ZU25201c_e.doc / Jan-12 Page 3 / 34

Table of Contents

1. Compatibility Hint ........................................................................................................ 4

2. Introduction.................................................................................................................. 5

3. Applicable Encoders and Sensors ................................................................................ 6

4. Terminal Assignment ................................................................................................... 7

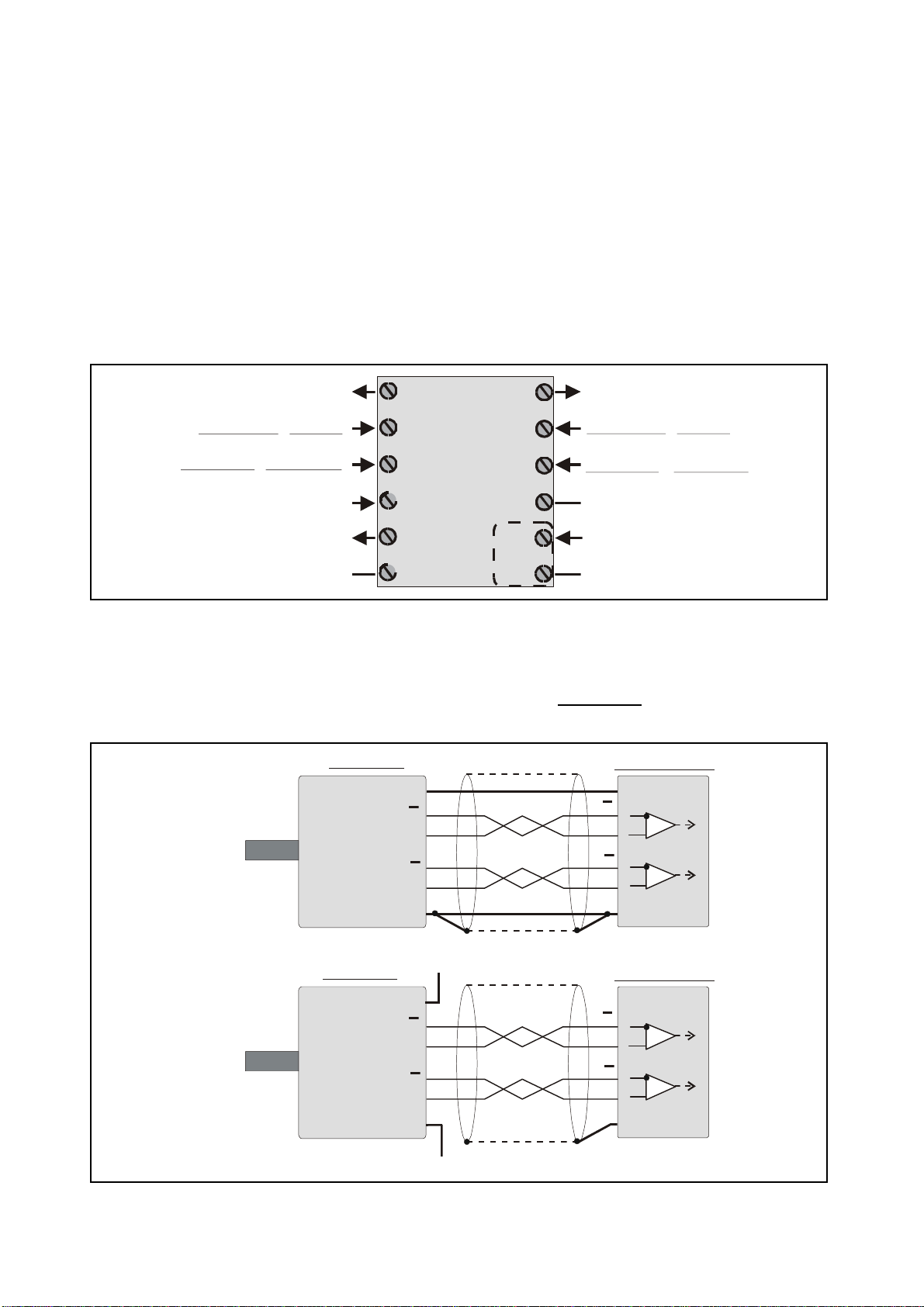

4.1. Incremental encoders TTL / RS 422 ......................................................................7

4.2. Incremental encoder HTL / 12-30V........................................................................8

4.3. Proximity switches, photocells etc........................................................................8

4.4. Control Input..........................................................................................................8

4.5. Analogue outputs ..................................................................................................8

4.6. Serial interfaces ....................................................................................................9

5. DIL Switch Settings.................................................................................................... 10

5.1. Basic mode of operation and power-down memory setting...............................10

5.2. Impulse levels and symmetric / asymmetric input formats ................................11

5.3. Analogue output format ......................................................................................12

5.4. Selecting the RS232 or the RS485 serial interface.............................................13

5.5. Teach function, Test function, loading of default settings .................................13

6. Setup Procedure......................................................................................................... 14

6.1. Operation as single channel counter (without direction signal)

or as positional counter (with direction signal)...................................................15

6.2. Operation as a summing or differential counter with

two independent impulse inputs (A+B, A-B) .......................................................15

7. Readout of the Actual Counter State by Serial Communication................................ 16

8. PC Setup Using the OS3.2 Operator Software............................................................ 17

9. Displays and Softkeys................................................................................................ 18

10. Parameter Settings .................................................................................................... 19

11. Free Programmable Linearization ............................................................................... 25

12. Monitor Functions...................................................................................................... 27

13. Data Readout via Serial Interface .............................................................................. 29

14. Test Functions............................................................................................................ 30

15. Dimensions ................................................................................................................ 31

16. Technical Specifications ............................................................................................ 32

17. Parameter List............................................................................................................ 33

18. Setup Form................................................................................................................. 34