Operating Instructions

Four indent crimping tool SelectorCrimp

Rev.: 2017-03-03 4 / 7

EN

Icons are used to mark sections of text as described below. Ensure you follow these instruc-

tions and take especial care in such situations. Also provide other users and technicians with

a full set of health and safety instructions!

2 Work steps when crimping

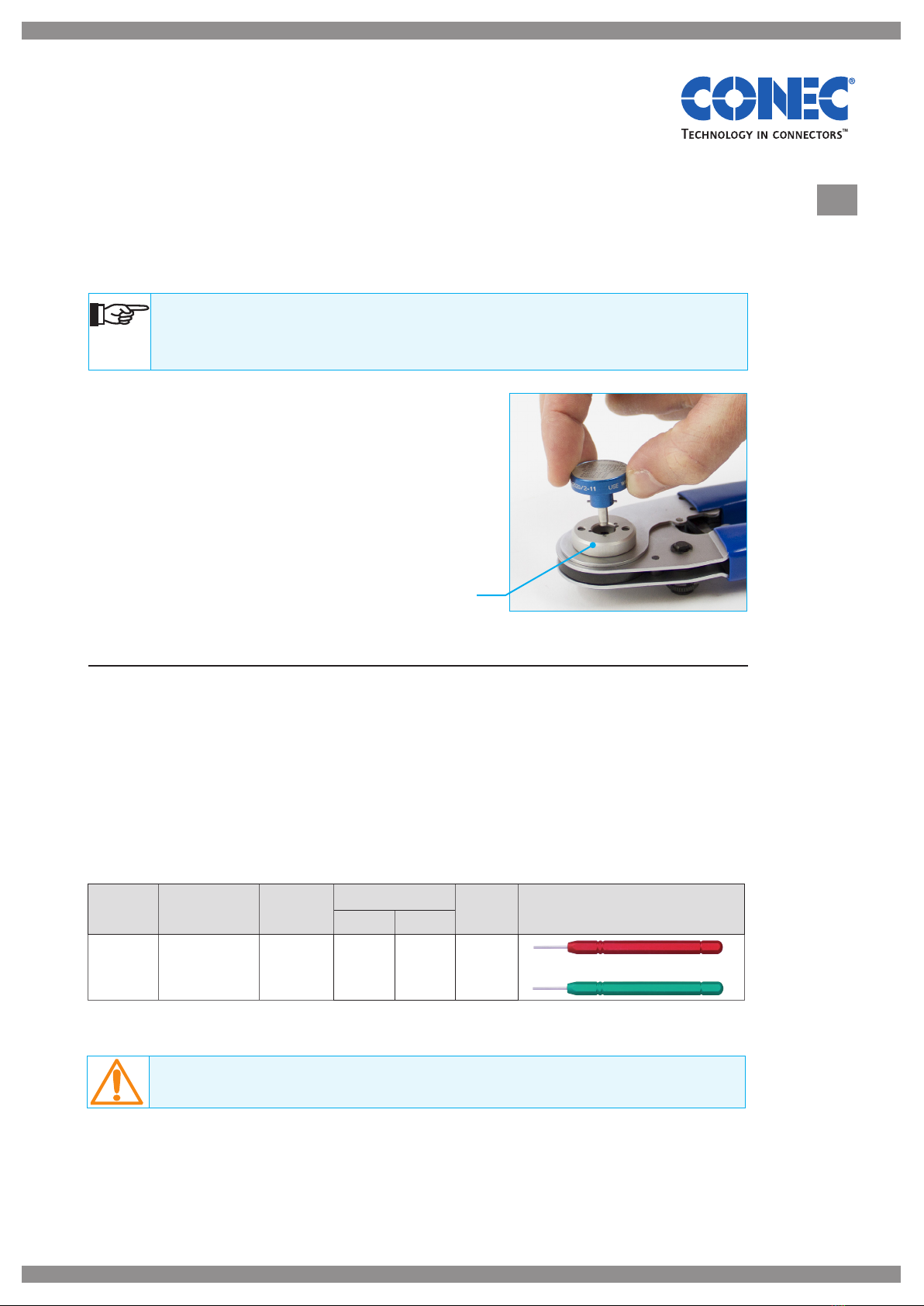

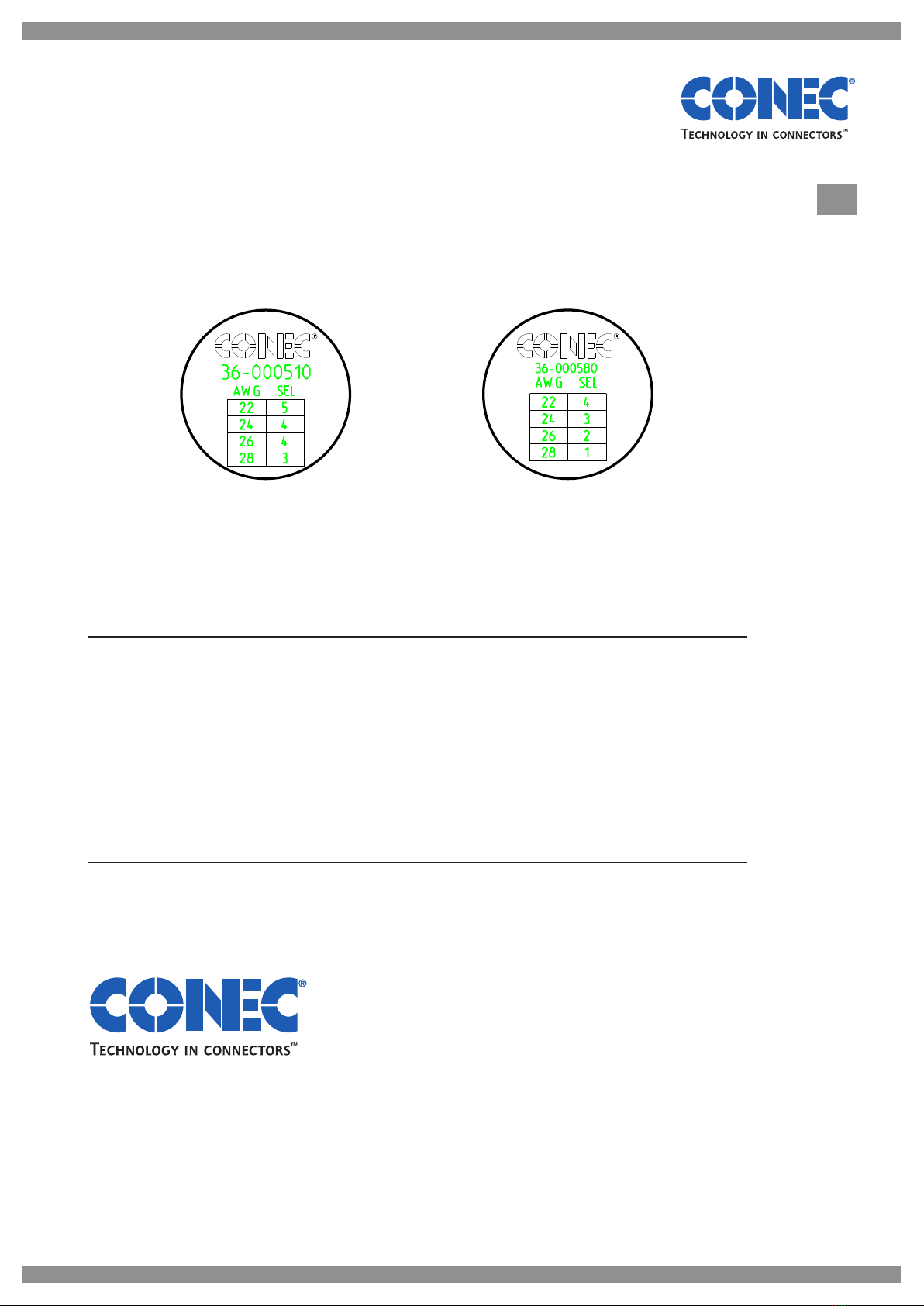

· Decisive for a good quality crimp is the setting of the indenters depending on the contact

cable combination used.

· Set the crimping depth of the indenters with the adjusting disc as described in the section

“Indenter setting”.

· Place the contact in the crimp position up to the stop.

· Insert the stripped cable into the contact in the tool up to the stop and close the tool over

the last ratchet pawl.

· Open the tool.

· Remove the crimped contact from the tool.

Please note!

The information in this section is of particular relevance to the description of a

function or an operating procedure.

WARNING!

This section warns the reader about a potentially dangerous situation that can lead

to death or serious physical injury.

CAUTION!

This section cautions the reader about a potentially dangerous situation that can

lead to minor or moderate physical injury and/or damage to property.

3 Premature opening of the crimping tool (emergency unlocking)

· To release the pawl, lightly press together the shanks of the tool.

· Use a suitable tool (e.g. screwdriver, Allen key etc.) and press the pawl upwards,

asshown in Figure 2.

· Open the tool.