Before beginning installation, read ALL instructions first. Save these instructions

for future use. IF THERE ARE ANY PROBLEMS WITH INSTALLATION OR

OPERATION, DO NOT RETURN TO STORE. PLEASE FIRST CALL CUSTOMER

SERVICE AT 1-877-333-0098 (Monday to Friday, 8:30am to 5:00pm, EST)

INSTALLATION

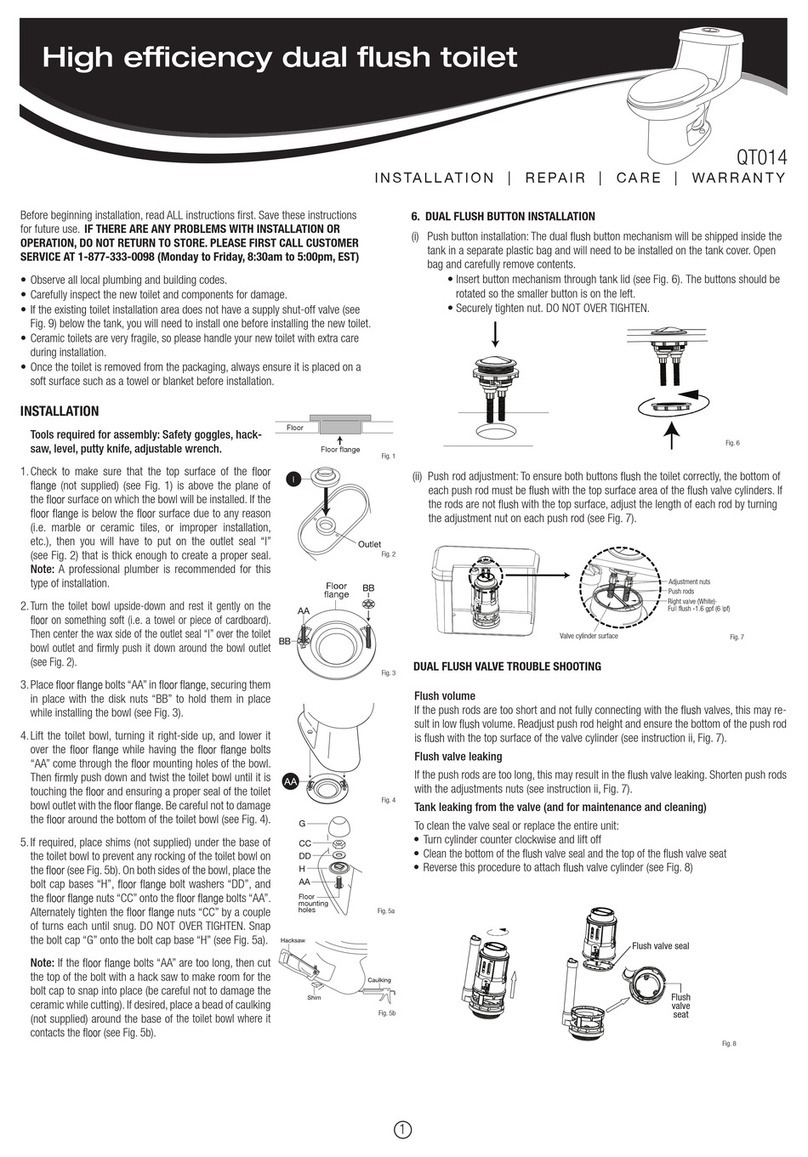

Floor flange

Floor

Fig. 1

Fig. 2

Floor

flange

Fig. 3

Fig. 4

Fig. 5b

Floor

mounting

holes Fig. 5a

Fig. 6

Valve cylinder surface Fig. 7

1

K

Flush

Valve

Threads

Flush Valve Nut Fig. 5c

GG

HH

II

JJ

KK

Fig. 5d

INS T ALL A T I O N

R E P A I R

C A R E

W A R R ANT Y

QT016

Brenna

High efficiency dual flush toilet

• Observe all local plumbing and building codes.

• Carefully inspect the new toilet and components for damage.

• If the existing toilet installation area does not have a supply shut-off valve (see

Fig. 9) below the tank, you will need to install one before installing the new toilet.

• Ceramic toilets are very fragile, so please handle your new toilet with extra care

during installation.

• Once the toilet is removed from the packaging, always ensure it is placed on a

soft surface such as a towel or blanket before installation.

Tools required for assembly: safety goggles, hacksaw,

level, putty knife, adjustable wrench.

1. Check to make sure that the top surface of the floor

flange (see Fig. 1) is above the plane of the floor surface

on which the bowl will be installed. If the floor flange is

below the floor surface due to any reason (i.e. marble or

ceramic tiles, or improper installation, etc.), then you will

have to put on the outlet seal “I” (see Fig. 2) that is thick

enough to create a proper seal.

Note: A professional plumber is recommended for this

type of installation.

2. Turn the toilet bowl upside-down and rest it gently on the

floor on something soft (i.e. a towel or piece of

cardboard). Then center the wax side of the outlet seal “I”

over the toilet bowl outlet and firmly push it down around

the bowl outlet (see Fig. 2).

3. Place floor flange bolts “AA” in floor flange, securing

them in place with the disk nuts “BB” to hold them in

place while installing the bowl (see Fig. 3).

4. Lift the toilet bowl, turning it right-side up, and lower it

over the floor flange while having the floor flange bolts

“AA” come through the floor mounting holes of the bowl.

Then firmly push down and twist the toilet bowl until it is

touching the floor and ensuring a proper seal of the toilet

bowl outlet with the floor flange. Be careful not to

damage the floor around the bottom of the toilet bowl

(see Fig. 4).

5. If required, place shims (not supplied) under the base of

the toilet bowl to prevent any rocking of the toilet bowl on

the floor (see Fig. 5b). On both sides of the bowl, place

the bolt cap bases “H”, floor flange bolt washers “DD”,

and the floor flange nuts “CC” onto the floor flange bolts

“AA”. Alternately tighten the floor flange nuts “CC” by a

couple of turns each until snug. DO NOT OVER TIGHTEN.

Snap the bolt cap “G” onto the bolt cap base “H” (see

Fig. 5a).

Note: If the floor flange bolts “AA” are too long, then cut

the top of the bolt with a hacksaw to make room for the

bolt cap to snap into place (be careful not to damage the

ceramic while cutting). If desired, place a bead of

caulking (not supplies) around the base of the toilet bowl

where it contacts the floor (see Fig. 5b).

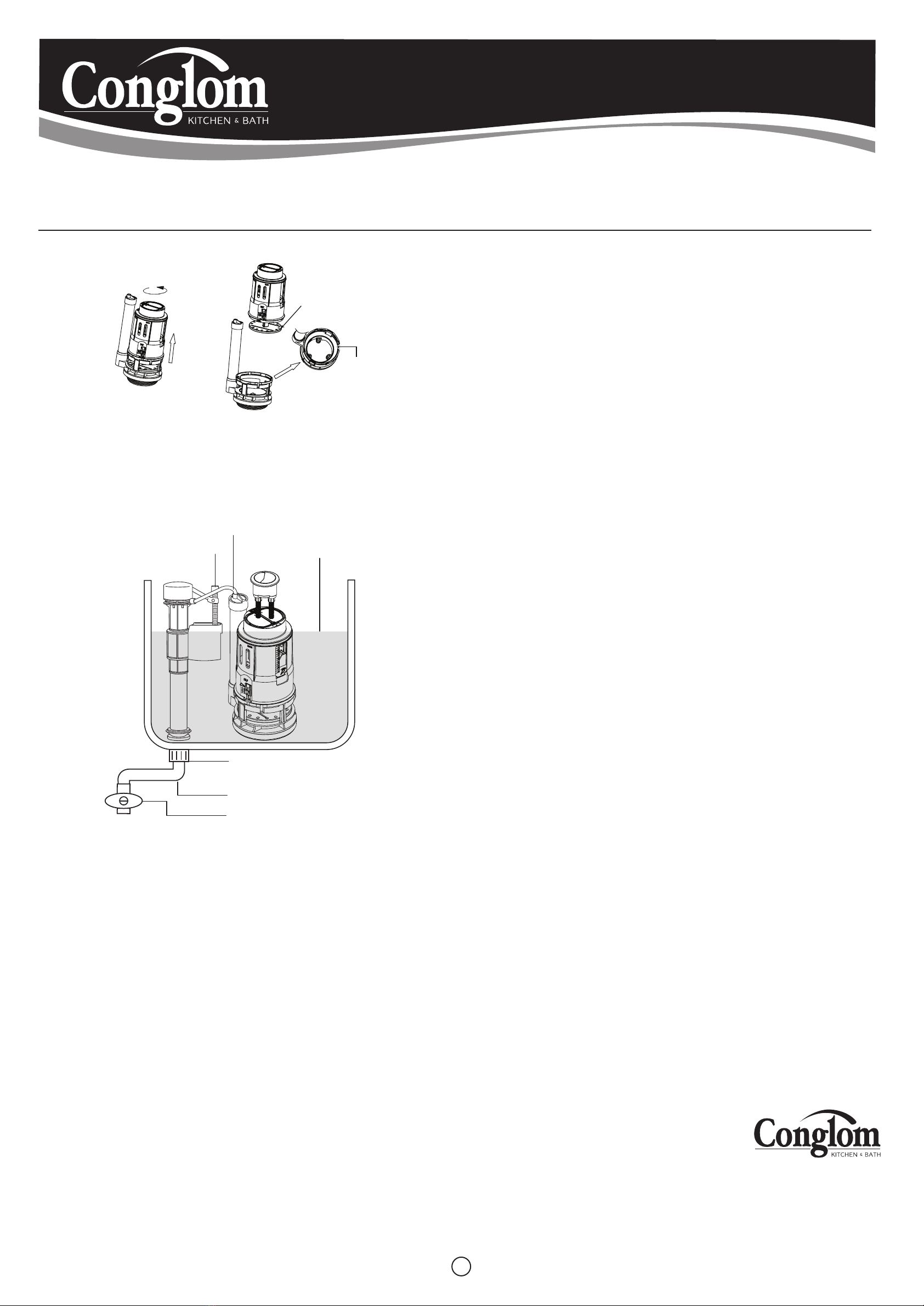

6. Turn the toilet tank upside-down and rest it gently on the

floor on something soft (i.e. a towel or piece of

cardboard). Install the tank gasket “K” over the bottom

threads of the flush valve, making sure that the tank

gasket “K” covers the flush valve nut (see Fig. 5c).

7. Lift the toilet tank, turning it right-side up, and place

the tank onto the back of the top of the toilet bowl,

lining up the 2 tank mounting holes. On both sides of

the tank, install the tank bolts “GG”, inside tank

rubber washers “HH”, outside tank rubber washers

“II”, outside tank metal washers “JJ”, and bolt nuts

“KK”. Tighten bolts alternately by a couple of turns

each, until the ceramic bottom of the tank is just

about to touch the top of the ceramic ribs on the top

of the bowl (note: it may be necessary to push down

on the inside bottom of the tank to make the

tightening easier). DO NOT OVER TIGHTEN (see Fig.

5d).

8. DUAL FLUSH BUTTON INSTALLATION

(i) Push button installation: The dual flush button mechanism will be shipped inside the

tank in a separate plastic bag and will need to be installed on the tank cover. Open

bag and carefully remove contents.

• Insert button mechanism through tank lid (see Fig. 6). The buttons should be

rotated so the smaller button is on the left.

• Securely tighten nut. DO NOT OVER TIGHTEN.

(ii) Push rod adjustment: To ensure both buttons flush the toilet correctly, the bottom of

each push rod must be flush with the top surface area of the flush valve cylinders. If the

rods are not flush with the top surface, adjust the length of each rod by turning the

adjustment nut on each push rod (see Fig. 7).

DUAL FLUSH VALVE TROUBLESHOOTING

Flush volume

If the push rods are too short and not fully connecting with the flush valves, this may

result in low flush volume. Readjust push rod height and ensure the bottom of the push

rod is flush with top surface of the valve cylinder (see instruction ii, Fig. 7).

Flush valve leaking

If the push rods are too long, this may result in the flush valve leaking. Shorten push

rods with the adjustment nuts (see instruction ii, Fig. 7).

Tank leaking from the valve (and for maintenance and cleaning)

To clean the valve seal or replace the entire unit:

• Turn cylinder counter clockwise and lift off

• Clean the bottom of the flush valve seal and the top of the flush valve seat

• Reverse this procedure to attach flush valve cylinder (see Fig. 8)

0025S