Introduction

Service Information S270-20-3 provides installation and

operation instructions for the Kyle Type GV and GW

Sectionalizers. Before installing and operating this sec-

tionalizer, carefully read and understand the contents of

this manual.

Read this Manual First

Read and understand the contents of this manual and

follow all locally approved procedures and safety prac-

tices before installing or operating this equipment.

Additional Information

These instructions can not cover all details or variations

in the equipment, procedures, or processes described

nor provide directions for meeting every possible contin-

gency during installation, operation, or maintenance. For

additional information, please contact your Cooper

Power Systems representative.

Acceptance and Initial

Inspection

Each sectionalizer is completely assembled, tested,

inspected, adjusted, and filled to the correct level with

insulating oil at the factory. It is in good condition when

accepted by the carrier for shipment.

Upon receipt, inspect the shipping container for signs of

damage. Unpack the sectionalizer and inspect it thor-

oughly for damage incurred during shipment. If damage

is discovered, file a claim with the carrier immediately.

Check for oil leakage, and tighten all bolts that may have

been loosened during shipment, especially the bolts

attaching the head to the tank.

Handling and Storage

Be careful during handling and storage of the sectional-

izer to minimize the possibility of damage. If the section-

alizer is to be stored for any length of time prior to instal-

lation, provide a clean, dry storage area. Locate the sec-

tionalizer so as to minimize the possibility of mechanical

damage. In particular, protect the bushings and keep the

operator cabinet closed to protect the electronic control

components.

Standards

Kyle sectionalizers are designed and tested in accor-

dance with ANSI standard C37.63 where applicable.

Quality Standards

ISO 9001:2000 Certified Quality Management System

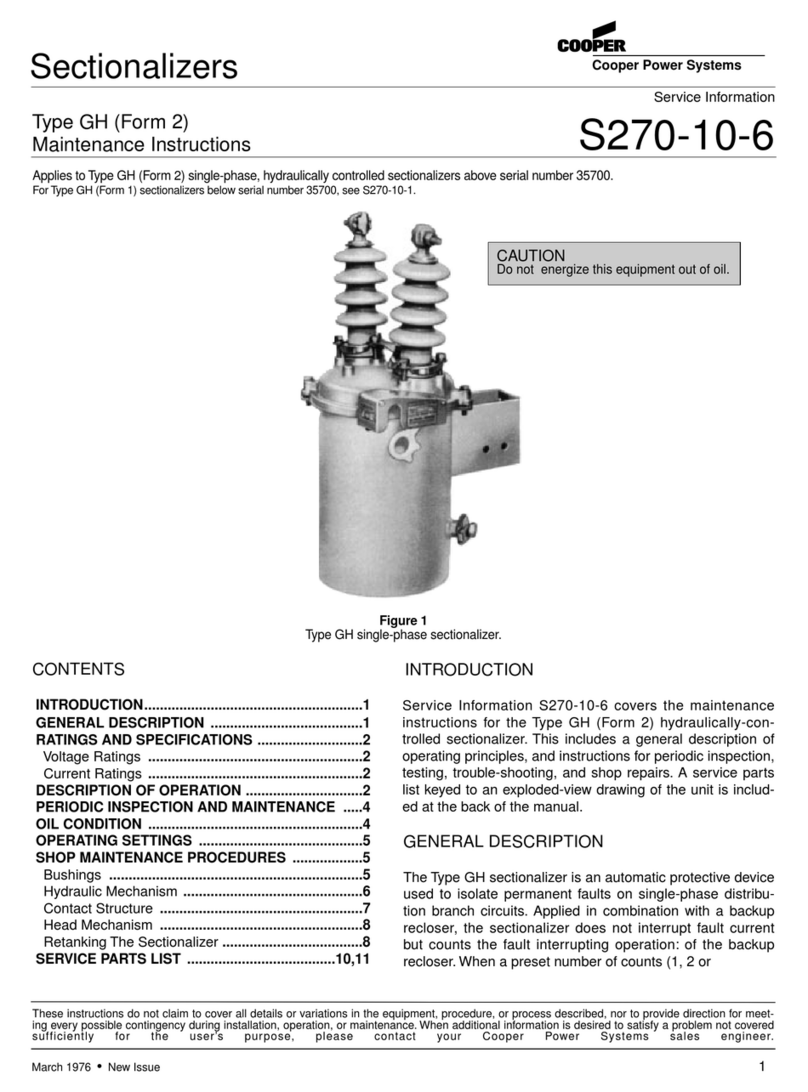

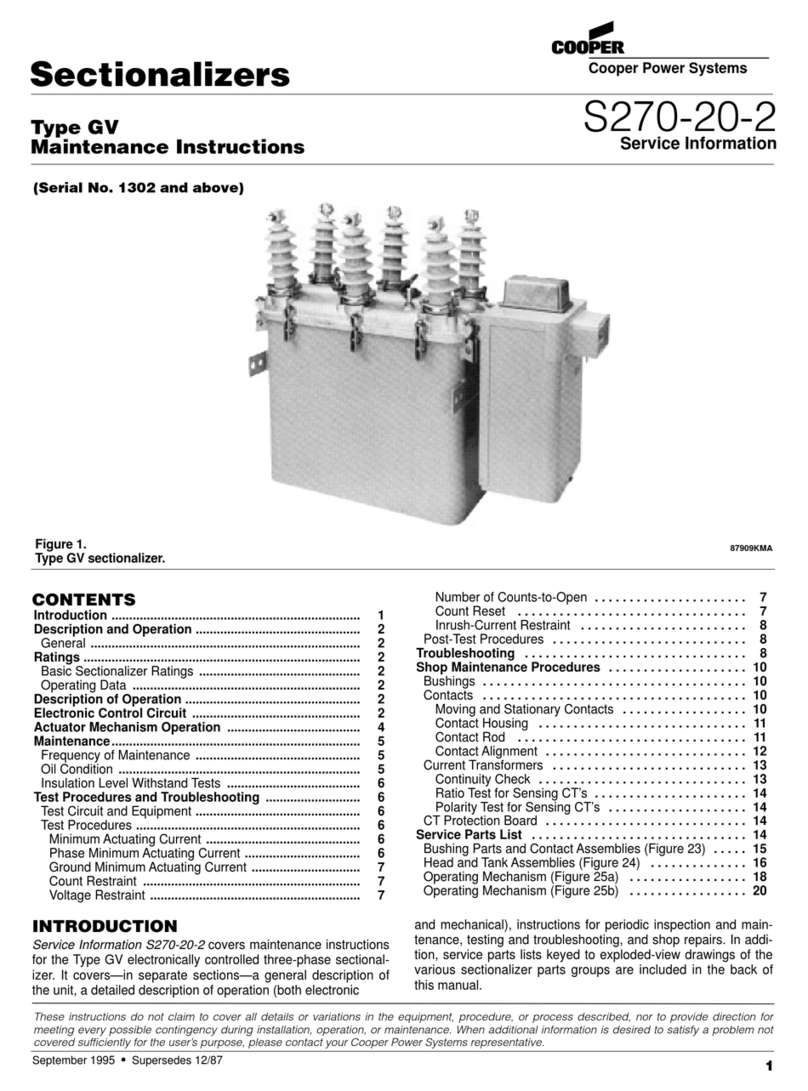

Description

The sectionalizer is a self-contained, circuit-opening

device used in conjunction with source-side protective

devices such as reclosers or circuit breakers, to auto-

matically isolate faulted sections of electrical distribution

systems. The sectionalizer senses current flow above a

preset level, and, when the source-side protective

device opens to de-energize the circuit, the sectionalizer

counts the overcurrent interruption. Depending upon the

coordination scheme, the sectionalizer will open during

the first, second, and third open interval of the fault inter-

rupting device to isolate permanent faults and confine

outages to smaller sections of line.

The sectionalizer does not interrupt fault current but can

be closed into a faulted line. It opens during the open

interval of the backup device. For this reason, it must

always be used in series with a fault-interrupting backup

protective reclosing device. Also, it will reset counts that

do not reach the counts-to-open setting within the

selected reset time due to clearing of temporary faults.

A minimum of 0.5 A of load current flowing through the

sectionalizer will block the generation of a count pulse.

This count-restraint feature prevents the sectionalizer

from counting overcurrents interrupted by down-line

devices.

The sectionalizers are also equipped with an inrush-current

restraint feature which distinguishes between inrush cur-

rents and fault currents. If it is determined that the over-

current through the sectionalizer is inrush current, the

phase and ground current levels of the sectionalizer are

blocked for a duration of 3 seconds upon current detection.

3

S270-20-3

PRODUCT INFORMATION