10 CONTRACOR

®

Version 1.3

4.2. Abrasive blasting operations.

ATTENTION!

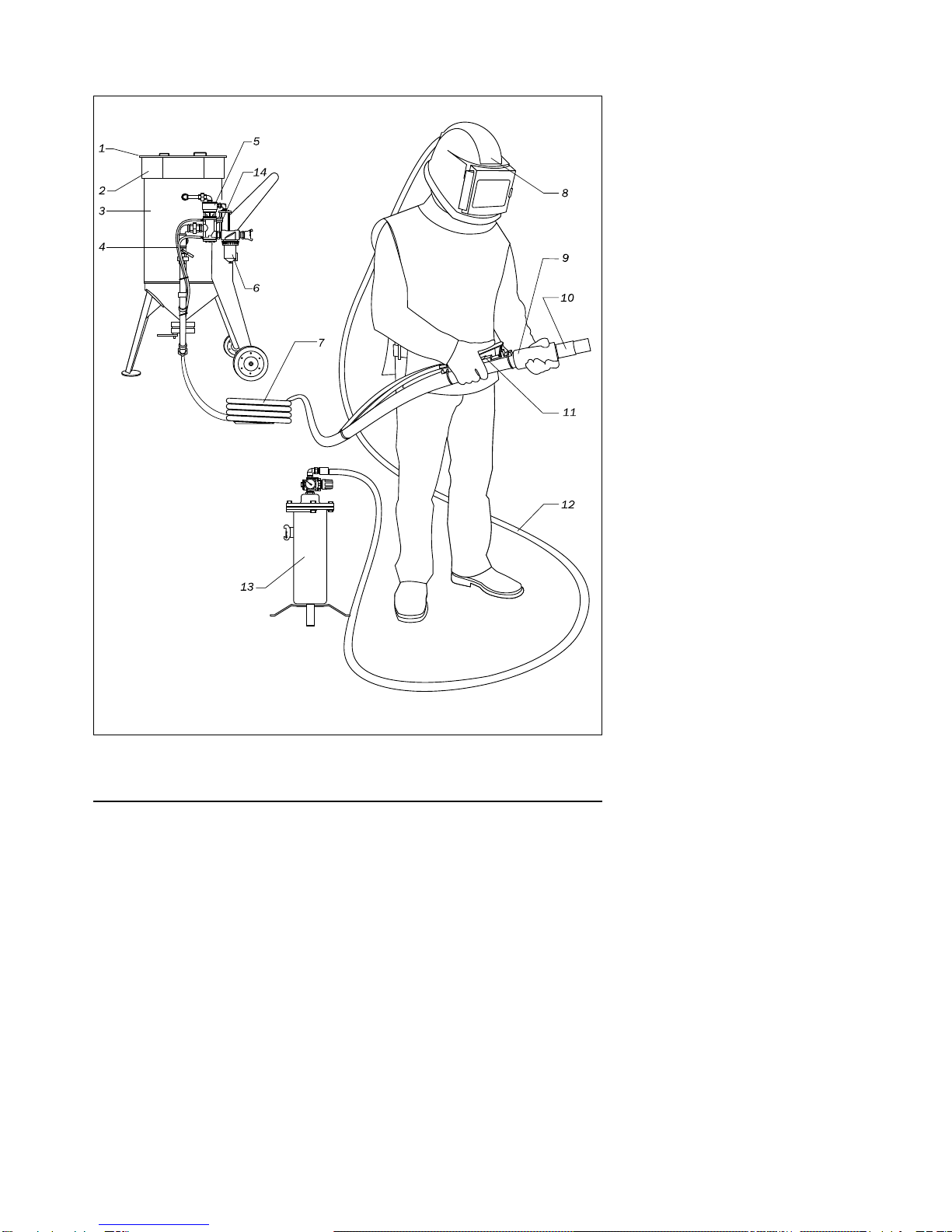

DURINGABREAKINOPERATIONALWAYSOPENSAFETYBALLVALVE14 (Fig.

2.1) ATRCVALVE, OVERAGAINSTTHEBLUELINEOF TWINHOSE(TWINLINE).

RCHANDLELEVERSHOULDBENEVERFIXEDINOPERATIONPOSITION.

SUCHFIXINGMAYCAUSEASERIOUSINJURE.

1. Turn the holder on RChandle and pressthe lever (start up). The tank is pressurized.

Onlycompressed air is expelled from the nozzle.

2. Adjust meteringvalve FSVto provide optimal air-abrasive mixture.The general rule for

abrasive blasting operations: the less abrasive you use, the better.

3. To stop operation you should release the lever (the holder automaticallyreturns to its

initial position).

4.3. Shut-down abrasive blasting operations.

1. Remove the remains of abrasive from the tank. To do this disconnect the nozzle and

point the hose into a suitable container for the abrasive remains. Turn the holder on

the RChandle and press the lever.

2. If upon completion of operation the machine isleft outsideyou should cover it with

plastic Àlm to avoid ingress of moisture into the tank.

ATTENTION!

ATSTARTUP AND SHUTDOWN ALWAYSCHECK FOR PRESENCEOF WATER

INTHEVALVEBYOPENINGUPPERBALLVALVE (Fig. 7.3). IF ALARGE

AMOUNTOFWATERISPRESENT, CHECK THEFILTER CAF-0.