6CONTRACOR®Version 2.5

2.1 Package

Article Model Description, package

10301 DBS-100RC

Abrasive Blasting Machine, 100 L, screen,

1, remote control unit RCV, remote control

handle DMH, abrasive metering valve FSV,

RC hose.

10401 DBS-200RC

Abrasive Blasting Machine, 200l, screen,

1, remote control unit RCV, remote control

handle DMH, abrasive metering valve FSV,

RC hose.

RCV Remote control valve (5, Fig.2.1)

10880 DMH Remote control handle (11, Fig.2.1)

12103 TWINLINE

Remote control twin hose, d=6mm, roll 40 m

(4, Fig.2.1)

3. Set-up, operation and shut-down

3.1 Preparation for operation

For remote control system start up you should follow these instructions:

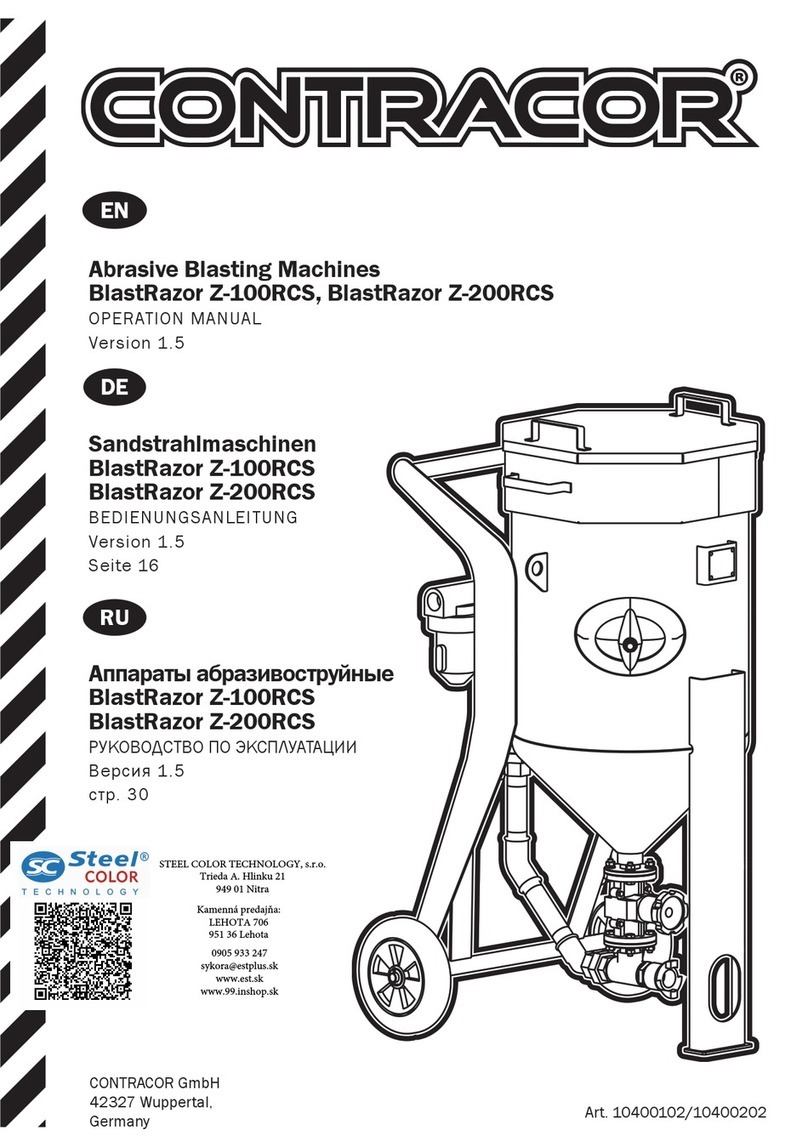

1 — Cover

2 — Screen

3 — Machine tank

4 — RC hose TWINLINE

5 — Remote control unit RCV

6 — Moisture and oil separator CAF-1

8 — Operator helmet COMFORT

9 — Nozzle holder

10 — Nozzle

11 — RC handle DMH

12 — Breathing air hose

14 — Safety ball valve