2

Congratulations on your purchase of the thermal imaging camera IR-CAM4

CONDTROL.

Safety instructions provided in this user manual should be carefully read before

you use the product for the first time.

1. SAFETY REGULATIONS

The user manual should be read carefully before you use the product for the first

time. If the product is given to someone for temporary use, be sure to enclose

user manual to it.

- Do not misuse the product.

- Store the product beyond reach of children and unauthorized people.

- It is prohibited to disassemble or repair the product yourself. Entrust product

repair to qualified personnel and use original spare parts only.

- Never point the lens directly toward a strong radiation source (ie. Sun, direct or

reflected laser beam, etc.), with power on or power off, as damage may result to

the thermal detector used inside. Permanent damage may result!

- Store the unit in its original case in a cool, dry, well-ventilated area away from

strong electromagnetic fields.

- Protect the surface of the lens from being stained or damaged by foreign objects

such as sludge or chemicals. Please replace the lens cap after use.

- Do not use the product in explosive environment, close to flammable materials.

- Protect the product from exposure to high temperature, for example, prolonged

heating in the sun, fire, water and moisture.

- It is prohibited to disassemble, incinerate or puncture the battery

- Do not short circuit the battery

- Avoid heating the battery to avoid the risk of explosion.

- Remove the battery from the device if it not used for a long time.

- Do not leave discharged battery in the device.

2. FUNCTIONS/APPLICATIONS

IR-CAM4 CONDTROL is a multifunctional thermal imaging camera intended for

non-contact measurement of the object surface temperature. It is designed to

meet the requirements of service organizations, construction companies, service

providers. IR-CAM 3 CONDTROL combines professional features, intuitive

operation and a wide range of measured temperatures.

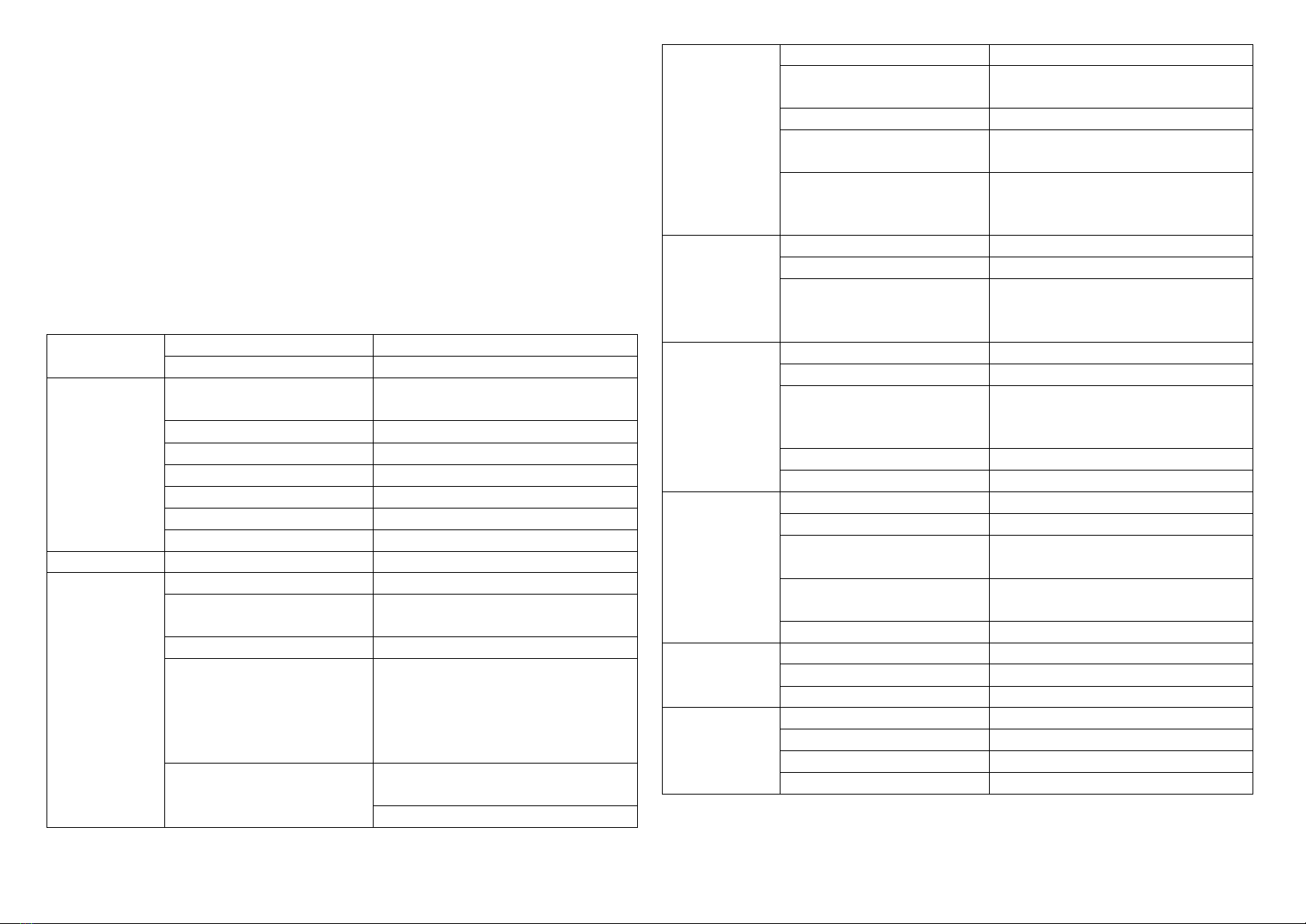

Features:

-User selectable Auto or manual level and span control

-°C, °F or K measurement scale

-6 user selectable color palettes

-11 user selectable languages

-Hot temperature spot measurement

-Cold temperature spot measurement

-1 removable spot measurements

-High temperature alarm setting

-T Reflect - Reflected temperature compensation

-2X digital zoom

-Freeze screen for viewing current image

-Video Output –NTSC or PAL

-1 Area measurement

-Image storage via TF card

-T Correct –Measurement Offset correction

-Built in Emissivity Table list of common materials

Applications:

1) Preventive maintenance

-Power industry: Power line and power facility thermal state checking;

problem and defect diagnosis.

-Electrical system: Identify potential circuit overloads.

-Mechanical system: Reduce downtime and avoid catastrophic failure.

2) Construction science

-Roof: Quick identification of water penetration problems.

-Structure: Commercial and residential energy audits.

-Moisture detection: Determine root cause of moisture and mildew.

-Evaluation:Evaluate the resolution to ensure the area completely dry.