Continental Girbau CG115-25 III User manual

Other Continental Girbau Dryer manuals

Continental Girbau

Continental Girbau CG75-85 User manual

Continental Girbau

Continental Girbau CG30-40 User manual

Continental Girbau

Continental Girbau CG145-55 User manual

Continental Girbau

Continental Girbau L36USS36G User manual

Continental Girbau

Continental Girbau CG50-60 User manual

Continental Girbau

Continental Girbau L28STK30G User manual

Continental Girbau

Continental Girbau CG75-85 User manual

Continental Girbau

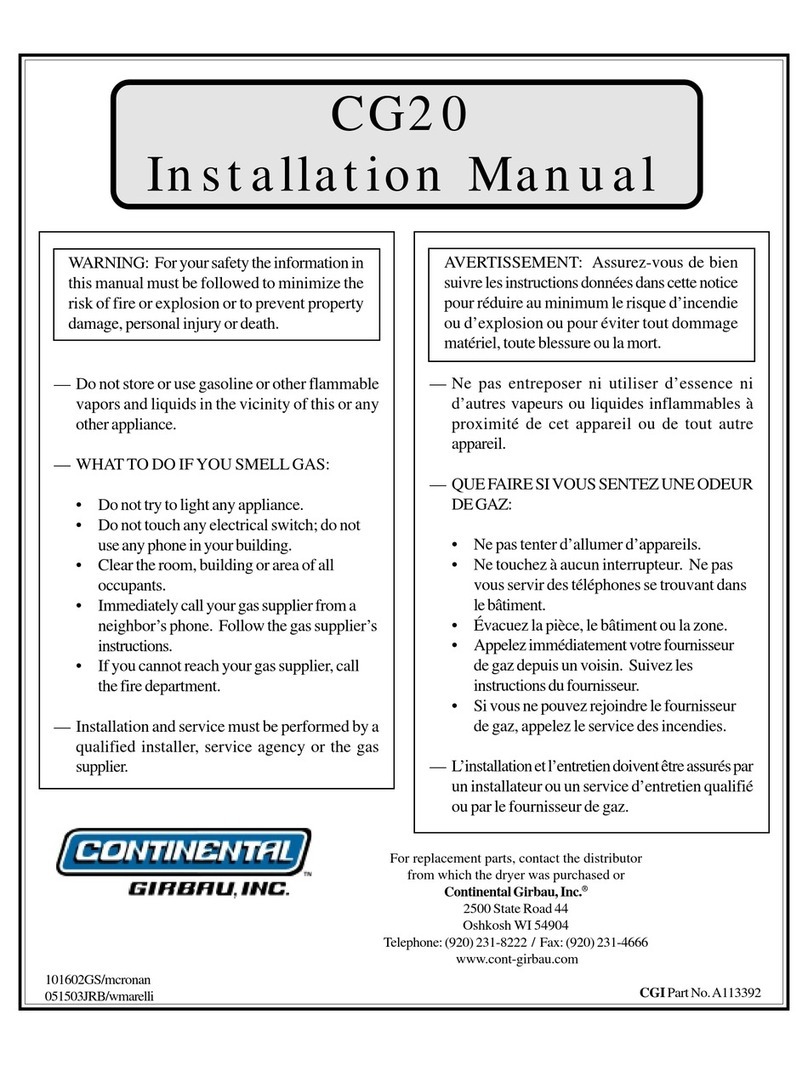

Continental Girbau CG20 User manual

Continental Girbau

Continental Girbau DL2X30CG Series User manual

Continental Girbau

Continental Girbau CG115-25 User manual

Popular Dryer manuals by other brands

ffuuss

ffuuss eos user manual

KitchenAid

KitchenAid 53-3498 installation instructions

Schulthess

Schulthess Spirit topLine TW 8340 operating instructions

Whirlpool

Whirlpool LGR4624BW0 parts list

World Dryer

World Dryer AirMax D M5-972A manual

Alliance Laundry Systems

Alliance Laundry Systems ADEE9BSS user guide