CONTENTS

1.0 INTRODUCTION ..................................................................................1

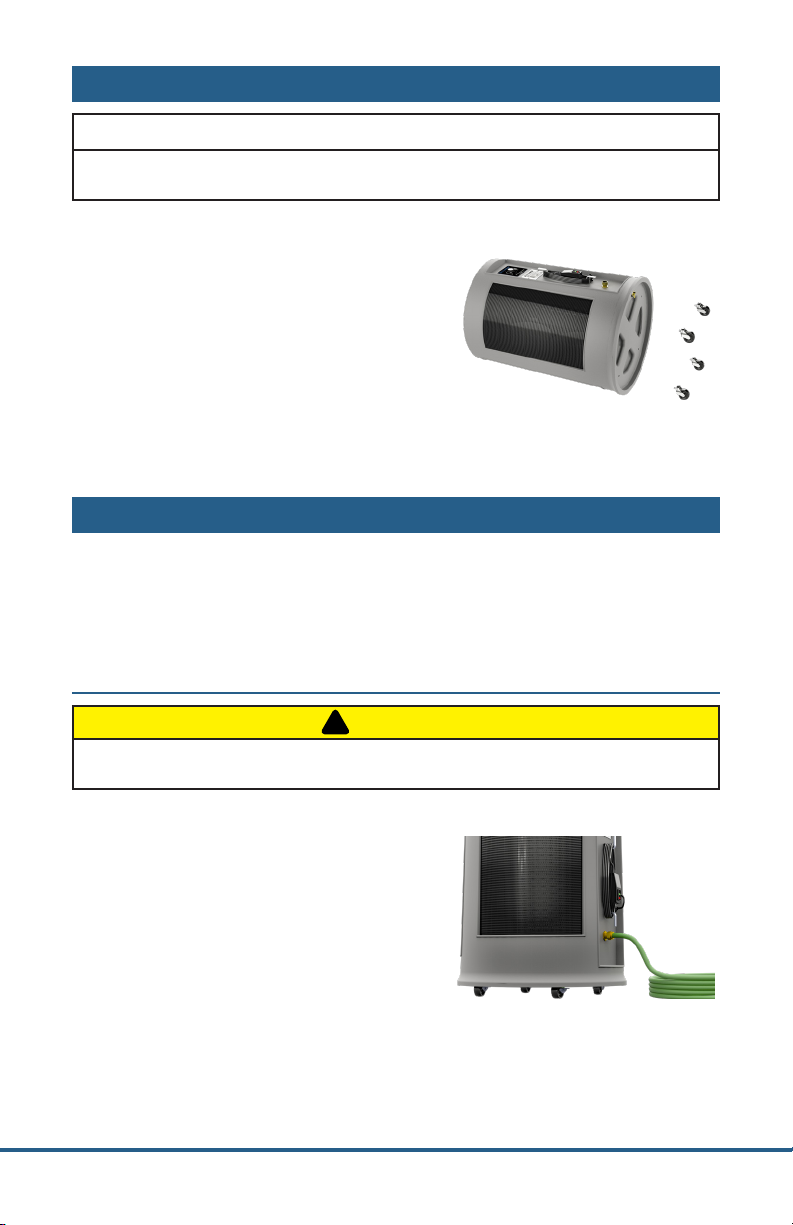

2.0 UNPACKING YOUR FLURRY..............................................................2

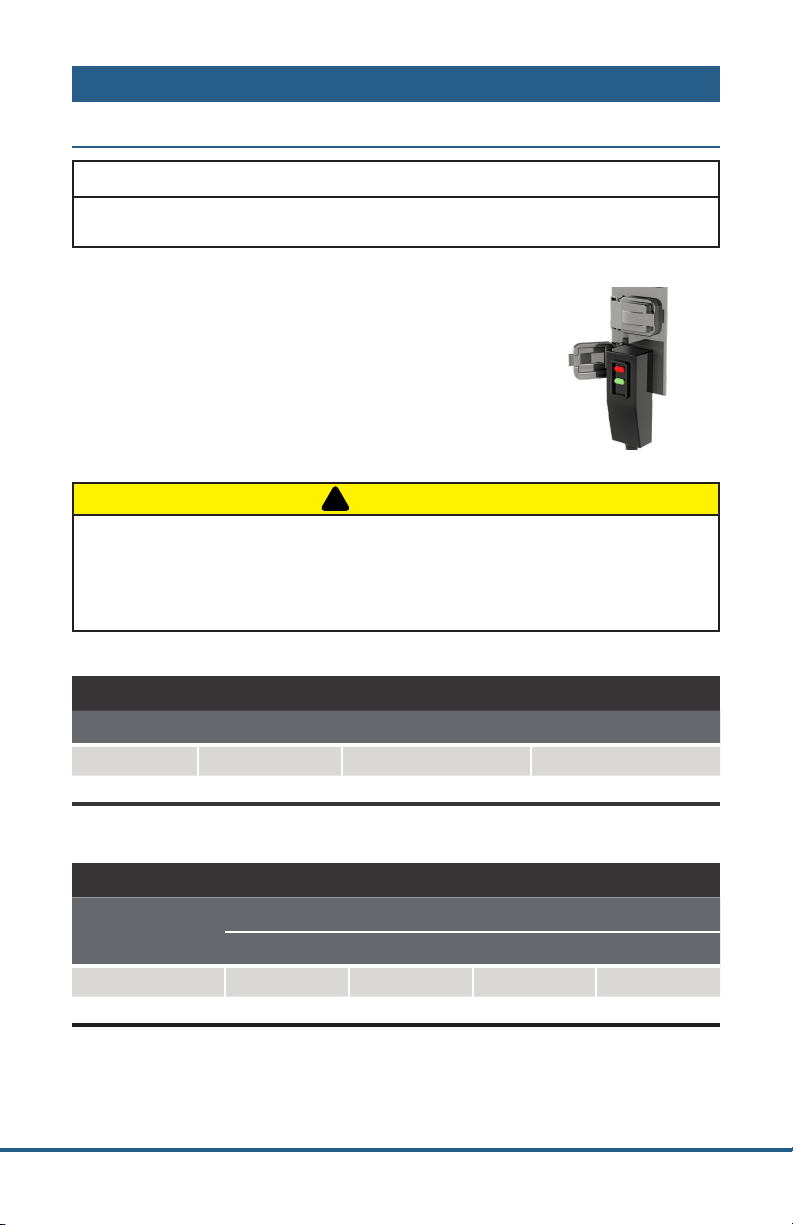

3.0 SETUP OF THE COOLSPACE UNIT .................................................2

3.1 Connecting the water supply............................................................... 2

3.2 Connecting the electrical supply ....................................................... 3

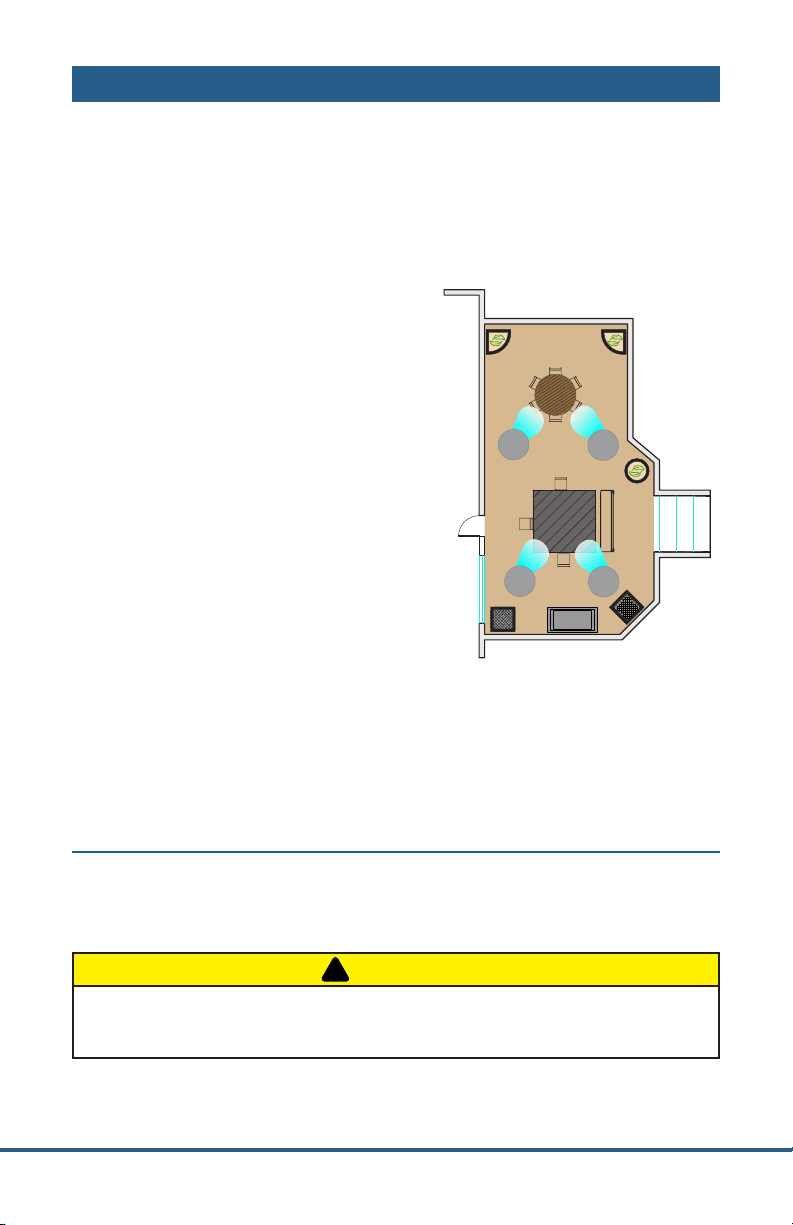

4.0 OPERATING PROCEDURES ...............................................................4

4.1 Filling the unit with water ..................................................................... 4

4.2 Starting the Pump.................................................................................... 5

4.3 Starting the Fan ........................................................................................ 5

5.0 MAINTENANCE AND STORAGE .......................................................6

5.1 Removing the cooling media............................................................... 6

5.2 Daily maintenance................................................................................... 6

5.3 Periodic maintenance............................................................................. 6

5.4 Storage......................................................................................................... 7

6.0 TROUBLESHOOTING/REPAIR...........................................................8

6.1 Troubleshooting ....................................................................................... 8

6.2 Troubleshooting Guides........................................................................ 9

6.3 Fan Repair Procedures.......................................................................... 12

6.4 Pump Repair Procedures..................................................................... 13

6.5 Wiring Diagram....................................................................................... 14

6.6 Technical support .................................................................................. 14

7.0 WARRANTY ........................................................................................15

7.1 Warranty Registration ........................................................................... 15

7.2 Warranty Parts ......................................................................................... 15

7.3 Optional Accessories and Replacement Parts.............................. 15

Due to continuous product innovations, we reserve the right to change

product specication without due notice.