6

ASSEMBLY AND USER GUIDE

PORTABLE DEIONIZED WATER SYSTEM

Please inspect the system and components inside the box to make sure nothing is damaged during ship-

ping. If the system or any of the components are damaged, please stop the installation and contact Global

Water Solutions for support.

BEFORE INSTALLATION

OPERATING PARAMETERS

GENERAL OPERATING REQUIREMENTS

Please use filtered water or city water.

DO NOT use hot water with this system.

CAUTION

If the system is not being used, store the system indoors.

For storage, avoid exposure to direct sunlight and protect

from the elements. Avoid freezing to prevent damaging the system. If the system

is not being used for more than 3 weeks, relieve hose pressure, open the housings

using supplied wrench, remove cartridges and empty water from housings. Place

cartridges in a location that will not create water damage, i.e., a sink or drain. Allow

cartridges to drain completely before returning them to housings.

SYSTEM STORAGE

WATER SUPPLY

Quality Municipal Water

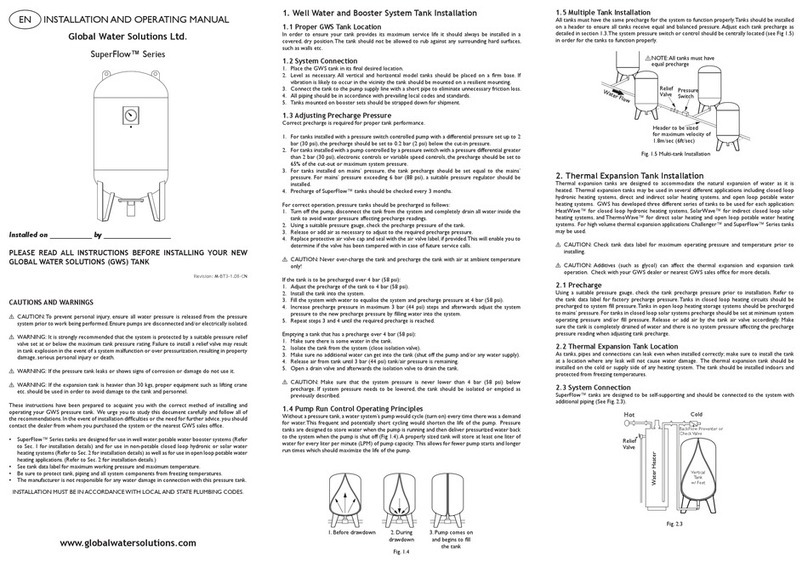

Max. Pressure 125 psi | 8.6 bar

Recommended Pressure 45 psi | 3 bar

Max. Flowrate 2.5 GPM / 9.5 LPM

Recommended Flowrate 1 GPM / 4.5 LPM

Temperature 5°C - 40°C / 40°F - 104°F

PLUMBING

Inlet Water Connection 3/4” Male BSPT Connector

Garden Hose Connection 3/4” Male BSPT Connector

DO NOT drink the water treated by this system. This water is deionized and not suitable for

human consumption.

WARNING

DO NOT use pressure washer or install pressure pump before the system.

Ensure garden hose and sprayer are purged of old water prior to installing with ZeroSpot.

Old water may contain hard minerals and may leave water spots on your car. If purging an old hose is not possible,

then use a separate garden hose and sprayer specifically for this system.

SYSTEM SETUP