Operation Manual

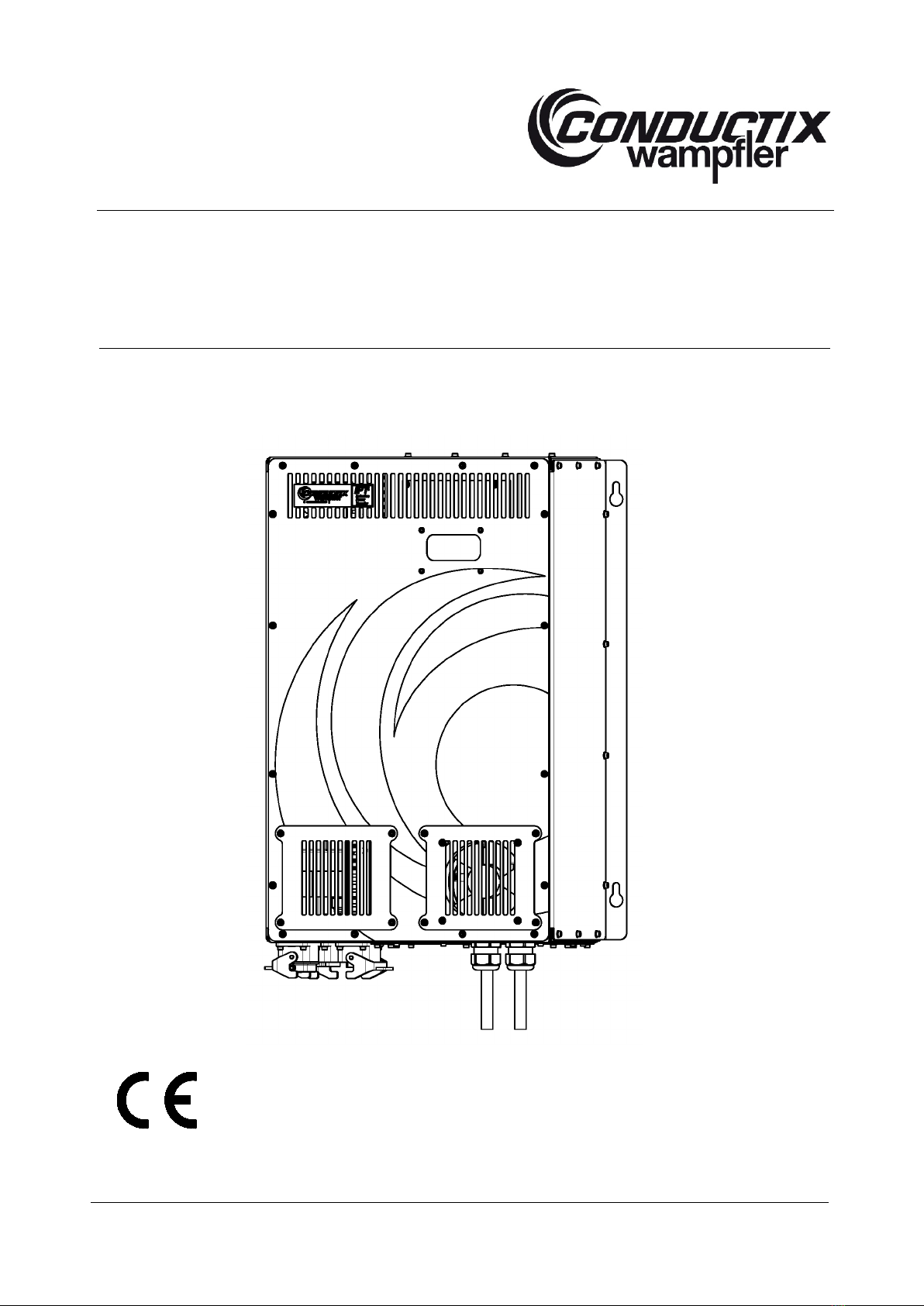

Track Supply 16 kW Module

80 A/125 A at 400-415 V/440 V/480 V/277 V

BAL9100-0123g-EN

www.conductix.com translated document page 3/56

6.9. Grounding.................................................................................................................................................................. 20

7Control Board Hardware and Fault Indication........................................................................................................................... 20

7.1. Track Supply Control Board (for specially trained personnel only)............................................................................ 20

7.1.1. Control Board LED Indication..................................................................................................................................... 21

7.2. Track Supply Display Board ...................................................................................................................................... 21

7.2.1. LED Indication............................................................................................................................................................ 22

7.2.2. Software Version Number .......................................................................................................................................... 24

7.2.3. Modes of Operation.................................................................................................................................................... 24

7.2.4. Setting Language, Time and Date.............................................................................................................................. 25

7.2.5. Warning Messages..................................................................................................................................................... 26

7.2.6. Error Codes................................................................................................................................................................ 26

8Fuses ........................................................................................................................................................................................ 29

9Transport, Packaging and Storage ........................................................................................................................................... 30

9.1. Transport ................................................................................................................................................................... 30

9.1.1. Safety Instructions for Transport ................................................................................................................................ 30

9.1.2. Transport Inspection................................................................................................................................................... 30

9.2. Packaging.................................................................................................................................................................. 31

9.3. Storage of Packages ................................................................................................................................................. 31

10 Installation................................................................................................................................................................................. 32

10.1. Who is allowed to do the Installation? ....................................................................................................................... 32

10.2. General Installation Recommendations..................................................................................................................... 32

10.3. Place and Conditions of Installation .......................................................................................................................... 33

10.4. Electrical Regulations ................................................................................................................................................ 33

10.5. Electrical Connection................................................................................................................................................. 34

10.5.1. Mains Connection (X2)............................................................................................................................................... 34

10.5.2. Configuration of Control Plug (X3) ............................................................................................................................. 35

10.5.3. Connection Track Cable (X1)..................................................................................................................................... 36

10.5.4. Layout of the External Connections (X1, X2, X3, X4, X5).......................................................................................... 37

10.5.5. Wiring of the Track Supply ......................................................................................................................................... 38

11 Warnings and Precautions........................................................................................................................................................ 41

12 Commissioning ......................................................................................................................................................................... 42

12.1. Safety ........................................................................................................................................................................ 42

12.2. System Conditions..................................................................................................................................................... 43