2. Odour due to downtime / storage

a. Smells Musty to "chemical"

b. Evaporates after a few days of ventilation

c. Action: Set the ventilation device to the

highest air exchange rate when you are not

at home and repeat the process until the

odour evaporates.

3. Odour transmission (Exchange of odours in the air

currents via the membrane)

a. Smell depending on the smell transmitted

and smells from outside or from other

rooms (very critical onions and garlic,

smoke? Tar?)

b. Evaporates after a few days of ventilation

c. Action: Set the ventilation device to the

highest air exchange rate when you are not

at home and repeat the process until the

odour evaporates. (We recommend an

extractor hood, especially if there are

kitchen smells!)

•

4. Odour due to unknown influences / damage

a. Odour undetermined (source unknown)

b. Builds up more and more over time and

does not dissipate after a few days or

weeks.

c. Please contact your service technician. You

can check a number of parameters yourself

in advance: checking the device settings,

air distribution and filter systems.

In addition to odours from the inside, odours from the outside

can also get into the interior via the ventilation system. These

odours can be "picked up" by the ERV and linger for a long

time.

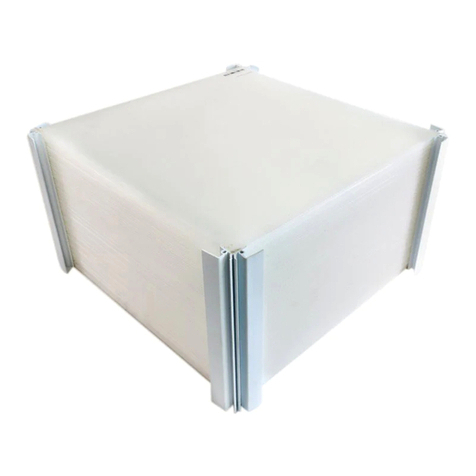

With the products HRV and ERV there can be a small amount

of odour transmission due to air exchange through leakage.

However, this exchange takes place to such a small extent

that only substances with a very low odour threshold can be

perceived.

The risk of odour transmission is slightly higher with ERV

because, in addition to leakage, transmission via the

membrane cannot be 100% ruled out. The membranes we

use are technically of a very high standard and very selective

with regard to water molecules. This makes it difficult for

other molecules, e.g. VOC (volatile organic compounds), to

pass through the membrane.

Measurements show that, depending on the chemical

substance class and molecular size, organic compounds up

to 99% are blocked by the membrane.

Notes radioactive noble gas radon

When uranium and radium are present in varying degrees in

all soils and rocks decay, radon is produced, which spreads

through the soil and finally reaches the earth's surface.

Radon also reaches the interior of houses from the subsoil

of buildings, where it can accumulate. This can lead to high

radon concentrations, which are hazardous to health,

especially if the room is not ventilated very often.

Radon concentrations in the soil, in the air and indoors vary

locally and regionally.

The membrane of the ERV is permeable to air and thus also

to noble gases such as radon to a certain extent. However,

due to the membrane permeability, the exchange of radon

from supply and exhaust air is far below the exchange of air-

air due to the average leakage of an ERV or the ventilation

system itself.

By using a ventilation system in general, you ensure that

more fresh air gets into the interior and that accumulation

with radon, which can lead to a health hazard, can be

prevented. All of this is independent of whether you run an

ERV or an HRV in your ventilation system.

Notes Use on ships, coastal areas and islands

The ERV is a component for energy recovery (recuperation)

for ventilation units designed for living spaces. However, the

composition of the airflows has a strong influence on the

aging of the ERV.