Continental Girbau CG145-55 User manual

Other Continental Girbau Dryer manuals

Continental Girbau

Continental Girbau CG115-25 User manual

Continental Girbau

Continental Girbau L36USS36G User manual

Continental Girbau

Continental Girbau CG75-85 User manual

Continental Girbau

Continental Girbau CG75-85 User manual

Continental Girbau

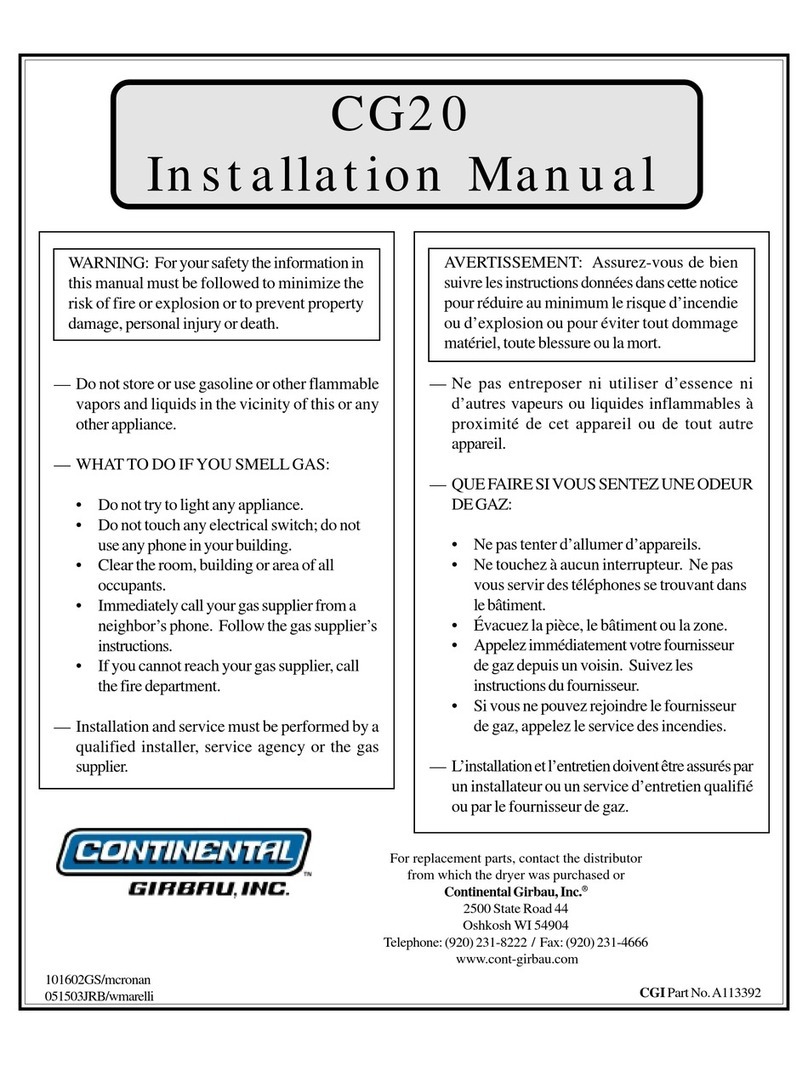

Continental Girbau CG20 User manual

Continental Girbau

Continental Girbau CG50-60 User manual

Continental Girbau

Continental Girbau CG30-40 User manual

Continental Girbau

Continental Girbau CG115-25 III User manual

Continental Girbau

Continental Girbau DL2X30CG Series User manual

Continental Girbau

Continental Girbau L28STK30G User manual

Popular Dryer manuals by other brands

ffuuss

ffuuss eos user manual

KitchenAid

KitchenAid 53-3498 installation instructions

Schulthess

Schulthess Spirit topLine TW 8340 operating instructions

Whirlpool

Whirlpool LGR4624BW0 parts list

World Dryer

World Dryer AirMax D M5-972A manual

Alliance Laundry Systems

Alliance Laundry Systems ADEE9BSS user guide