HO Structure Kit

STEEL RAILROAD

BRIDGE TOWER

933-4554

©2015 Wm. K. Walthers, Inc. Milwaukee, WI 53218 Printed in China I-933-4554

1

14

15

7

12

10

8

13

611

5

9

4

2

26

20

19

18

18

18

18

19

20

Thanks for purchasing this Cornerstone® kit. Please read these instructions and study the drawings before starting construction.

Allparts are styrene, so use compatible glue and paint to finish your model. As part of the Cornerstone Engineered Bridge

System, walthers.com/bridgesystem, your new model can easily be used with other Cornerstone bridges and accessories to

create a custom structure for your railroad.

Deep valleys, broad rivers, gorges and similar obstacles proved to be among the biggest challenges to early railroad builders.

Whereconstruction of a standard bridge or trestle was difficult, engineers wouldbuild a viaduct. These were originally complex

affairs made of cut stone with multiple arches supporting a deck. Later poured concrete was used, but as the steel industry

matured in the early 20th century, beams, columns and other heavy-duty construction components became readily available.

Durable and cheaper steel quickly became a popular choice for trestle bents (which can be modeled with kit #933-4555 sold

separately). Where a taller support structure was required, bents were combined in pairs with additional bracing for strength and

stability to build viaduct towers. These might be built at different heights (“stories”) to fit the terrain, but were sometimes used with

bents at the lower ends of the span, which was typically a series of all-steel plategirder deck bridges. Today, many of these sturdy

steel viaducts are still in daily railroad service. For more ideas and information on the Cornerstone Engineered Bridge System

please visit walthers.com/bridgesystem. For additional products to complete your scene, see your participating hobby dealer,

check out the latest Walthers Model Railroad Reference Book or visit us online at walthers.com.

BEFORE STARTING CONSTRUCTION…

This kit is designed especially for use with Cornerstone Single Track Deck Girder Bridges, available in multiple lengths from 30

to 90 scale feet (kits #933-4505 to 4509, each sold separately). We suggest test fitting each tower as a subassembly directly on

your layout to determine final placement. Be sure each is level and correctly aligned before attaching thebridges and making the

final installation. With some careful kitbashing, towers of different heights can be built for uneven terrain. The lower edge of

thegusset plates on the A-Frames and Horizontal Braces can be used as a cutting guide. Cut each leg in the same spot, and care-

fully trim away the lower half of the plate.

Bent Assemblies

Make two as follows:

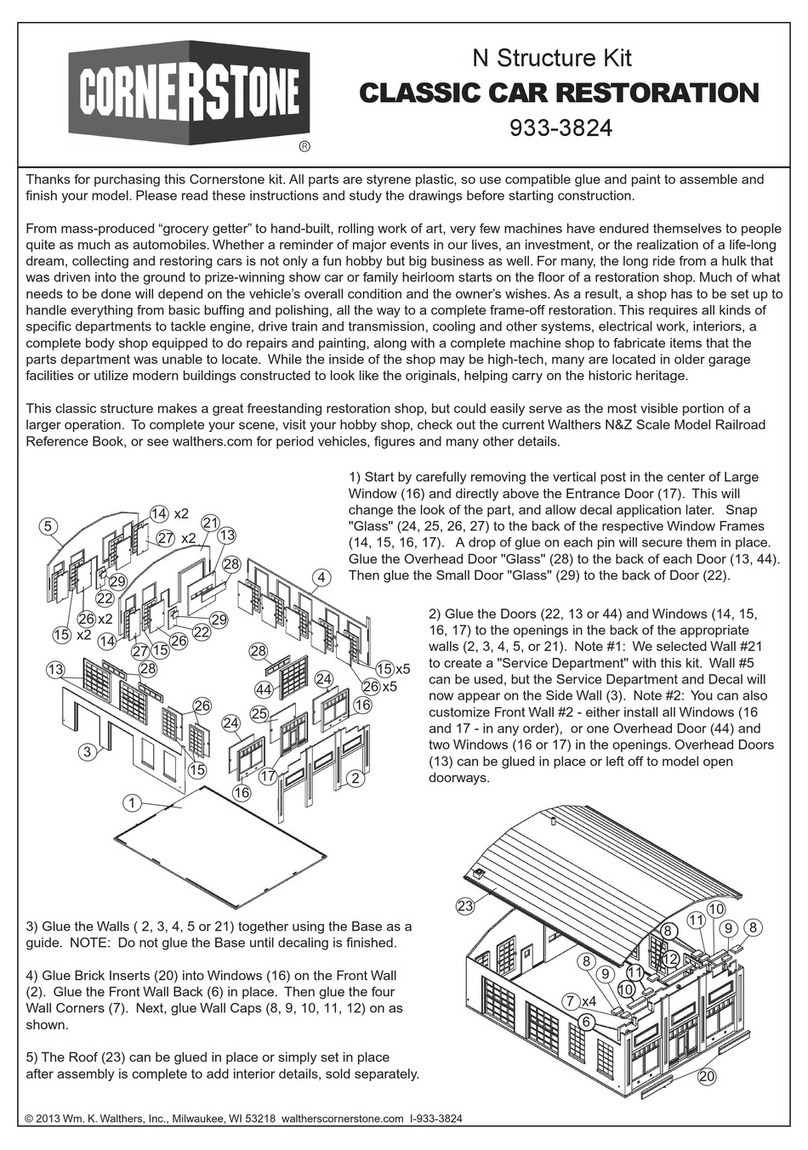

1) Note the raised ridges on the inside edges of

A-Frames (1) to help align cross braces. Glue both

edges of Base (4), Large (5), Medium (6) and Top

(7) Horizontal Braces to the slots between ridges

as shown.

2) PLEASE NOTE: Assemble all four Diagonal

Braces as shown (#8 & 9, 10 & 11, 12 & 13, and 14

& 15) by inserting - do not glue - parts in an

X-shape. Align the upper and lower ends of the

Diagonal Braces between the raised pegs on the

backs of each gusset plate. Adjust asneeded so

parts fit square and snug, and apply a little glue

where the Diagonal Braces meet the plates and

Horizontal Cross Braces.

3) Note the small pins and sockets on the inside to

help align the front and rear half of each A-Frame

(1). Make sure all cross braces are aligned and

glue second A-Frame in place.

4) With the rivet details facing inwards, use the

inset areas on the back to align Lacings, (4x #18

and 2x each #19 & 20) and glue to left and right

inside edge of A-Frame assembly.