03

PRODUCT APPLICATIONS AND WARNINGS

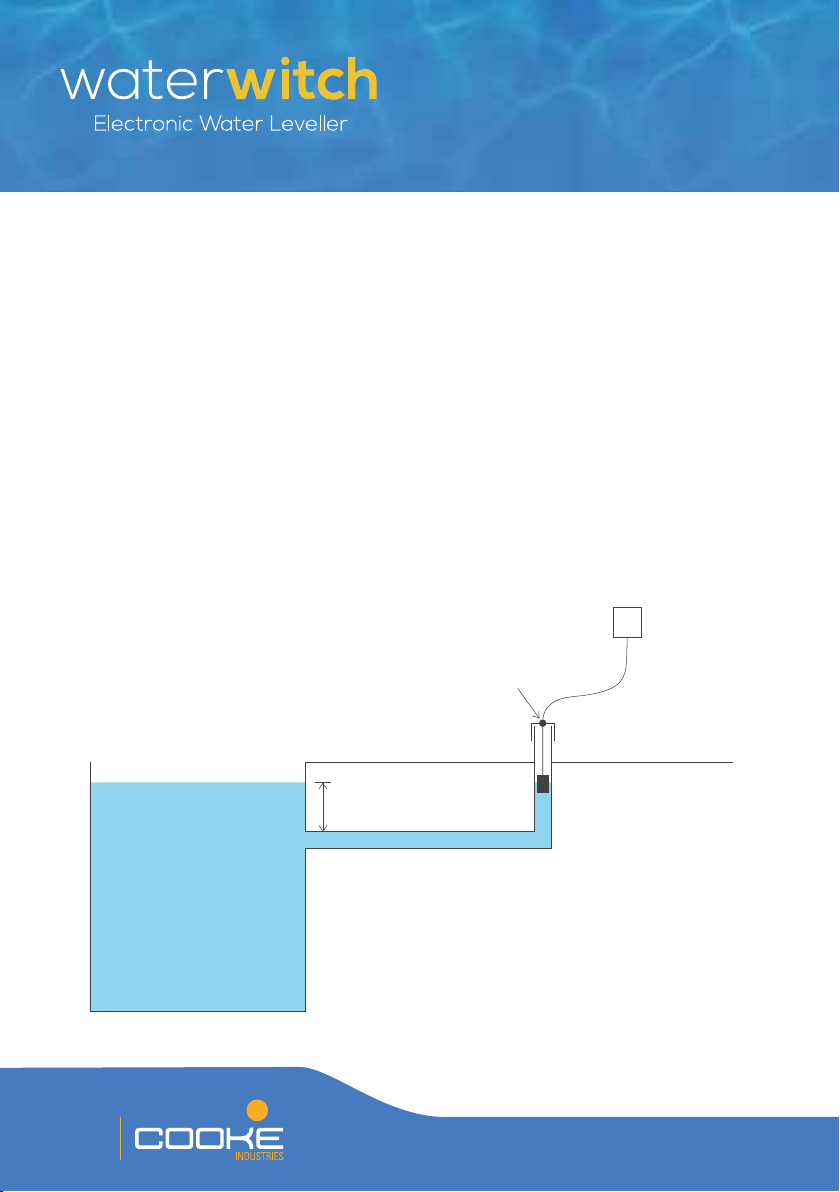

The Water Witch is used in many dierent applicaons and projects to maintain a minimum

water level. Some of the most popular applicaons include:

• Swimming pools and spas •

Balance tanks

• Water features and ponds •

Innity edge troughs

• Water / Splash parks • Commercial pools

• Irrigaon projects • Water tanks

Given the many suitable applicaons for the Water Witch, a quality installaon is required

to ensure performance is not aected by site condions or any other factor.

•

The Water Witch is manufactured

and tested to the highest

internaonal standards. Wear

and onsite condions, however,

may cause component failure. All

installaons must include sucient

overow provisions to ensure a

ooding event does not occur.

• Indoor pools and enclosed projects

must also feature sucient overow

provisions to avoid a potenal

ooding event.

• The Water Witch may not be

suitable for installaons where the

water source is connected to a

pressure pump. Conrm high and

low pressure readings at your site

to ensure the water supply pressure

is always within the unit’s required

operang pressure.

• Contact your local water authority

to conrm whether your proposed

Water Witch supply side installaon

complies with the relevant water

regulaons.

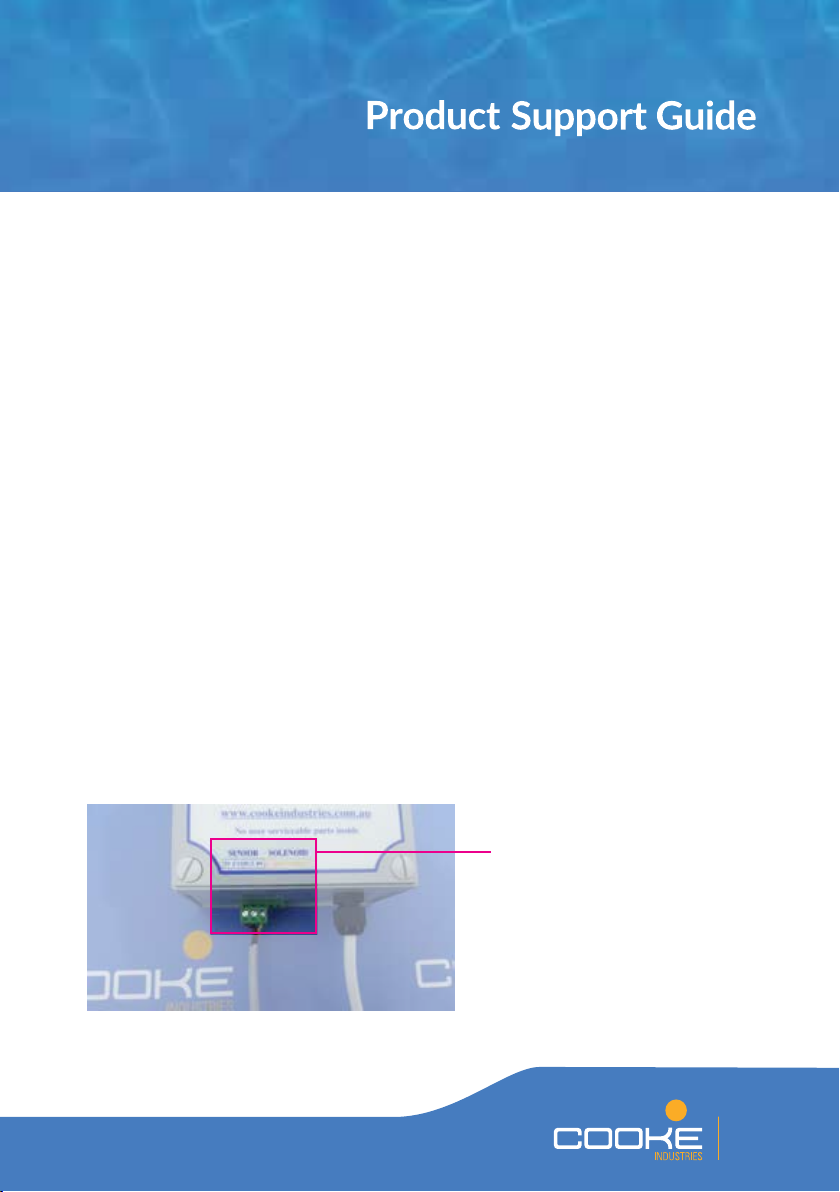

• Individual components may need

to be replaced in the future. All

installaons should incorporate

provisions for easy part replacement.

• The Water Witch includes wearing

components that may fail or be

aected by onsite condions. A

visual inspecon of all components

is required at least every month to

ensure the unit is operang correctly.

•

The power supply must always be

turned o and the Water Witch

power lead removed from the power

supply if the control box cover is

being removed.

Please note the following important project consideraons: