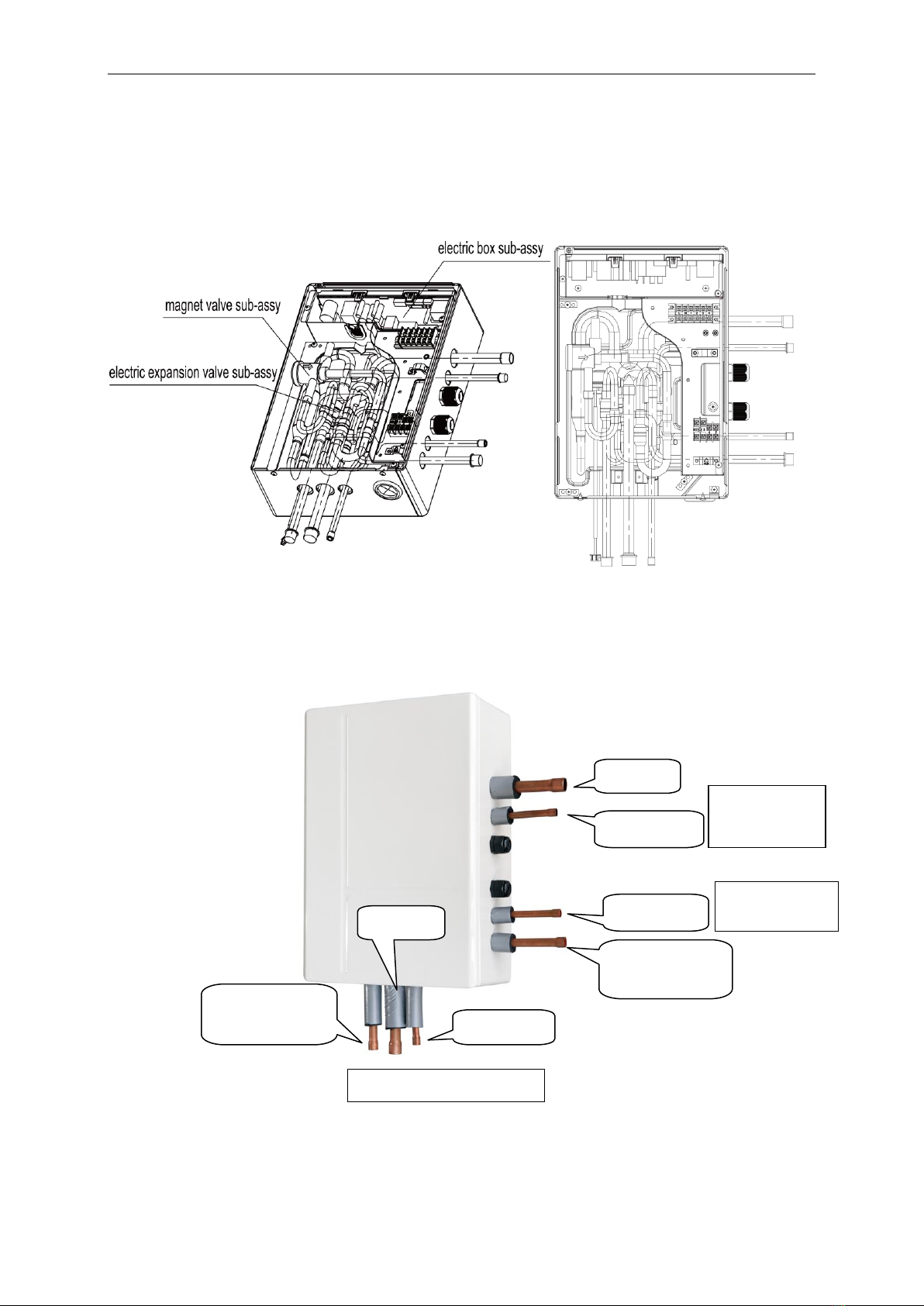

Hotwater converter of CHV5HomeInstallationandOperation Manual

1

1 Introduction to Users

(1)Before conducting any maintenance and repair for the converter, please cut off the

power first; the converter is not allowed to be adjusted or maintained by

nonprofessional personnel.

(2)Please make sure that the power socket is in conformity with the national standard and

be reliably grounded. It is not allowed to use the converter without reliable grounding.

(3)Make sure that the water tank has been filled with water before energizing the unit,

otherwise the unit may be damaged.

(4)Hot water of over 50℃may cause scald, please make sure that the hot water is mixed

with cold water before using the water. When the ambient temperature is below 0℃,

and no people in the room for long, and the converter is de-energized, please drain the

water tank.

(5)After draining the water inside the water tank, please cut off the power of hot water

converter.

(6)Hot water inside the water tank cannot be drunk. Because long-term using of water

tank may generate water scale, and water quality is bad. So please use clean water to

wash the food again after using the water inside the water tank to wash the food.

(7)The default setting water temperature of converter is 50℃. If water temperature is too

high, the COP of unit will decrease accordingly.

(8)The most energy-saving mode is water heating under cooling mode; the unit will

automatically estimate to exert the heat recovery effect to the most.

(9)This unit has fast water heating function.

2 Safety Notices

Please read this manual carefully before using the unit, and operate according to the

instructions.

Please especially pay attention to the meanings of the following signs:

Warning: it means improper operation may cause death or severe damage to people.

Caution: it means improper operation may cause injury to people or damage to property.

Warning!

①Please do not place gasoline or related inflammables near the converter, otherwise it may cause fire or

accident.

②The water temperature value displayed in the display screen of wired controller for water tank is the water

temperature near the detecting probe, generally water outlet temperature of water tank is higher than the

displayed temperature in the display screen. Please add and mix with cold water before using the water, and

then adjust the needed water temperature to avoid scald.

③Power switch of converter should be installed in dry place; do not operate the power switch with wet hands,

otherwise it may cause electric shock or damage.

Caution!

①If the converter is faulted, it should be repaired only by professional aftersales personnel; not professional

person should not remove or maintain the converter.

②When a child taking shower, an adult must instruct aside; do not allow a child to operate the converter.