10 CONTRACOR® Version 2.0

ENGLISH

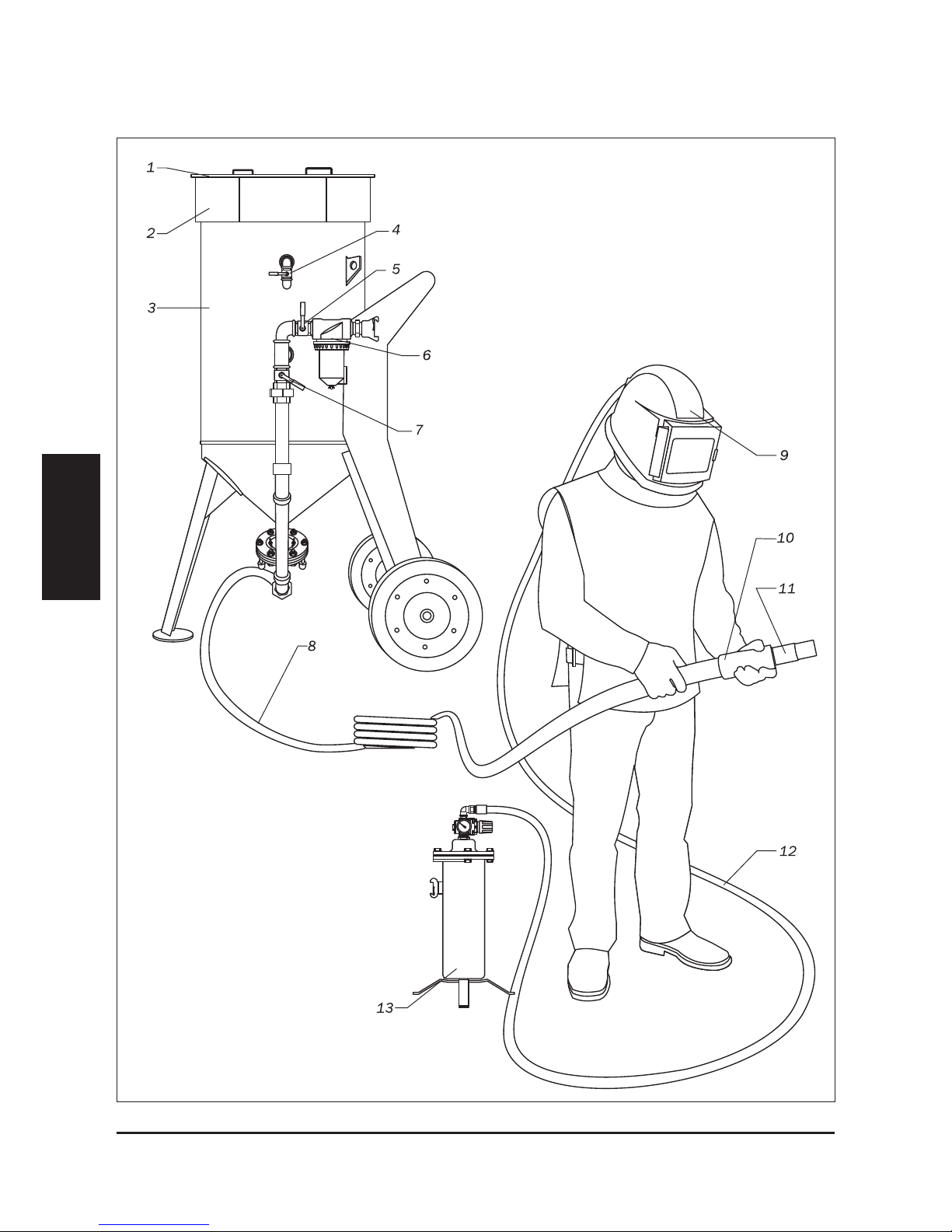

5. General Drawing.

No Order

No Description Q-ty

DBS-100 DBS-200

1 10900 Hose coupling, CFT 2 2

2 10911 Nipple 1 1/4” (MM), rubberized 4 4

3 10930 Oil-Moisture separator, CAF-3 1 1

5 10915 Union with cap nut, straight, 1 ”, (FM) 2 1

6 10909 Elbow, 90°, 1 ” (FM) 1 1

7 10910 T-piece, 90°, 1 ”, (FFF) 1 1

8 10942 Ball valve, 1 ”, (MM) 2 2

9 10913 Union with a cap nut, straight , 1 ”, (ММ) — 1

10 10914 Pipe 1 1/4” — 1

11 10916 Elbow, 45°, 1 1/4” (ММ) 1 1

12 10917 Pipe 1 1/4” 1 1

13 10919 Elbow, 45°, 1 1/4” (FM) 1 1

14 10990 Y-piece, 45°, 1 1/4”, (FFF), rubberized 1 1

15 10921 Pipe 1 1/4”, (100mm), rubberized 1 1

16 10920 Metering gate valve, FSV 1 1

17 10952 Pipe 1” 1 1

18 10953 Elbow 90°, 1”, (ММ) 1 1

19 10954 Pipe 1” 1 1

20 10955 Guide 1 1

21 10960 Pressurizing valve 1 1

22 10950 Pressurizing valve seat 1 1

23 10932 DBS tank service assembly, kit 1 1

24 10935 Screen 1 —

24 10936 Screen — 1

25 10933 Tank cover 1 —

25 10934 Tank cover — 1

33 10922 Wheel 2 —

33 10923 Wheel — 2

34 10941 Elbow, 90°, 1”, (FM) 2 2

35 10938 Ball valve, 1” (MF) 1 1