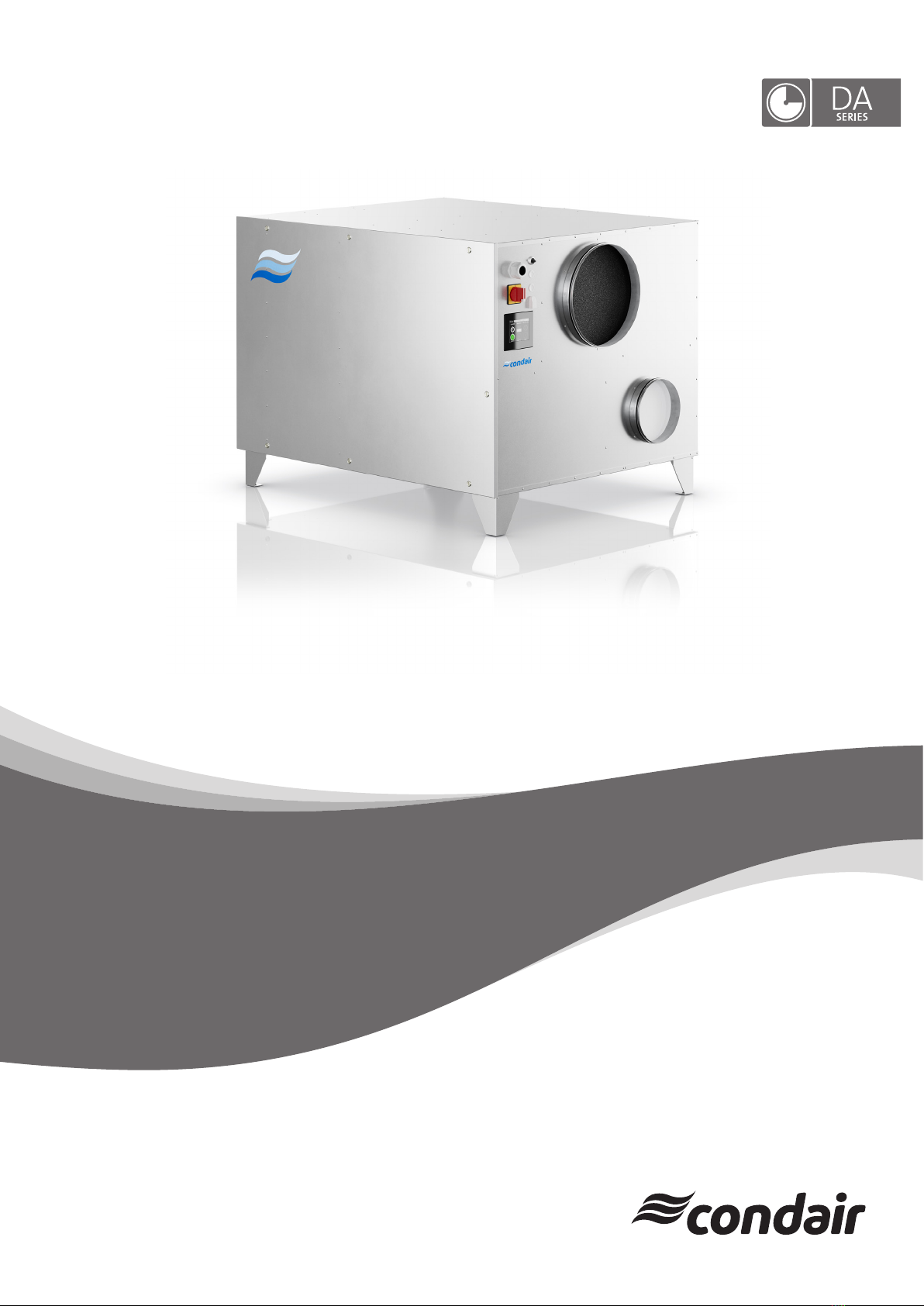

10 Product overview

4.4 Product description

The Condair DA 500-4000 Compact desiccant dryers with applied ducting meet the requirements of IEC

protective class IP23. The electrical panel meets the requirements of IEC protective class IP44.

4.4.1 Casing

The housing is powder coated in RAL7035 and is made from 1 mm thick Aluzinc®. The construction with

sealing material on the panel and internal construction achieves high tightness.

The service-friendly design allows easy access to internal components via a removable front panel. All

air duct connections are prepared for the connection of standard spiral ducts.

4.4.2 Rotor

The desiccant dryer has a drying rotor made of 82% desiccant silica gel, 16% breglass and 2% adhe-

sive sealant. The rotor has a matrix of corrugated and at heat resistant sheets, which houses the Silica

Gel desiccant agent. This matrix creates a large number of axial utes through the rotor, which together

builds up an immense surface area for moisture adsorption in a small volume. The rotor is manufactured

and processed to be able to withstand moisture-saturated air without being damaged. Furthermore, the

rotor will not be damaged even if the fan or the heater for reactivation should fail during operation. The

desiccant rotor is tested according to ASTM E84-18b, and the results are Flame Spread Index (FSI) 0

and Smoke Developed Index (SDI) 0.

Rotor sealings

The rotor has two peripheral seals (PTFE/Silicone) on the rotor casing and four radial seals (PTFE)

Rotor drive system

An electrical gear motor and a belt drive achieve the slow rotation of the rotor. The belt sits on the outer

rim of the rotor and is driven by a pulley on the drive motor. A belt tension device keeps the belt in place

and maintains tension to prevent belt slip. Correct operation of the drive system, and direction of rotation

can be checked by opening the front panel.

The centre hub of the rotor is equipped with ball bearings. The rotor shaft is made from stainless steel.

4.4.3 Airlters

Two separate air lters class ISO coarse ≥65% are installed on the inlet of each air ow. These lters

protect primarily the internal components from dust.

4.4.4 Fans for process- and reactivation air

The device is equipped with two directly driven centrifugal fans, IP54 and ISO F, installed in the device.

The exact type can be found in the respective wiring diagram.