4

NOTE: The Model No. KFHP Series Hot Plates are not ETL

Certified Designs.

All FHP Series, STFHP Series, and KFHP Series Hot Plates

are for use in combustible and non-combustible locations when

installed on a non-combustible counter.

The BTU input rating on all equipment is calibrated for elevations

up to 2,000 feet above sea level. All orifice drill sizes are

referenced for operation at or below this altitude. For operation

at elevations above 2,000 feet, the BTU rating must be reduced

4% for each 1,000 feet of elevation or the orifice drill size must be

changed appropriately. For high altitude drill sizes, call your local

gas company or Factory Authorized Service Center.

All units are equipped with fixed orifices and cannot be adjusted.

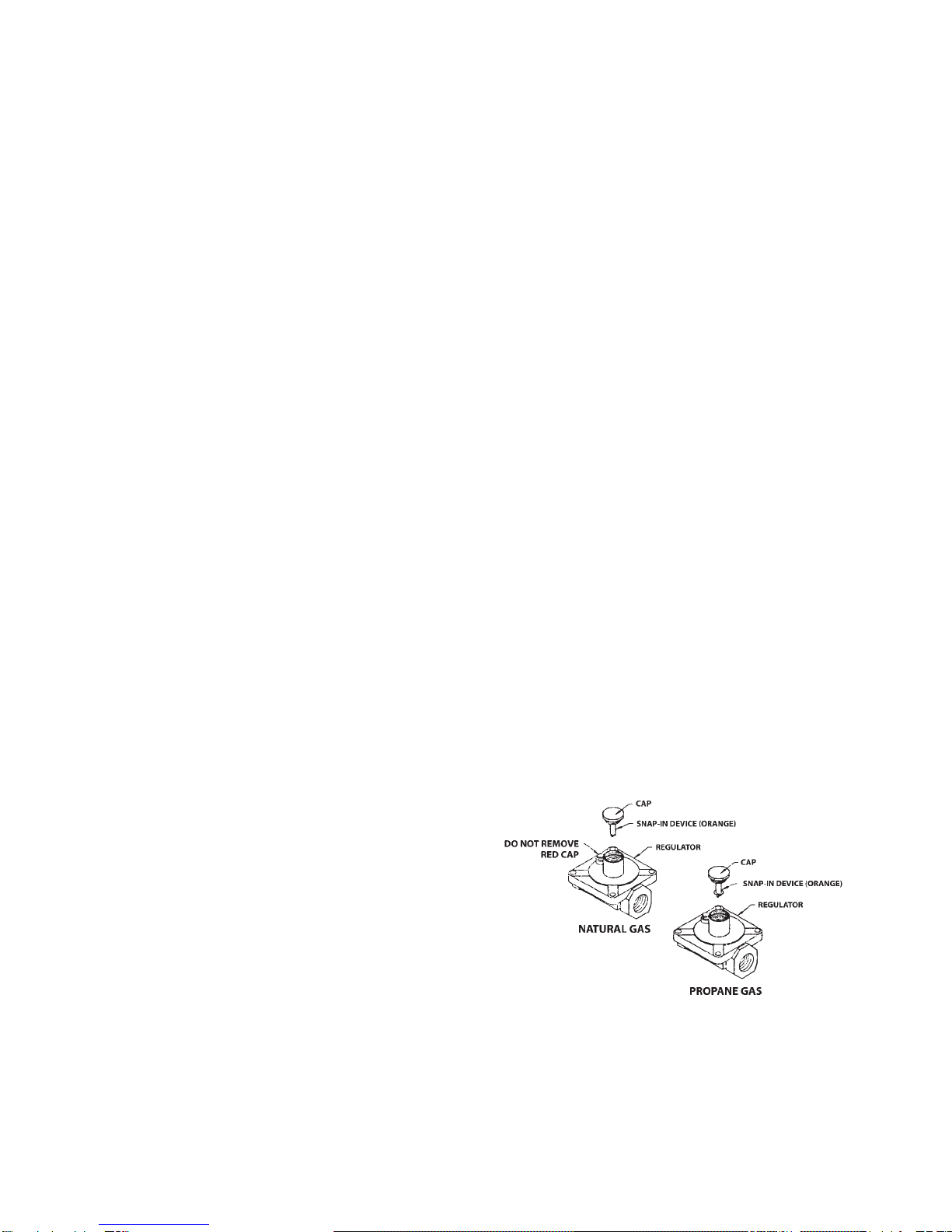

If converting the gas appliance from natural to propane, or vice

versa, all orifices and the regulator must be changed. The correct

type of gas, for which the unit is configured, is noted on the

name plate. The type of gas specified MUST be used. For proper

conversion, contact a qualified service technician or your Factory

Authorized Service Center.

When installed with casters, adequate means of restraint must

be provided to limit the movement of the appliance without

depending on the connector and the quick disconnect device or its

associated piping to limit the units movement. The restraint should

be securely fastened to the back of the unit. If disconnection of

the restraint is necessary, the restraint must be reconnected after

the appliance has been returned to its original installation position.

For a gas appliance that is equipped with casters, the installation

shall be made with a connector that complies with the Standard

for Connectors for Moveable Gas Appliances, ANSI Z21.69 -1987,

and addenda Z21.69a -1989, and a quick disconnect device

the complies with the Standards for Quick Disconnect Devices

for Use With Gas Fuel, Z21.69 latest edition and Z21.41 - latest

edition.

Provisions shall be made in the design of the kitchen, to

ensure an adequate fresh air supply for proper ventilation and

combustion.

Do not obstruct the flow of combustion gases or ventilation air.

Never enclose the bottom of the unit with a raised curb and /or

any other construction that would obstruct the air flow into unit.

One of the most important considerations in the installation of this

unit is ventilation. A commerical gas appliance must be installed

so that the products of combustion are efficiently removed.

However, the kitchen ventilation system must not produce a draft

that would interfere with the proper operation of the burners.

The area around this and any other appliance must always

be kept free and clear of combustibles such as: grease, food

particles, fuel, solvents, cleaning fluids, gasoline, mops, rags, and

etc.

During installation, use thread compound sparingly. Always

use a compound that is impervious to chemical reaction with

propane gases. NEVER put any of the compound on the first two

outer threads. This will minimize the possibility of the compound

breaking free and clogging the pilots, burner orifices, and controls.

When a commerical gas appliance is first installed, the gas

pressure must be checked with a manometer by a qualified

service technician. This will ensure that the existing gas facilities

will deliver the BTU’s of gas required on the rating plate.

WARNING - If the appliance in configured for LP Gas, never

connect the equipment directly to the pressure tank. Damage

will result to the appliance if the tank pressure is not properly

regulated. The regulator supplied with your unit is a low pressure

(1/2 PSI max.) appliance regulator. For proper pressure regulation

specifications, consult your local Factory Authorized Service

Agency or an LP Gas Distributor.

INSTALLATION

THIS APPLIANCE IS INTENDED FOR OTHER THAN

HOUSEHOLD USE

All Comstock-Castle commerical gas appliances are manu-

factured by skilled craftsman using the finest quality materials.

PROPER installation by qualified personnel is essential for safe,

efficient, and trouble-free operation of the unit. Any alteration

and/or tampering, without proper knowledge, tools, and test

equipment, is DANGEROUS and will void all warranties.

The installation must conform with local codes, or in the absence

of locel codes, with the National Fuel Gas Code, ANSIZ223.1

- latest edition.

PRESSURE TESTING:

FAILURETO INSTALL PRESSURE REGULATOR WILLVOID

WARRANTY. (Most units have a convertible regulator.)

The appliance and its indivdual shut-off valve must be dis-

connected from the gas supply piping system during any

pressure testing of that system at test pressure in excess of

1/2 psig (3.45 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.45 kPa).

NOTICE

The proper installation of this gas appliance is the total

responsibility of the end user.

It is the responsibility of the purchaser to determine that the

installer is qualified in installation procedures. Conversion,

connecting gas lines, calibrating thermostats, burners, lighters,

setting gas pressure with manometer, and etc., is all part of

normal installation and will not be paid for under warranty. If a

warranty technician is called out and finds the unit improperly

installed, the end user may be subject to billing.

FOR MAINTENANCE, SERVICE, REPAIRS, OR

INSTALLATION - Contact your dealer or the factory, for your

local Factory Authorized Service Agency.

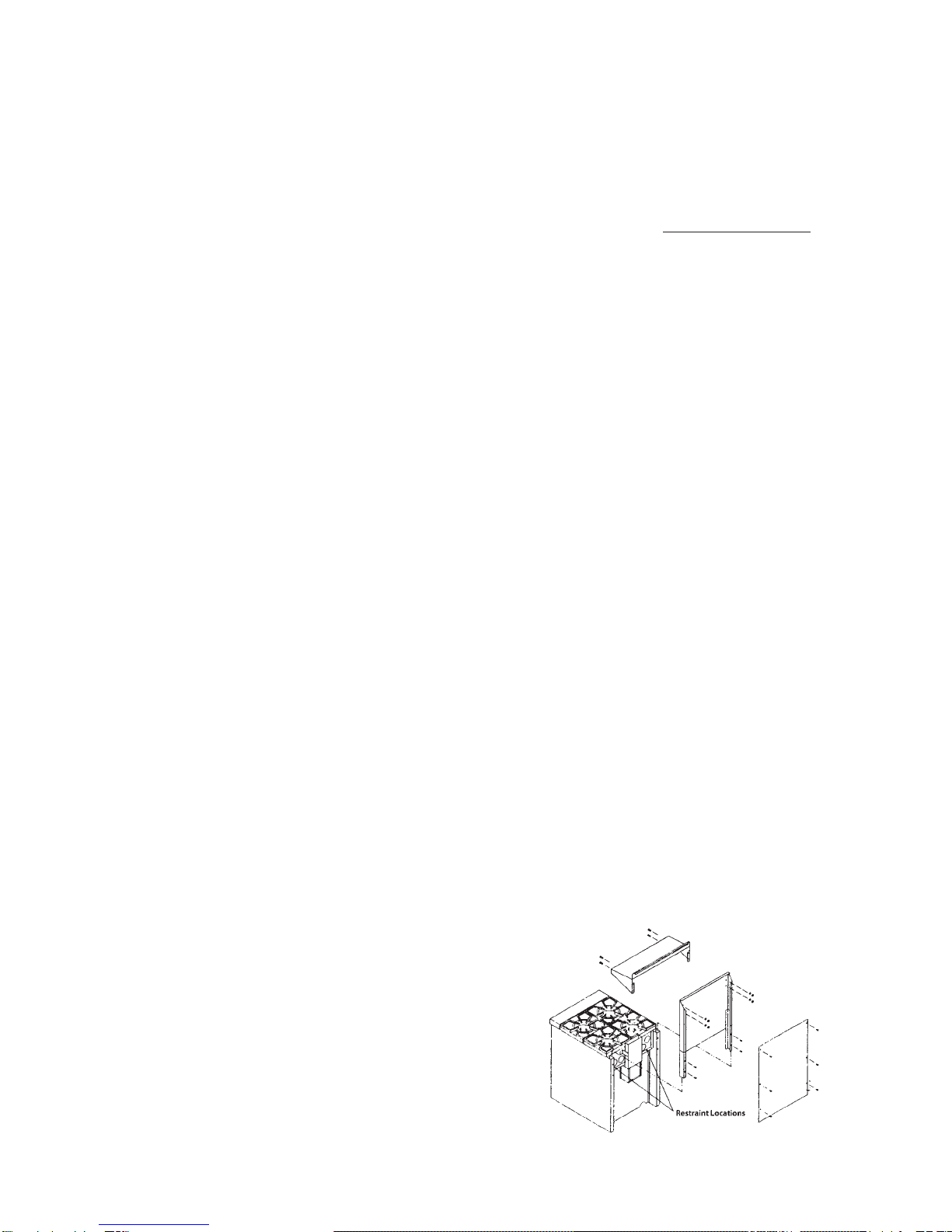

INSTALLING THE BACKSPLASH OR HIGH SHELF:

To install a backsplash or high shelf on a Comstock-Castle Range,

proceed as follows:

1. Ensure back of unit is easily accessible.

2. If mounting low back (backsplash), slide into supports on back

of unit, and secure with #10 x 5/8” sheet metal screws.

3. If mounting high shelf, mount shelf to high back using #24 x

3/4” machine screws with nut and washer.

4. Slide backsplash into the side-supports on back of unit, and

secure with #10 x 5/8” sheet metal screws. (Fig. 1)

Figure 1