HO Structure Kit

UPS®HUB WITH

CUSTOMER CENTER

933-4110

© 2017 Wm. K. Walthers, Inc., Milwaukee, WI 53218 waltherscornerstone.com I-933-4110 Printed In Taiwan

6

13

213

2

13

2

13 313

12

42

43

24

44 x6

26 x6

25

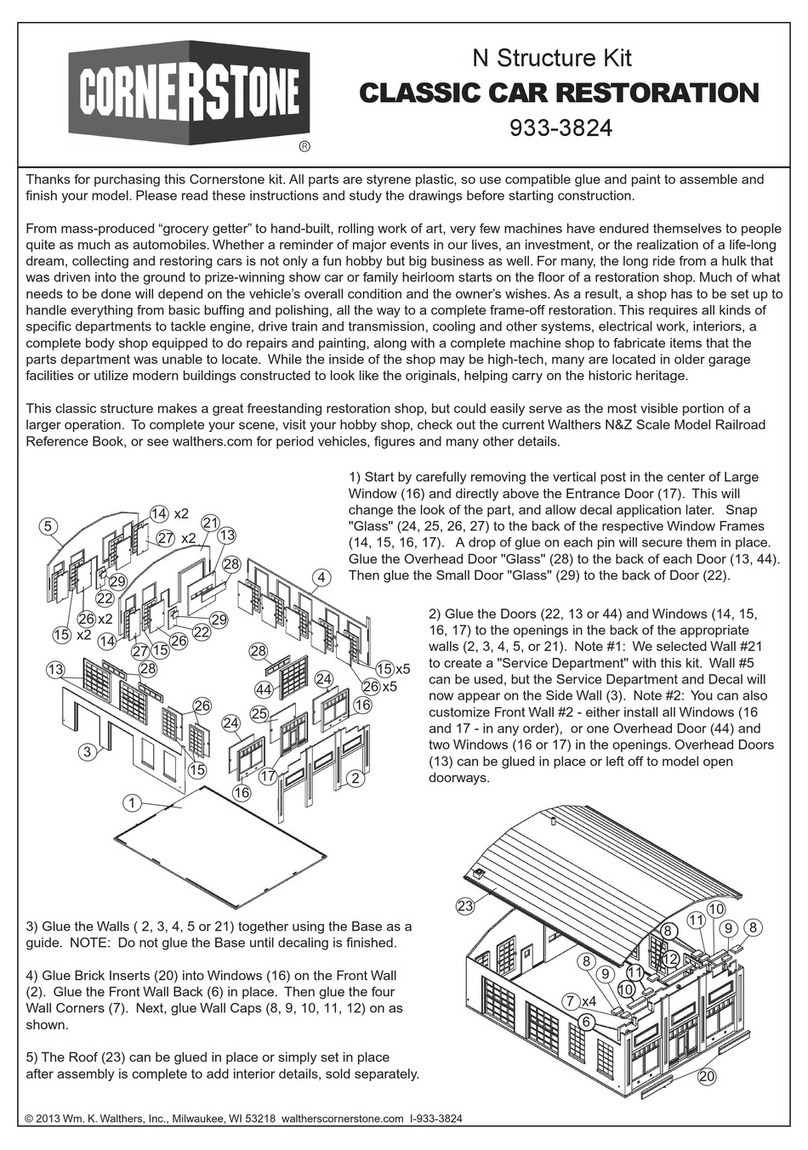

Thanks for purchasing this Cornerstone kit. All parts are styrene plastic, so use compatible glue and paint to assemble and

finish your model. Please take a few minutes to read these instructions and study the drawings before beginning. PLEASE

NOTE This model is based on ³tip-up² buildings in use since the 1980s, and like the prototypes, consists of interchangeable

wall panels that can be arranged as desired to customize your structure. These instructions cover a typical assembly, however

you can use fewer parts to make a smaller structure, or combine complete kits and matching Truck and Railroad Docks wall

panels (#933-4070 sold separately) for a bigger building. The SceneMaster Modern Wall Light 3-Pack #949-4318, sold sepa-

rately) may be used in place of the five nonworking light fixtures (57); to assemble your model as shown here, you¹ll need two

sets. For ease of assembly, you may wish to have these additional parts on hand before starting. Some parts included in this

kit are not needed for assembly, and can be kept for future projects or discarded as desired.

Starting operations as the American Messenger Service from a single basement office in 1907, 19-year old James Casey laid

the foundation for what would become United Parcel Service. Today UPS centers like this can be found in many industrial and

commercial areas, providing shippers with convenient service and expedited delivery to destinations around the world. Your

new model is typical of larger facilities that transfer packages for both long-distance and local delivery, handling trailers as well

as drive-in loading for Package Cars and light trucks. A convenient service center is also provided where customers can quickly

ship smaller packages. To bring your new UPS Hub with Customer Service Center to life, SceneMaster offers 20 officially

licensed UPS vehicles to model delivery services, and for the finishing touch, add the UPS Personnel with Hand Cart figure set

(#949-6043) each sold separately. For additional ideas and supplies, see your local hobby shop, check out the latest Walthers

Reference Book, or visit us online at walthers.com.

BEFORE STARTING...

All wall panels are glued together on the back using molded locater pins and separate connector plates as shown. A raised

ridge is molded at the bottom to align with the base: double walls also have a raised ridge at the top to support the roof, and

corner walls have a third raised ridge along the outside edge. When assembling wall sections, work on a flat surface and allow

parts to dry.

TRAILER LOADING DOCK - Assemble from Left to Right

1) Begin by gluing Steel Entry Door (25) to opening in

rear of Entry Panel Wall (6).

2) PLEASE NOTE: Optional Canopies (6x 65) are provid-

ed for each truck door (see last page for illustration); if

you wish to use these parts, drill out mounting holes on

the backs of Walls (2) using a .060" (1/16" 1.5mm) bit -

canopies will be installed in step 15. When assembling

the Truck Dock Door Panels (2, three shown), the Truck

Doors (6x 26, two per wall) can be left off to model an

open door: for a closed door, glue Overhead Door Glass

(2x 44 per door - six total) to rear of Truck Doors.

3) Assemble the Double Office Wall (12) by gluing the

Glass Entry Door (42) and Large Window (43) in place:

both use Large Glass (24): align Glass with locating pins

on back of frames and glue where parts meet.

4) Work on a flat surface and connect individual wall

sections (6, 3x 2, 3 &

12) by aligning openings in Large Connector (5x 13) with

raised pins on back of walls and gluing where parts meet

as shown.