NAV00292

Controlmatik ABW d.o.o., Fajfarjeva 15, 1230 Domzale, Slovenia, Europe

Tel. +386 1 7213552, Fax +386 1 7213552, info@controlmatik.eu; web: www.controlmatik-abw.si

2

These instructions generally describe the installation, operation and maintenance of

ControlmatikABW shutdown system. ControlmatikABW d.o.o reserves the right to make any

changes that may not be described herein. For any questions please refer to Controlmatik ABW

d.o.o or your local representative.

TABLE OF CONTENTS

TABLE OF CONTENTS ..............................................................................................................2

• GENERAL INFORMATION ...................................................................................................4

• GENERAL DESCRIPTION ...................................................................................................5

• WARRANTY .........................................................................................................................5

• STANDARD EQUIPMENT ....................................................................................................6

• SPECIFICATIONS ................................................................................................................7

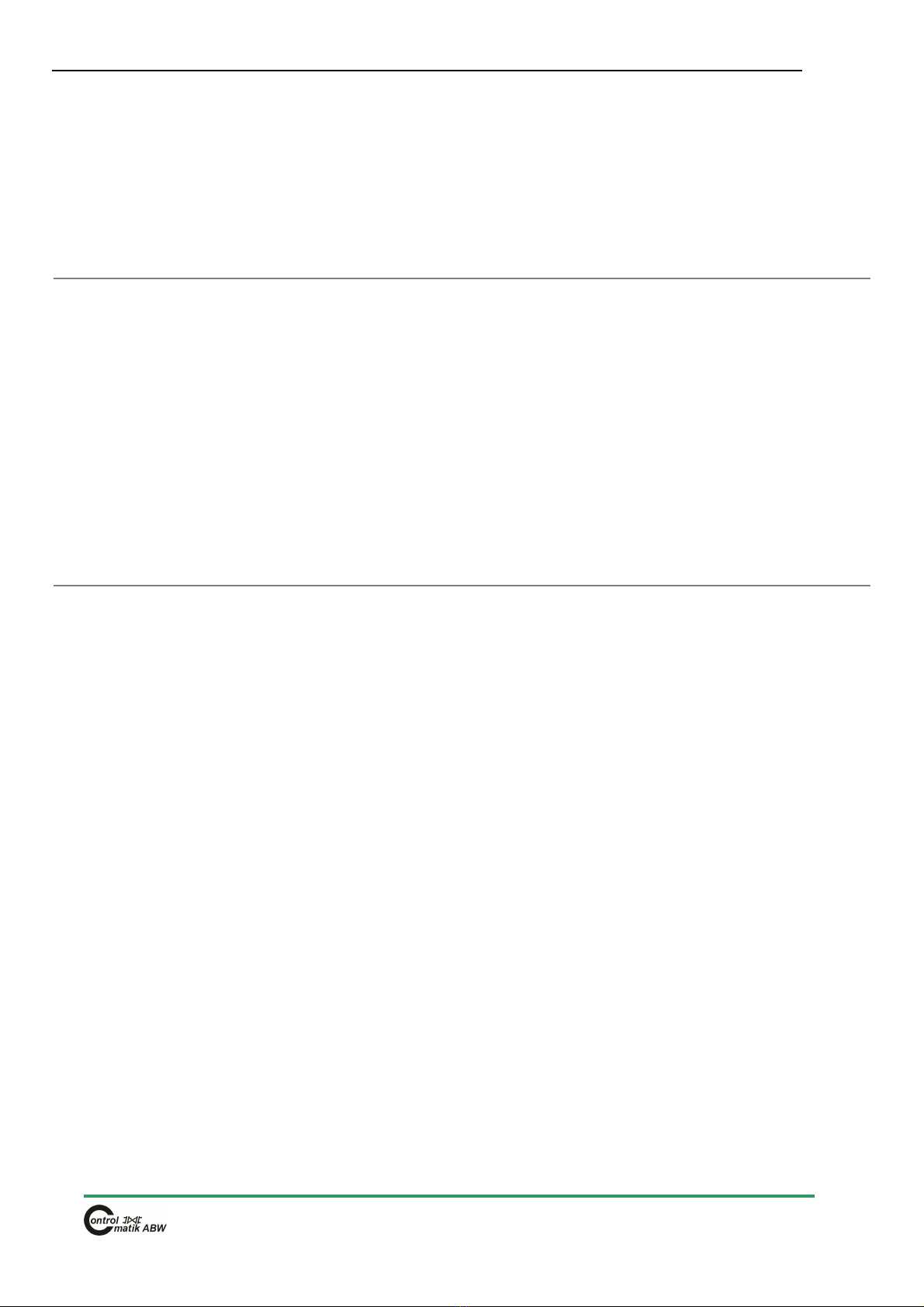

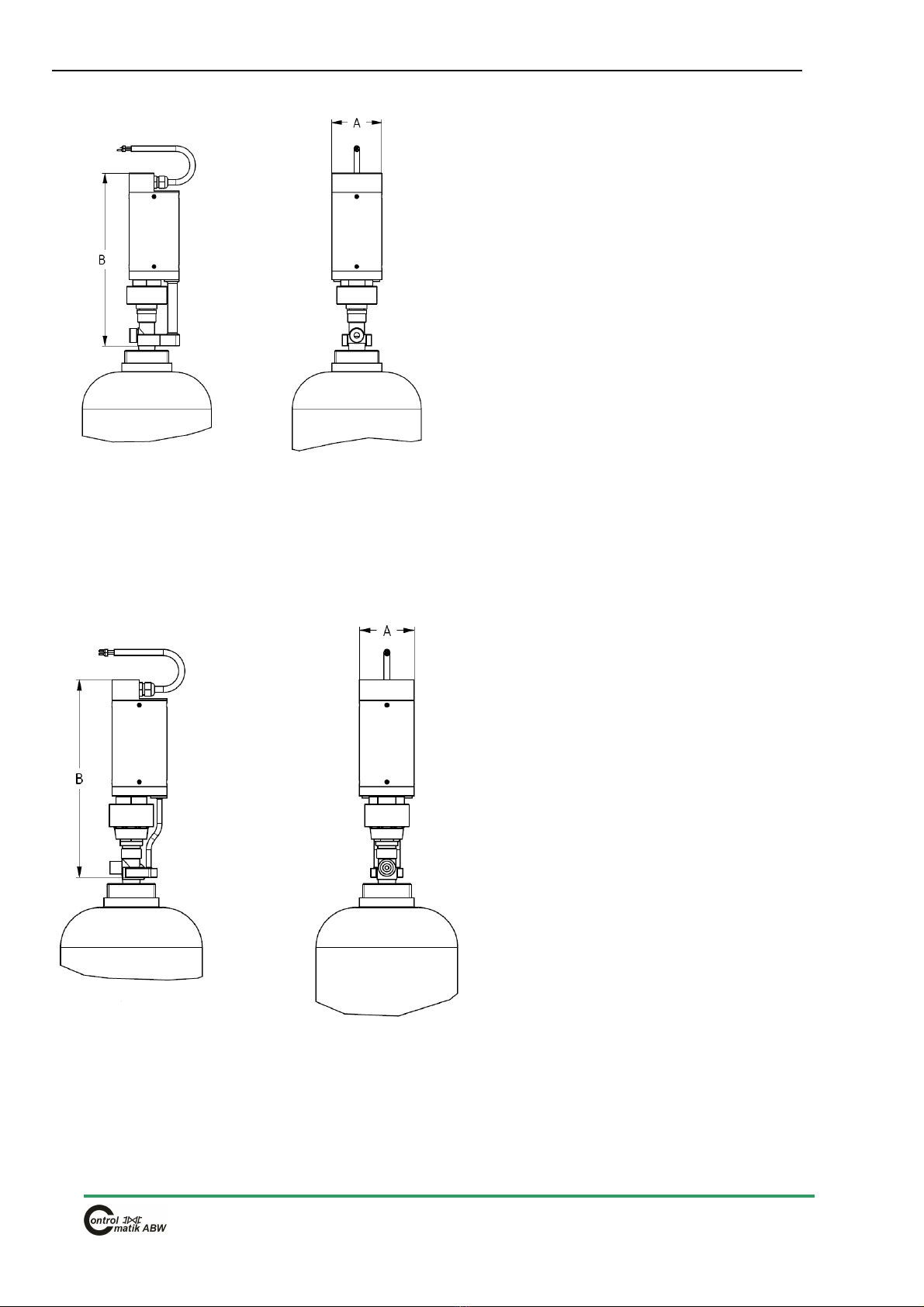

• DIMENSIONS .......................................................................................................................7

• OPERATION.........................................................................................................................9

• INSTALATION ....................................................................................................................10

1. Mounting the M 3800 EPESS-CP control panel on the wall:.......................................................10

2. Mounting the M 3800 EPESS-EA wall bracket: ............................................................................10

3. Flexible cable for electrical actuator ............................................................................................11

• GUIDE FOR MOUNTING SHUTDOWN SYSTEM ON CYLINDER ......................................12

1. Connecting the system and checks .........................................................................................12

2. Mounting the SHUTDOWN to a Cylinder valve ........................................................................13

• START UP THE SYSTEM ..................................................................................................15

MACHINE DRAWINGS, SCHEMES AND DRAWINGS OF CONTROL CIRCUITS ....................16