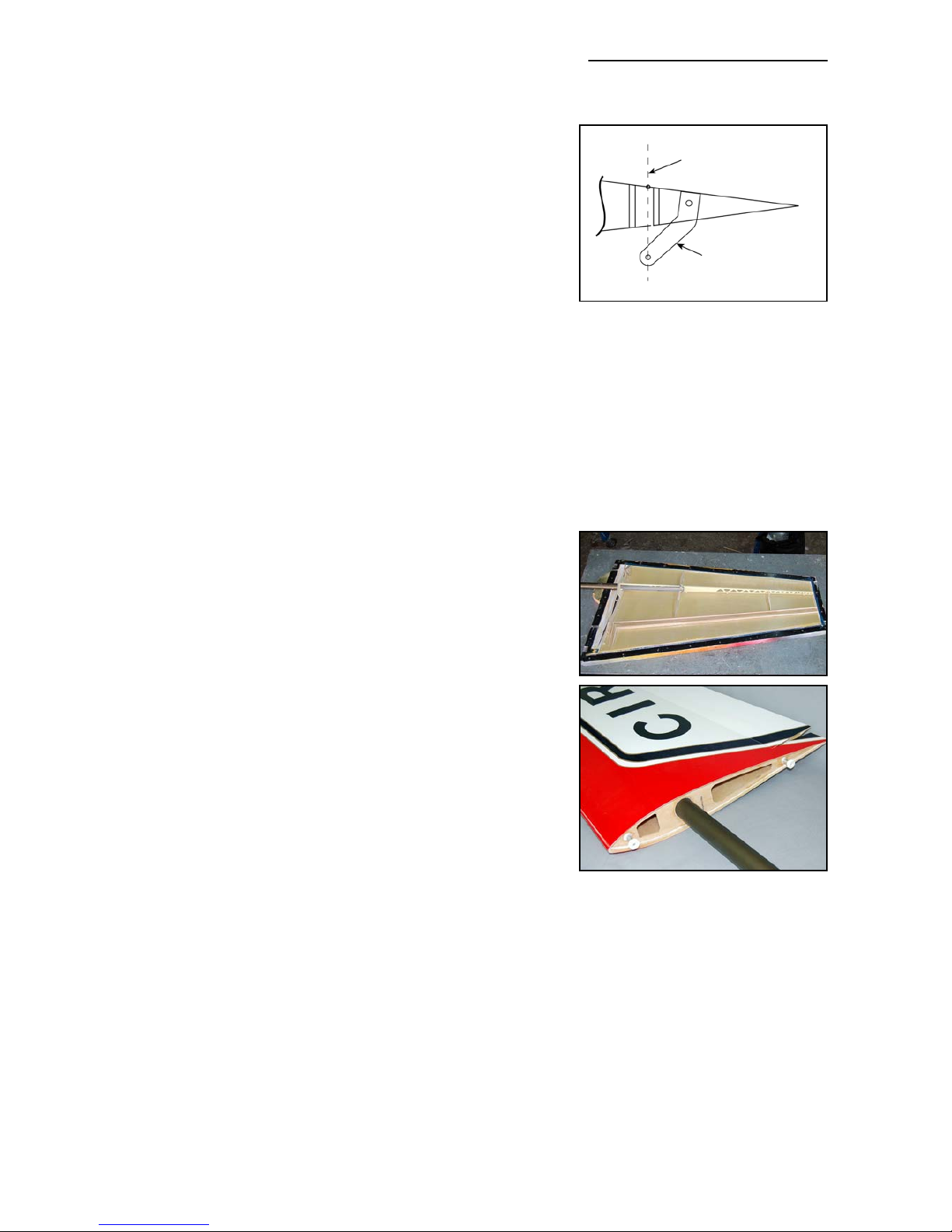

The bottom slot needs some explanation, too. The cut line is exactly in the correct position so

that the aileron slides under the wing skin smoothly. If the cut was a few mm forward or back, it

would not work properly. So, make sure that the lip is not damaged, and that the aileron slides

under this lip perfectly. It will NOT lock at any time, as long as the lip is not damaged. If damage

occurs to the lip, you can cut off 2-3 mm, but you should NEVER need to cut off more than this.

Make sure that the control horns are glued into the ailerons properly. The hole in the phenolic

horn for the quick-link needs to be exactly perpendicular to the hinge axis line, and in this

manual we show you a simple way to ensure that the horns in all pairs of control surfaces will be

identical, making it easy to set up your R/C for accurate flying manoeuvres.

The wings are already set-up with servo covers and hatch-

es for 2 servos per aileron, and we recommend a pair of

high-torque servos, like the JR D8411, in each wing. Our

servo covers and milled plywood mounts make both instal-

lation, and exchange if necessary, very quick and easy and

provide a rock solid servo mounting and linkage system.

The wings are attached to the fuselage with the 4 threaded

aluminium dowel anti-rotation pins, with 4 plastic nuts

inside the fuselage. If the aluminium dowels come loose in

the wing, the wing will slide outwards, away from the fuse-

lage, and the main spar tube will definitely break. So take

great care to inspect the glue joints of these anti-rotation

dowels in the wing REGULARLY. Excessive vibrations or

hard shocks can cause the glue joints to weaken or break.

Monitor these joints whenever you set up your plane. Never

forget to tighten the nuts inside the fuselage. Please DO

NOT modify these attachment dowels in any way, their per-

fect function is proven for many years.

The Fuselage:

The fuselage is also made in negative moulds, and is all constructed using TAVS technology. All

the loadbearing internal parts are installed during manufacture, to ensure accurate location and

reduce your assembly time. The fibreglass tubes in the wings to receive the wing spar tube, the

stab spar tubes, and the holes and reinforcement plates for the anti-rotation dowels, are already

installed. There is no need to even check the incidences - you can be assured that these are

already set in the moulds so that no adjustment is necessary.

The landing gear mount is strong and doesn’t need any extra reinforcement. The fuselage is

extremely light weight, and the gear loads need to be led into the structure gently. No glue joint

needs to be stronger than the materials that it is attached to, as it would just result in increased

weight for no advantage. The landing gear is a fairly flexible design, which works very much like

5

Centreline of hinge axis

Phenolic control horn