1

1. Introduction ........................................................................................................................................2

1.1 Purpose and content ................................................................................................................2

1.2 Symbol and meaning................................................................................................................2

1.3 Users of This Manual ................................................................................................................2

1.4 Manual Lost and Reissued......................................................................................................2

2. Safety Guide........................................................................................................................................3

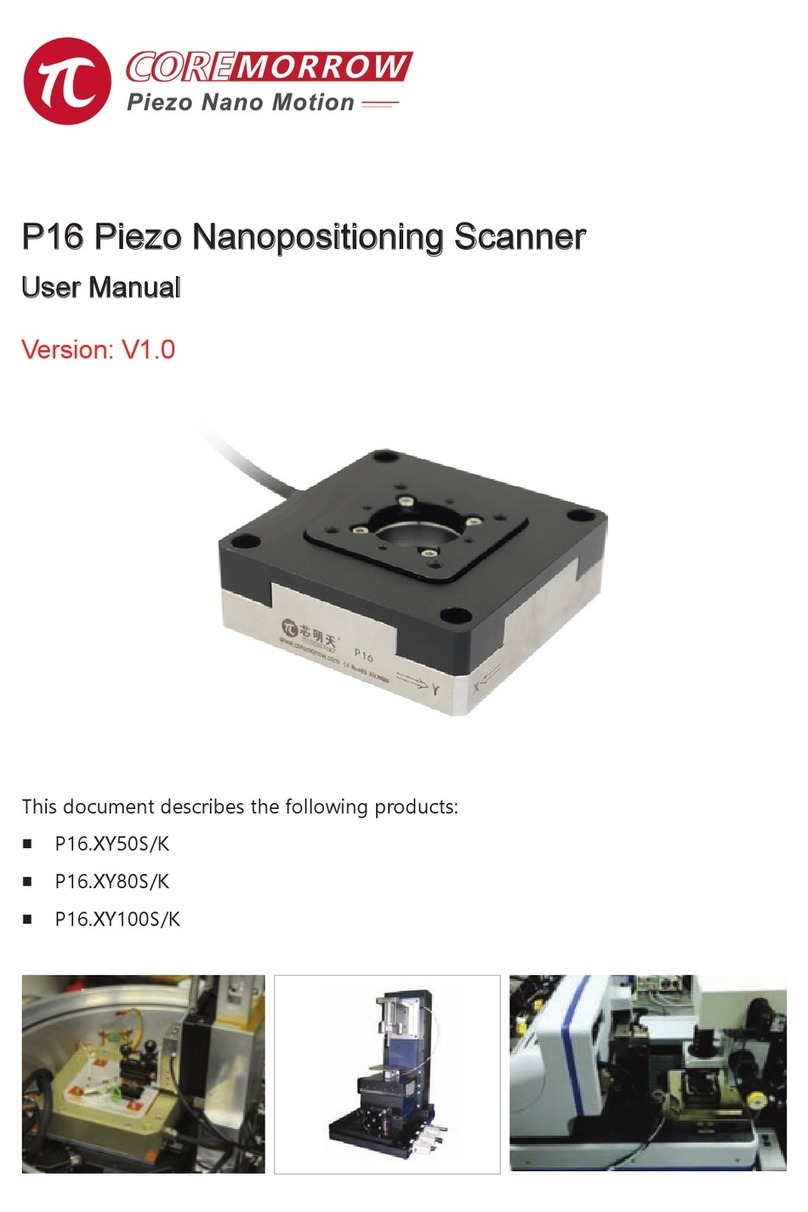

3. Product Overview ...........................................................................................................................4

3.1 Product Introduction ................................................................................................................4

3.2 Product Features........................................................................................................................5

3.3 Motion direction ........................................................................................................................5

4. Operating environment ..................................................................................................................6

5. Installation and operation..............................................................................................................6

5.1 Installation and Precautions...................................................................................................6

5.2 Load................................................................................................................................................8

5.3 Operating...................................................................................................................................10

6. Transportation and inspection ..................................................................................................12

6.1 Transportation..........................................................................................................................12

6.2 Open-Box Inspection.............................................................................................................12

7. Maintenance and Treatment ......................................................................................................13

7.1 Problem Handling...................................................................................................................13

7.2 Daily maintenance..................................................................................................................14

7.3 Disposal......................................................................................................................................14

8. Parameter..........................................................................................................................................15

8.1 Technical data...........................................................................................................................15

8.2 Drawing......................................................................................................................................15

8.3 Driving and Sensor Connector...........................................................................................16

9.Customer Service ............................................................................................................................17

10.Contact us........................................................................................................................................17

Contents