Form 3000 Issued 15th May 2013

Page 5 of 7

7.2 End of Work Period/Hire Shut-down

Unload the Hoist and raise the hook up to the Upper Travel Limit Switch.

Remove the hand control and the power supply.

Secure the winch/motor against unwanted movement by engaging the Slew Locking Lever on the mounting Yoke.

Clean any dirt or grease from the Hoist.

8. Installation

8.1 Preparation

When installing the Hoist, ensure that:

Read and understand all instructions before installation, particularly Chapter 2 (Safety) and Chapter 5 (Operation).

Ensure that placement of the equipment conforms to the “No Go Zones for plant near overhead powerlines” rules.

The mounting position is firm, stable and capable of withstanding the forces of the Hoist, its load and its operation.

An inspection has been carried out on the equipment before installation, as described in Chapter 2.5 above.

Unauthorised personnel are prevented from entering the mounting area during installation.

Personal safety equipment is worn.

The winch/motor unit is exactly horizontal, to ensure correct wire rope wrapping.

When using the window clamp, ensure the brickwork is of sufficient strength to support the loading imposed and that the

brickwork extends above and over the window opening.

With hollow block brickwork, use load distributing bearers between clamp arms and wall.

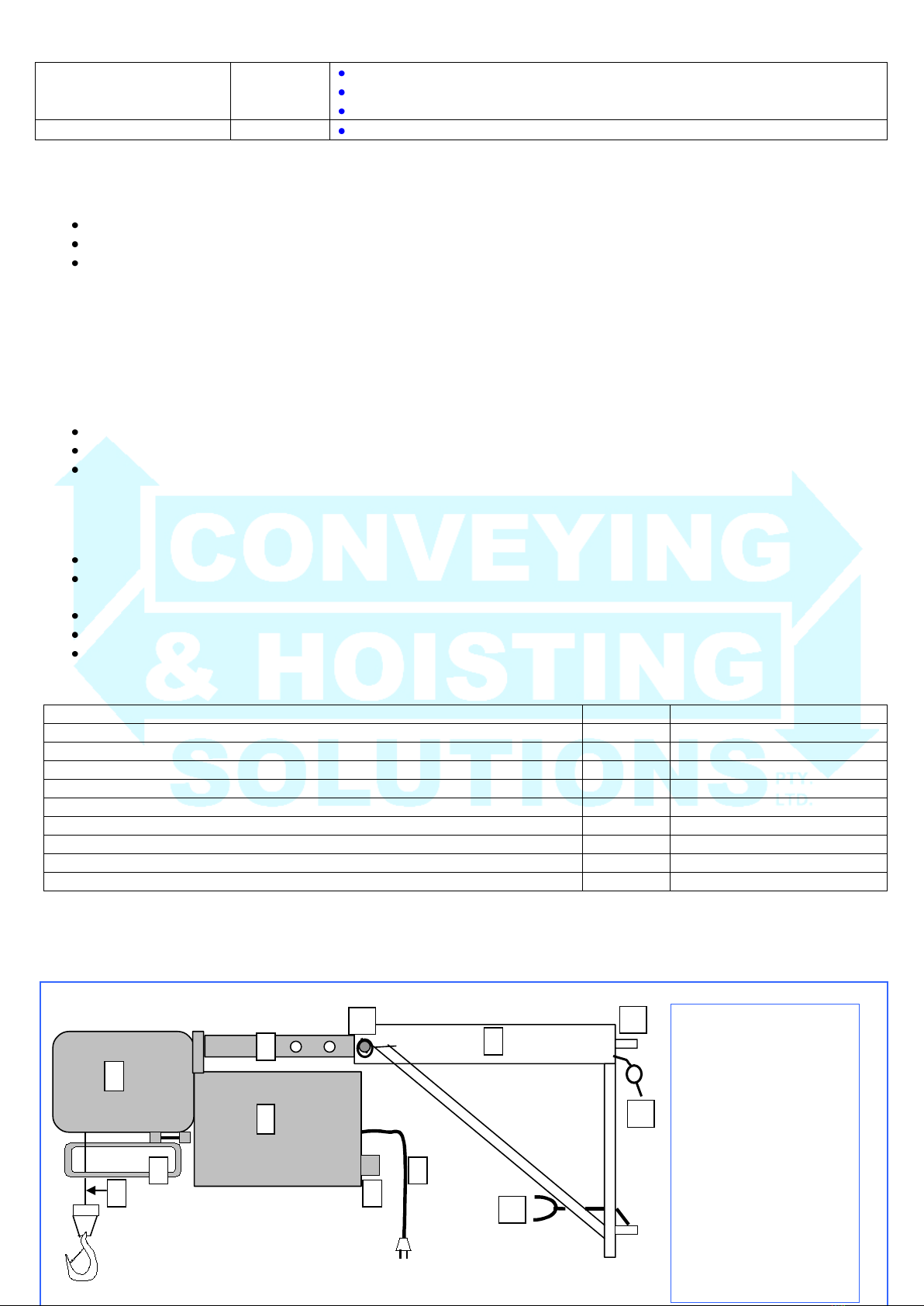

8.2 Scaffold Bracket

1. The scaffold clamp (21) is fastened to the scaffolding

with the scaffold coupling.

2. To prevent falls, fit handrail tubes each screwed to two

vertical frames with 90 degree couplings (32).

3. In addition to the normal scaffold anchorage, anchor

the vertical frame (22), to which the swivel arm hoist

is fastened, at the top and bottom to the building (23)

(anchor tensile and compressive strength, minimum

1.5kN) and brace sufficiently (25).

4. Hang swivel arm and secure with folding cotter pin.

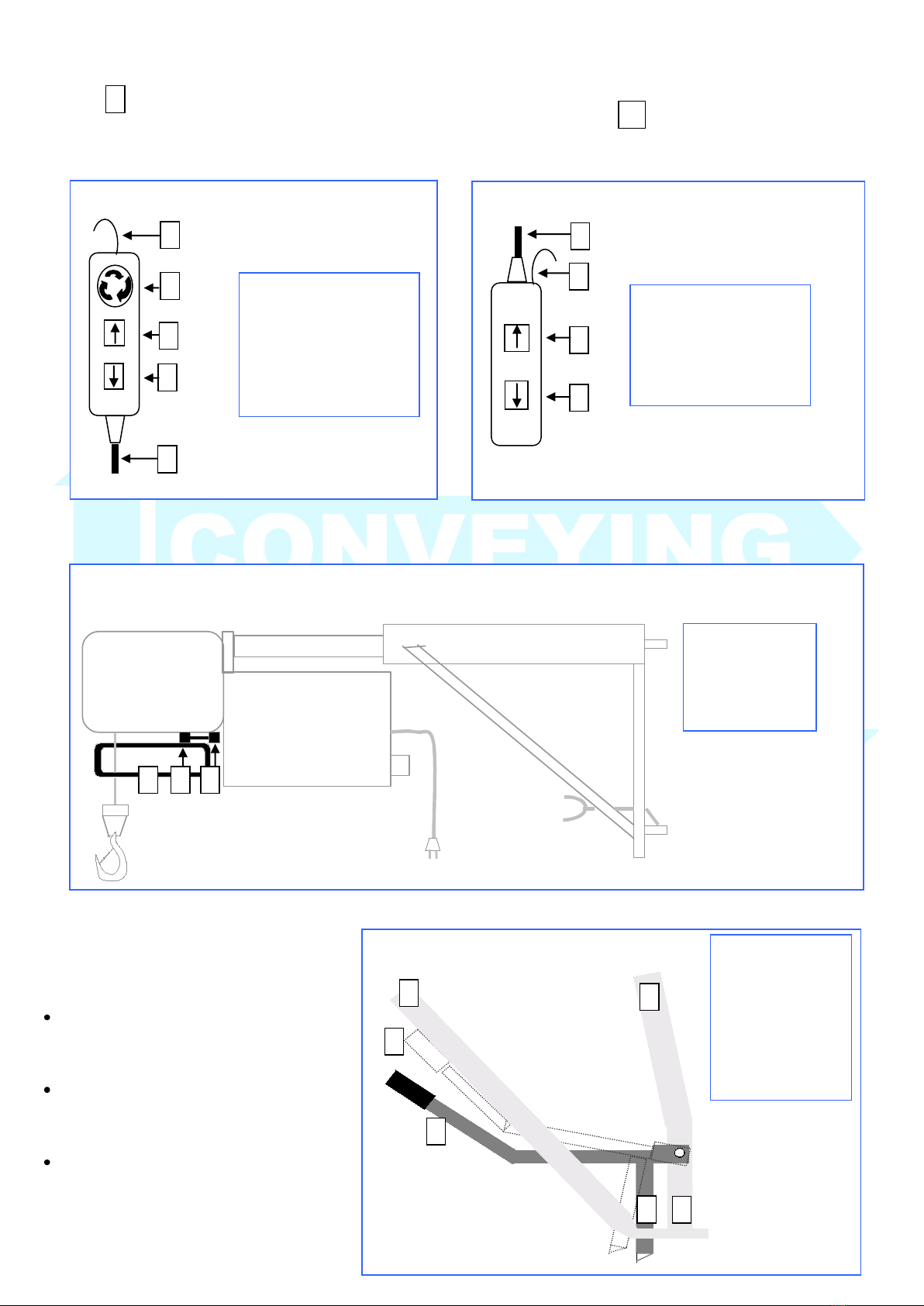

8.3 Counterweight Frame

1. Assemble the tripod away from an edge due to

the danger of a fall during assembly.

2. Lay out both U section rails (16) on level ground

in a triangle.

3. Fit on the ballast box (17) or counterweight frame.

Fit standpipe (18) and struts (19). The standpipe

can be turned 180º on axis according to the

direction the swivel arm is to be swung in.

4. Tighten down strut (19) fixing bolts at both ends.

Tighten standpipe (18) fixing bolt and adjust

Stabiliser (21) so that it rests against the floor.

5. Hang swivel arm hoist and secure with folding

cotter pin.

6. Slide complete tripod with swivel arm hoist and

ballast box or counterweight frame (17) carefully