Page 2 of 12

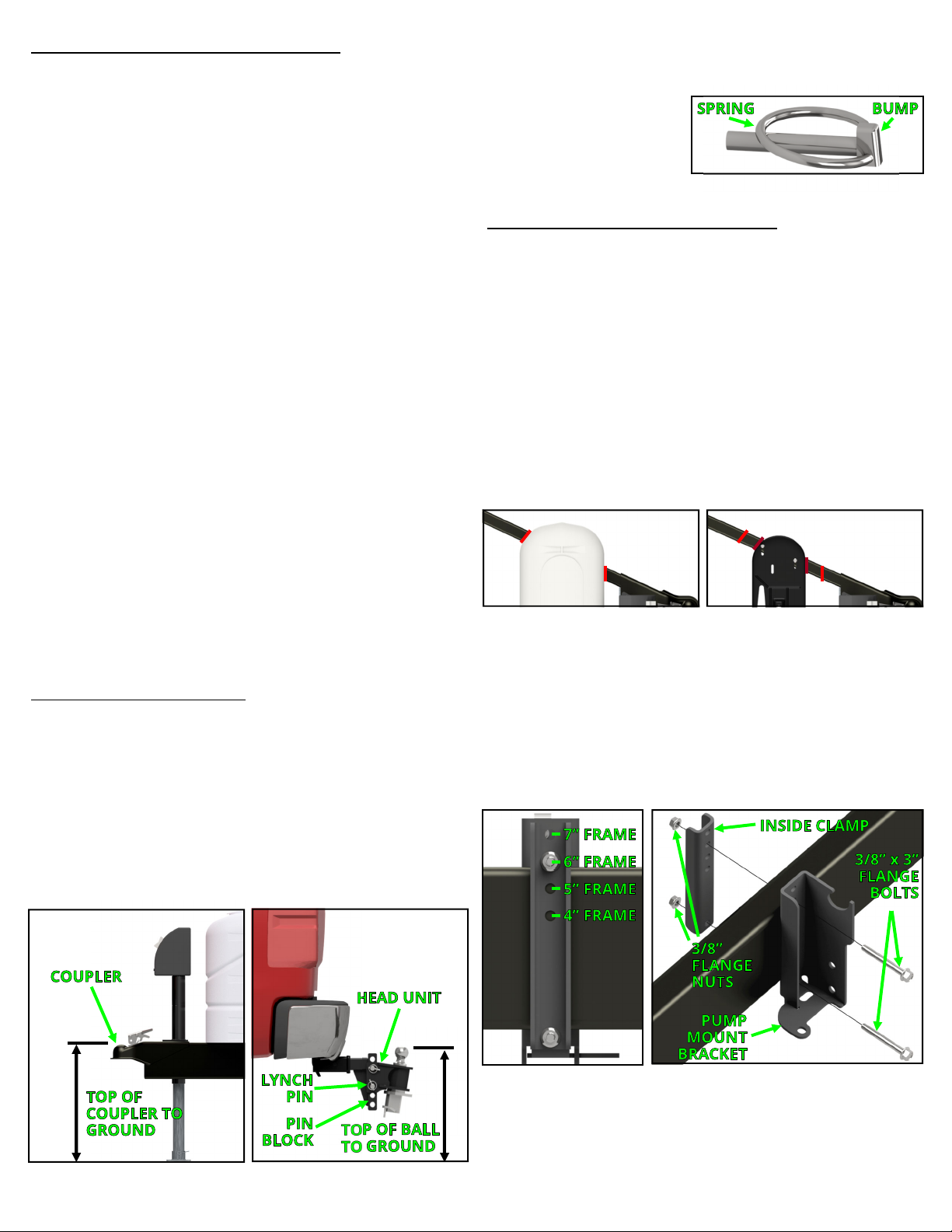

BOX: WDHH4500 & WDHH4502

# DESCRIPTION QTY

1 Head Unit 1

2 3/4” Receiver Pin w/ Cotter 1

BOLT BAG: 4210-200

# DESCRIPTION QTY

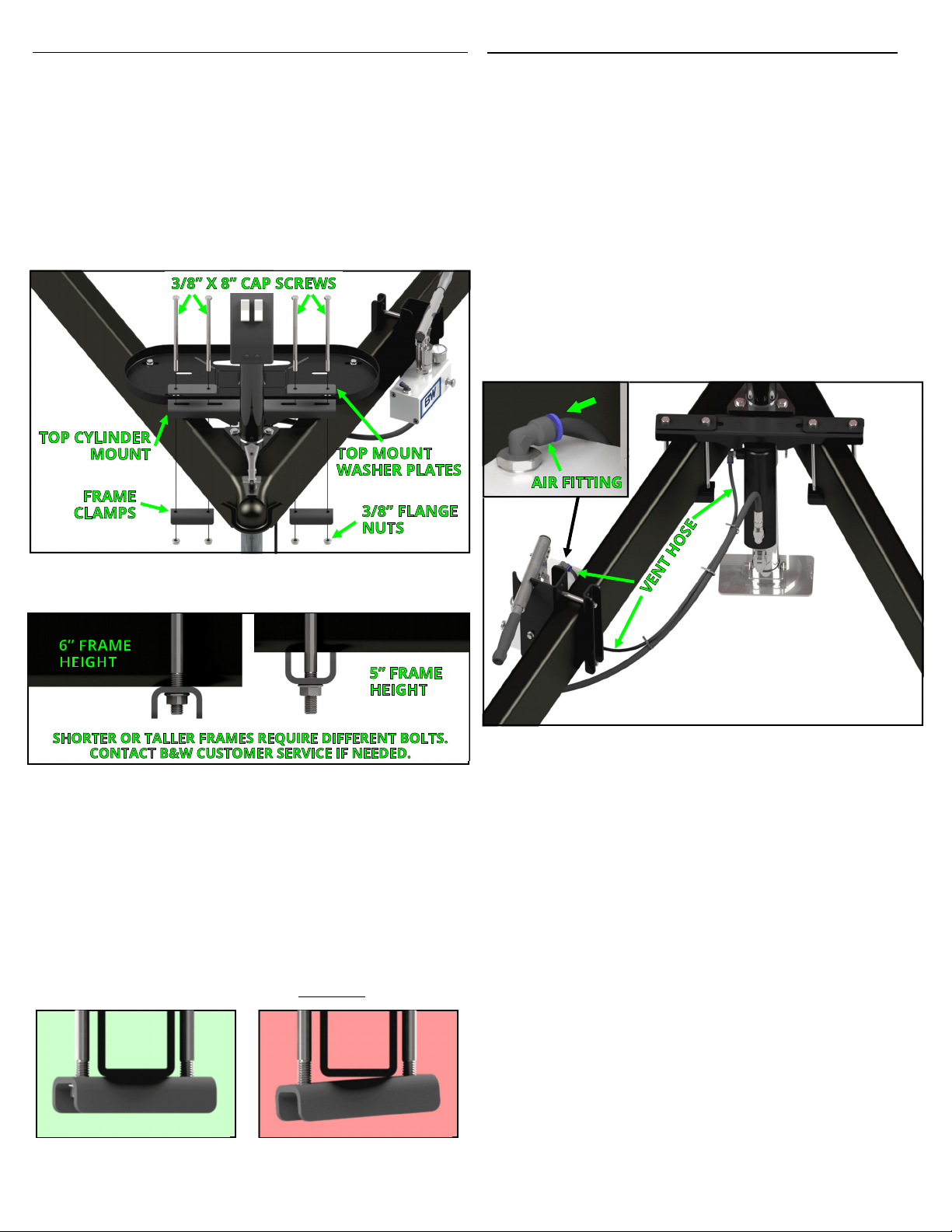

13 2” x 3” x 3/8” U-Bolt 1

14 3/8” x 8” Cap Screw 4

15 3/8” x 3/4” Flange Head Bolt 3

16 3/8” x 3” Flange Head Bolt 2

17 3/8” Flange Nut 8

1

4

3

5

6

10

While installation is being performed, check for signs of

damage or excessive corrosion. Do not install hitch

components over vehicle or trailer parts that are

broken or have compromised structural integrity.

Adding hitch components to the chassis of any vehicle

or trailer can be hazardous. There is potential for

unexpected combustion of fuel, electric shock, burns,

shifting or falling of unstable vehicle, damage to vehicle,

injury from tool usage and many other hazards. This

installation must be completed by someone who is

aware of the hazards involved. This person must be

knowledgeable of proper safety procedures for a

vehicle and trailer modification of this nature, and for

usage of the equipment required to perform the

installation.

Without proper knowledge, towing can be a dangerous

activity. Understand all the risks involved with towing

before proceeding. For information on towing safety,

see "The Trailer Handbook: A Guide to

Understanding Trailer and Towing Safety" from the

National Association of Trailer Manufacturers,

www.NATM.com and your trailer and tow vehicle

manufacturer's owner's manual.

Do not exceed tow or tongue rating of coupler, tow or

tongue rating of hitch, or tow or weight ratings of tow

vehicle or trailer. See vehicle and trailer manufacturer

information for ratings. Exceeding these ratings may

cause damage to towing components or loss of

attachment between the trailer and vehicle.

Do not modify this product in any manner. Doing so

could alter its integrity and lead to a loss of attachment

between the trailer and the tow vehicle.

A visual inspection of the towing components should be

performed before each use. Regularly check that all

connections are secure, including those that secure the

hitch to the vehicle. Check for cracks or damage to the

hitch, tow vehicle receiver, trailer coupler and frame.

Do not use the hitch if cracks or damage outside of

normal wear is found. Using a hitch that has unsecure

connections and/or cracks or damage could result in

damage to the tow vehicle, trailer, towing components

and loss of attachment between the tow vehicle and

trailer.

Failure to comply with the safety information in these

instructions could result in serious injury or death.

IMPORTANT SAFETY NOTICE FOR HITCH INSTALLERS AND CUSTOMERS.

Read all installation and operating instructions along with all labels before installing or using this product. Do not perform

any installation or towing procedures without fully understanding the correct tools and actions for all steps. Call B&W

Trailer Hitches Customer Service Department for support, if needed.

18

Follow all manufacturer instructions and warnings for

tow vehicle and trailer. The Continuum weight

distribution hitch is designed to work with vehicles and

trailers designed to use weight distribution hitches. Do

not use the Continuum hitch with any vehicle or trailer

that is not compatible for use with a weight distribution

hitch.

2

7

Continuum Hitch Components

BOX: WDHL4510* & WDHL4511

# DESCRIPTION QTY

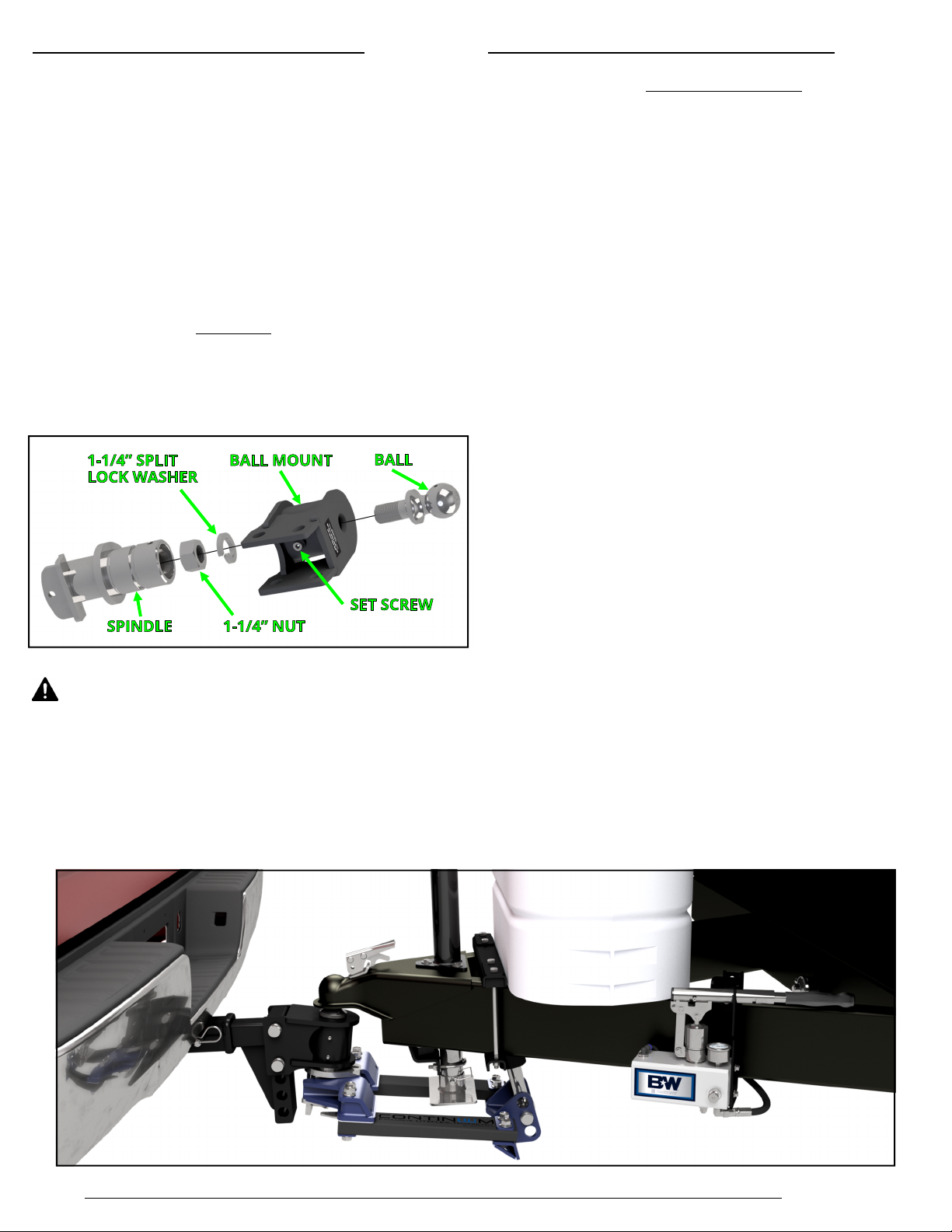

3 Hydraulic Pump & Cylinder 1

4 Load Bar Assembly 1

5 Top Cylinder Mount 1

6 Pump Mount Bracket 1

7 Pump Mount Inside Clamp 1

8 Frame Clamp 2

9 Top Mount Washer Plate 2

10 Fork Holder Bracket 1

11 Top Cylinder Mount Pin 1

12 Cotter Pin 1

8 9

13

17

11

12

14

17

15

17

16

19 20

Extension kit (*not present in

WDHL4510 box)

# DESCRIPTION QTY

18 Hydraulic Cylinder Extension 1

19 3/4” x 4-1/4” Cap Screw 1

20 3/4” Lock Nut 1

Tire condition can influence trailer sway. Never tow

with tires that are under inflated, over loaded, or

damaged. These conditions will greatly lower the speed

at which the trailer will remain stable and may lead to

loss of control. Check tire condition before each tow.