Page 4

PERIODIC INSPECTION AND MAINTENANCE

Frequency of inspection and maintenance depends upon the

local climatic conditions and the manual switching duty

imposed on the unit. The sectionalizer does not interrupt fault

currents, so contact wear and oil contamination due to arcing

will be minimal. Thus, maintenance efforts should be directed

primarily toward keeping the unit in operating order and main-

taining the dielectric strength of the insulating oil.

Cooper Power System's recommends that, initially, a mainte-

nance check be made after one year of service. A study of

maintenance records for similar equipment, along with the

results of the initial maintenance check can then be used to

establish realistic maintenance intervals.

Each periodic maintenance check should include at least the

following steps:

1. Bypass, trip and. deenergize the sectionalizer and remove it

from service.

2. Inspect the external components.

A. Check for broken or cracked bushings, paint scratches,

and other mechanical damage.

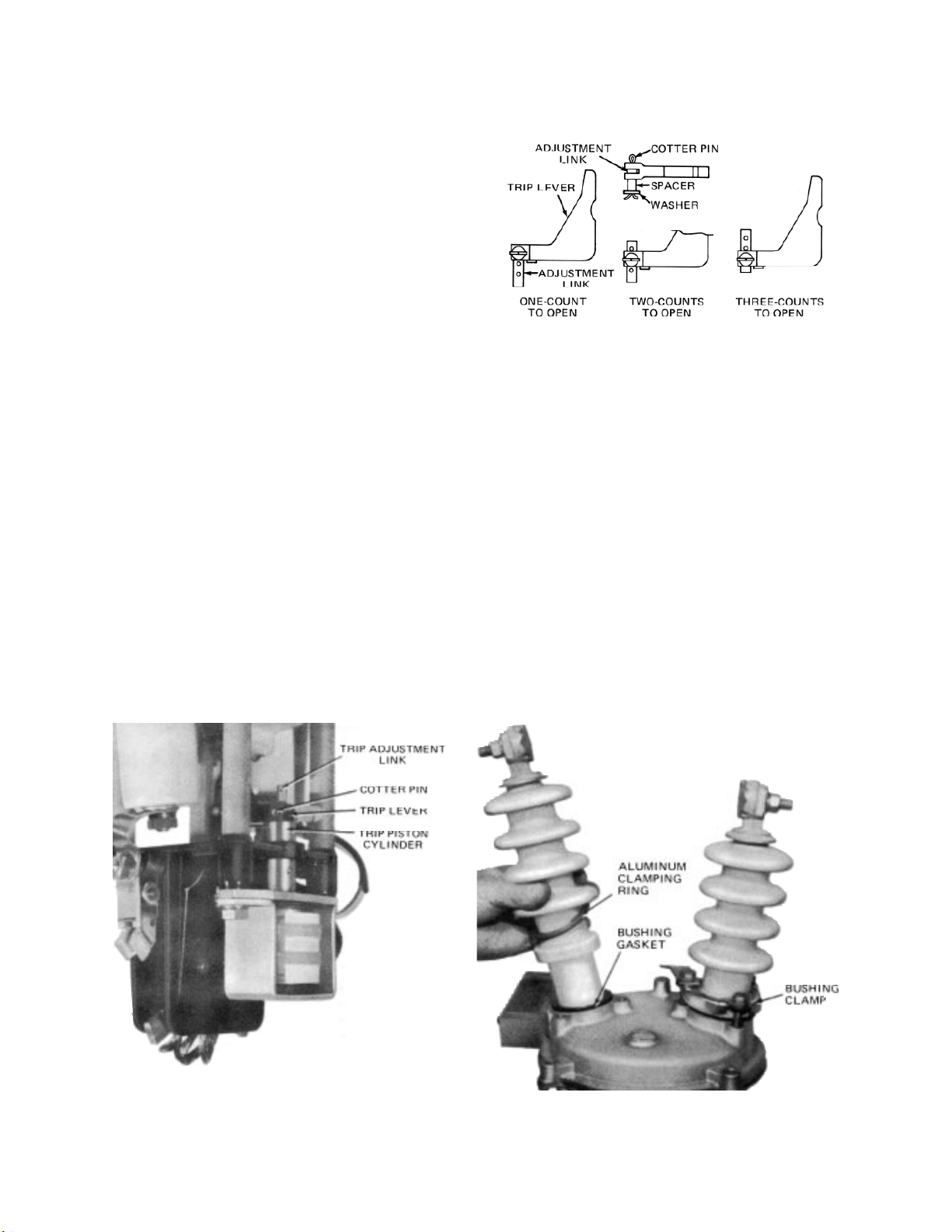

B. Close and trip the sectionalizer manually several times

to check mechanical operation. Leave the unit in the

open position.

3. Remove the bolts and clamps that secure the head casting

to the tank and remove the mechanism from the tank.

Carefully pry apart the head and tank to break the gasket

seal.

4. Allow the oil to drain off the mechanism.

5. Clean the internal components.

A. Remove all traces of carbon by wiping with a clean, lint-

free cloth.

B. Flush the hydraulic mechanism with clean transformer

oil.

6. Check the moving and stationary contacts.

A. Slight pitting and discoloration can be dressed with cro-

cus cloth or a fine-tooth file.

B. Replace the moving and stationary contacts if they are

severely eroded (see “Shop Maintenance Procedures”

section of this manual).

NOTE: The amount of erosion permissible is difficult to define.

Good judgment must be used when deciding whether to

replace the sectionalizer contacts.

7. Operate the control lever manually, and observe if all com-

ponents operate properly. When tripping the sectionalizer in

air, hold or cushion the moving contacts with one hand to

eliminate impact and overstressing of contact box.

8. Inspect tank liners. Soft or spongy areas indicate that water

has been absorbed. Replace both the tank wall

liner and tank bottom liner if this condition is detected.

NOTE: The 125-kv BIL unit has an additional wall iiner between

the standard liner and the tank which must also be replaced when

new liners are installed.

9. Check the dielectric strength of the insulating oil.

A. The dielectric strength should not be less than 22 kv

when tested with an 0.1-inch gap in accordance with

methods specified in ASTM D-117.

B. Low dielectric strength usually indicates the presence

of water or carbon deposits; replace the oil.

10. If oil must be replaced, drain the tank and clean out all

sludge and carbon deposits.

11. With the mechanism removed, fill the tank with clean insu-

lating oil to the top of the tank wall liner. Capacity is

approximately 1-1/2 gallons.

Use only new, or like-new reconditioned transformer oil

which conforms to the specifications in Cooper Power

System's Reference Data R280-90-1, “Oil Specifications

and Test”.

12. Examine the head gasket. Replace the o-ring gasket if it

has taken a permanent set.

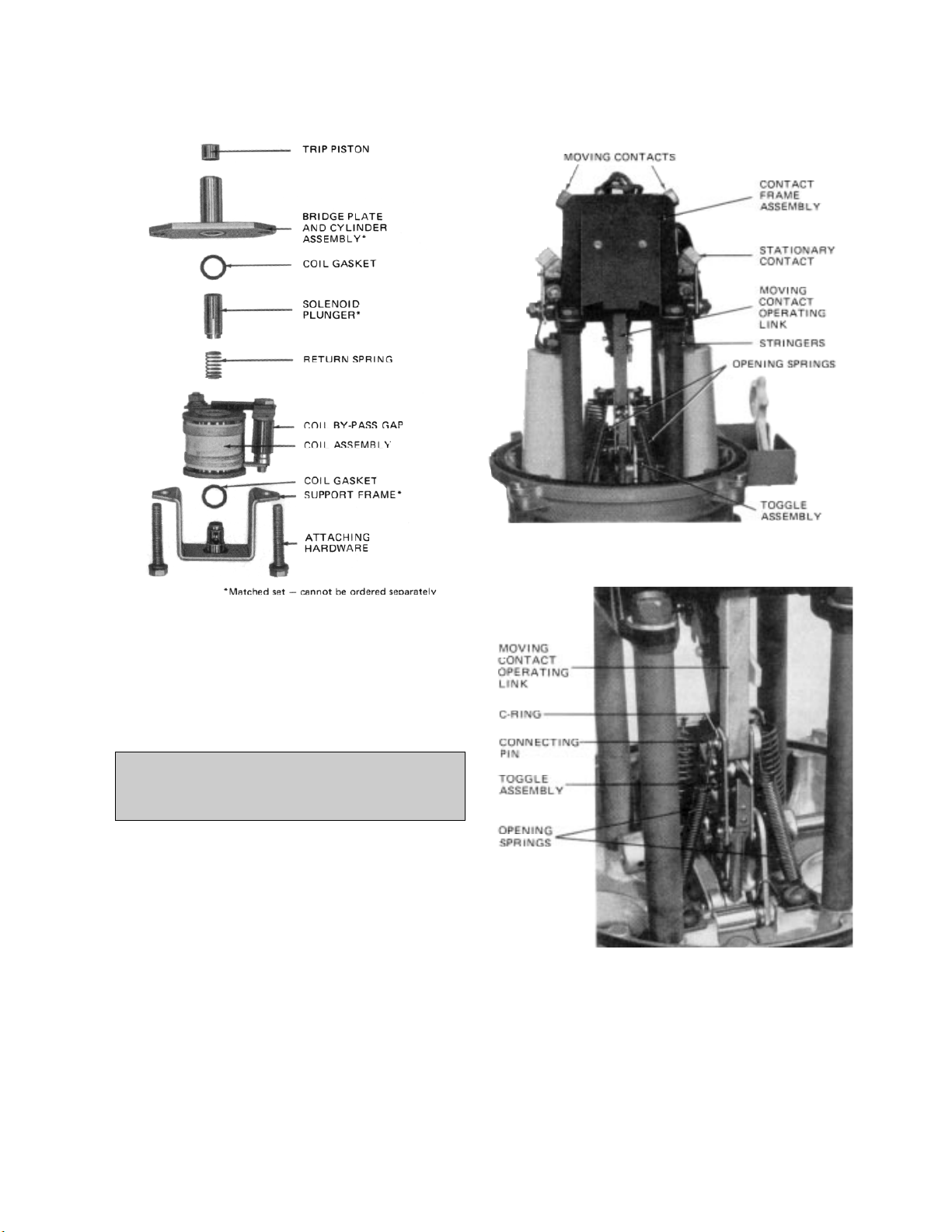

13. Before retanking the sectionalizer, invert and prime the

hydraulic mechanism by introducing new transformer oil

with an ordinary squirt can through the hole in the bottom

of the coil frame. Then, quickly place the mechanism into

the tank far enough to cover the hydraulic mechanism with

oil. With a slender tool, such as a small Allen wrench,

push down the trip piston to clear air from the hydraulic

parts.

14. Reuse the head bolts and tank clamps and torque to 10-

14 ft -lbs. Clamping forces must be applied gradually and

equally in rotation to each bolt. This results in an evenly

distributed gasket sealing pressure.

15. Manually close and open the unit several times to expel all

air from the hydraulic system and to check the mechani-

cal operation.

16. Check if the unit is operating properly.With the sectionaliz-

er closed, momentarily connect a six-volt storage battery

across its bushing terminals. Repeat this procedure at

about one-second intervals and note if the sectionalizer

opens after the correct number of operations has

occurred. If the unit does not lock out properly, wait about

three minutes and repeat the test. Air entrapped in the

hydraulic system can cause incorrect operation.

If the unit still fails to operate properly, disassemble the

hydraulic mechanism as described in “Shop Maintenance

Procedures”. Check carefully for sludge accumulation,

dirt, or scratches on any of the parts. Clean the parts and

carefully reassemble the mechanism. Cleanliness is

very

important. Recheck the unit for proper operation.

OIL CONDITION

Oil plays an important role in the proper functioning of the

sectionalizer. It provides the internal insulation barrier from

phase-to-ground, and it acts as an arc quencher during man-

ual load switching.For effective sectionalizer operation, the

CAUTION

Never use volatile solutions, detergents, or water-soluble

cleaners.