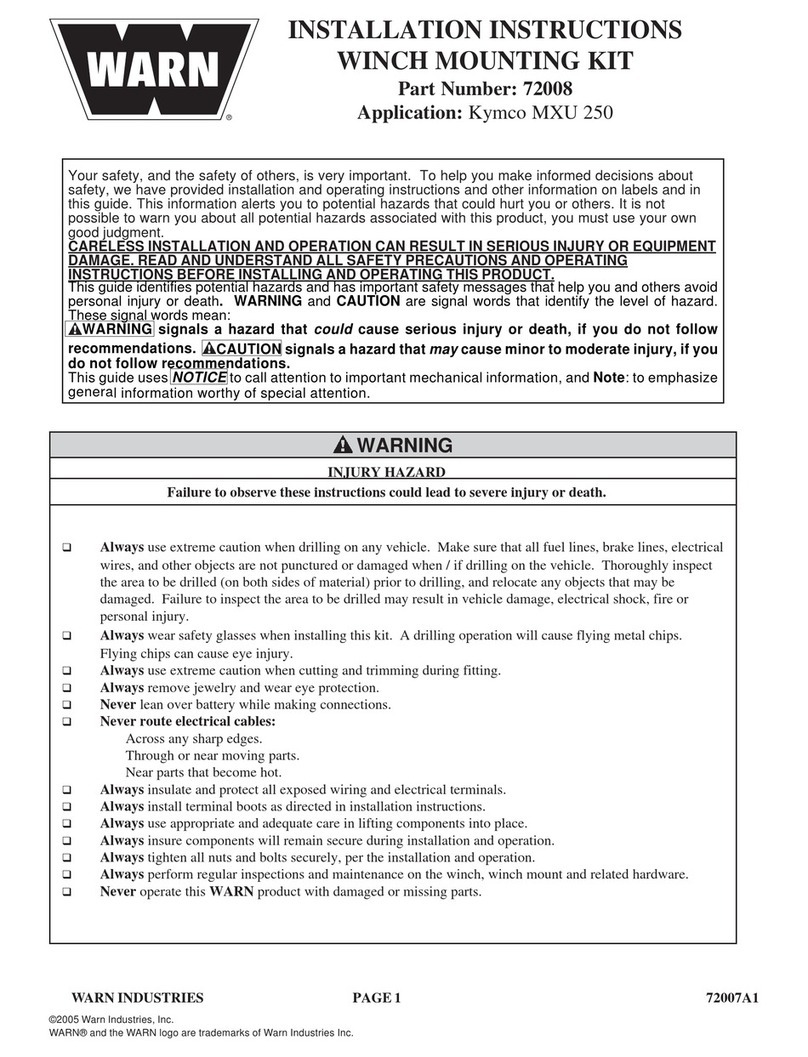

FABRICATION

INSTRUCTIONS

If you choose to fabricate your own mounting plate, follow the

dimensions and tolerances closely. Damage resulting from Improper mounting is

specifically excluded from warranty. Use grade 5 or better fasteners.

3.75

7.50

24.00

8.50

8.40

MIN

4.50

5.75

2.14

C

L

5.00

10.00

C

L

10.00 5.00

1.25

1.88

.62

.44 DIA.

(4 HOLES)

+.02

.00

.50 x 1.00

(2 SLOTS)

ALTERNATE REINFORCING METHODS

ANTI-THEFT PROTECTION

MOUNTING

BRACKET

CUT A SHORT LENGTHOF CHANNEL AND

WELD OVER THE WINCH MOUNTING CAPSCREWS

DO NOT WELD CAPSCREWS

TOLERANCES NOT

SHOWN ±.02

USE 5/16” THICK STEEL

PLATE, MINIMUM

P/N 61949 REV C0

INSTALLATION INSTRUCTIONS

The mounting hole pattern is of critical importance to the strength of your winch. For

winches that are not mounted on a factory mounting plate, it is recommended that

you use a winch mounting bracket as that shown on the last page, applying the

illustrated hole pattern, hole diameters and tolerances.

WINCH MOUNTING

1. The winch is to be mounted with feet forward on a vertical mounting plate. In

this situation the 8" x 1-1/4" fairlead slot must be centered between the lower

holes in the vertical mounting plate. To install: First align the upper holes in

the drum supports with the upper holes in the mounting plate and secure

loosely with two 7/16-14 x 1-1/2 grade 5 hex head capscrews and

lockwashers. The lockwashers must be under the head of all capscrews.

Next Insert two 7/16-14 x 1-1/2 grade 5 hex head capscrews with

lockwashers through the fairlead and lower holes in the vertical mounting

plate and secure loosely in the corresponding holes of the drum supports.

Tighten the above capscrews to 30 lb. ft. (4.14 Kg-m) torque. NOTE: DO

NOT FASTEN FAIRLEAD DIRECTLY TO THE DRUM SUPPORTS.

2. NOTE: Be sure that the drum rotates freely with the clutch disengaged. If the

drum binds or does not rotate freely, the mounting plate is not flat. Place shim

washers between the winch and mounting plate until the drum rotates freely.

3. Place flat washer shims as necessary between the bottom (horizontal) flange of

the mounting plate and the drum support. Insert two 7/16-14 x 1-3/4 hex head

capscrews with lockwashers and flat washers through the mounting plate and

into the threaded holes in the drum supports. Tighten to 30 lb. ft. torque.

CAUTION

NCH IS MOUNTED ON A MOUNTING

SYSTEM RATED FOR SAFE OPERATION AT 15000

LBS. NOT ALL WARN MOUNTING KITS MAY BE

SUITABLE FOR YOUR WINCH. CONTACT WARN

CUSTOMER SERVICE FOR FACTORY MOUNTING KIT

RECOMMENDATIONS.

O THE DRUM SUPPORT BRACKETS

DO NOT USE FASTENERS LONGER THAN THOSE

RECOMMENDED. DO NOT FASTEN FAIRLEAD TO DRUM

SUPPORTS.

DO NOT WELD THE HEAD OF ANY BOLT OR CAPSCREW

used for attaching the winch mounting kit or bumper kit.

Metallurgical changes, after welding, can occur and cause

the fasteners to become brittle and break, even under no-

load conditions. This could result in personal injury or

property damage.