7

Make sure the compressor has the right capacity to ‘feed’ the chosen nozzle and wanted

blasting pressure.

The compressed air consumption of the machine is determined by the blasting pressure and

the used nozzle orifice diameter:

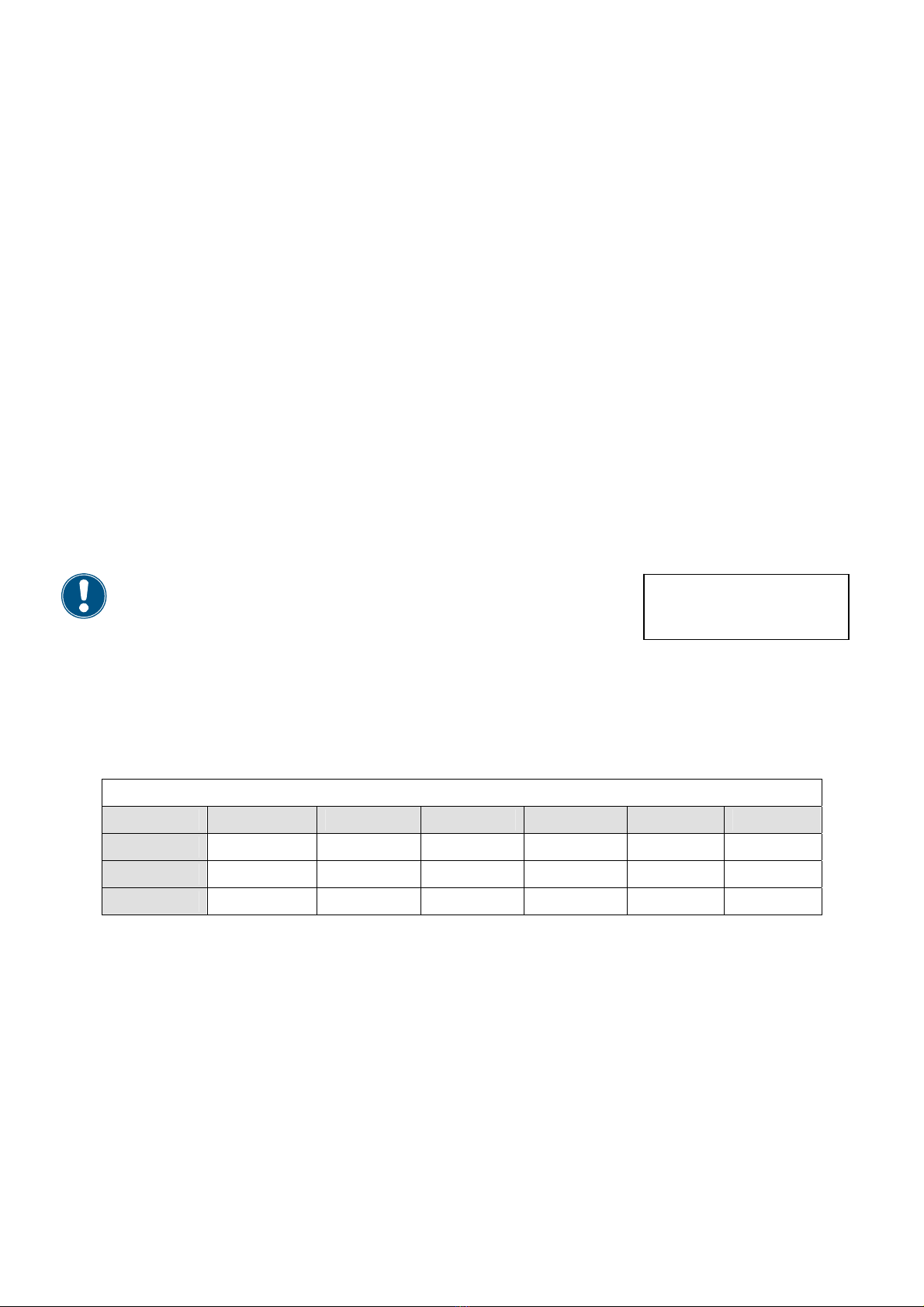

Compressed air consumption in m³/minute

Diameter Blasting pressure in bar

mm 2 3 4 5 6 7 8 9 10

3 0,08 0,25 0,33 0,42 0,50 0,58 0,66 0,75 0,83

4 0,30 0,44 0,59 0,74 0,89 1,03 1,18 1,33 1,48

5 0,46 0,69 0,92 1,15 1,38 1,62 1,85 2,08 2,31

6 0,66 1,00 1,33 1,66 1,99 2,33 2,66 2,99 3,32

7 0,90 1,36 1,81 2,26 2,71 3,17 3,62 4,07 4,52

8 1,18 1,77 2,36 2,95 3,55 4,14 4,73 5,32 5,91

9 1,50 2,24 2,99 3,74 4,49 5,23 5,98 6,73 7,48

10 1,85 2,77 3,69 4,62 5,54 6,46 7,39 8,31 9,23

11 2,23 3,35 4,47 5,59 6,70 7,82 8,94 10,05 11,17

12 2,66 3,99 5,32 6,65 7,98 9,31 10,64 11,96 13,29

13 3,12 4,68 6,24 7,80 9,36 10,92 12,48 14,04 15,60

For data on other nozzles or pressures please contact your supplier or the manufacturer.

Theory:

The pot of the machine is filled with blasting media and then pressurised. When the machine

is started an air flow with the same pressure starts flowing underneath the pot through the

blast hose to the nozzle Because pot pressure and transportation air pressure are the same, the

blasting media can fall freely inside the transportation air and is directed onto the surface.