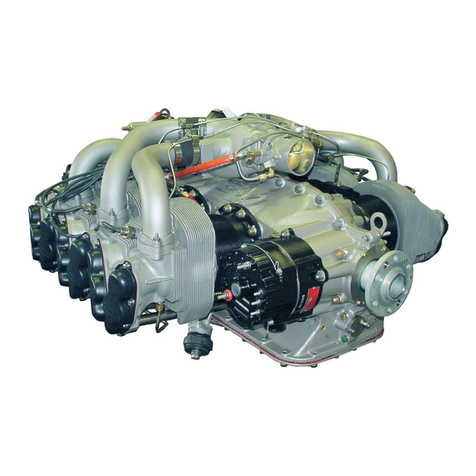

CONTINENTAL MODEL GTSIO-520 ENGINE

INTRODUCTION

The Continental model GTSIO-520-D and

Hare

6-cylinder,

fuel-injected, turbocharged, geared engines rated at 375

HP

at

3400

RPM. These air cooled engines have a wet sump oil system, dual

magnetos and continuous-flow injection system. An exhaust driven

turbocharger provides a full supply

of

intake air

as

the

airplane

climbs away from sea level and enters rarified air

at

altitudes.

Turbocharging provides a means for maintaining take-off power from

sea level

to

altitudes up

to

16,000 feet. The fuel injection system

supplies metered fuel

to

the

individual cylinders through injector

nozzles

to

assure

the

proper fuel-air ratio for desired performance at

all altitudes.

DESIGN FEATURES

1. GENERAL

The engines have overhead valves, air cooled, horizontally opposed

cylinders with 5.25 inch bore, 4.00 inch stroke, 520 cubic inch

displacement, and a compression ratio

of

7.5:1. The cylinders have

down-directed exhaust outlets. The propeller flange has six bolt

holes, two dowel pins and a center pilot extension provided for

attaching

the

propeller. The propeller drive shaft gear

is

driven

by

a

reduction gear, which in

turn

is

driven

by

the

crankshaft through a

splined shaft. Provisions are made in the pilot extension for the

hydraulic propeller control oil which

is

supplied internally from the

governor pad. The crankshaft

is

also equipped with pendulum

type

torsional damper weights. The engines have removable

type

hydraulic

tappets. Positive rotation

is

provided for the exhaust valves

by

the

use

of

rotators. Tappets, push rod ends and rocker arm bearings are

lubricated

by

the engine main oil pressure system.

1