HO Structure Kit

BASCULE BRIDGE

933-3070

© 2016 Wm. K. Walthers, Inc., Milwaukee, WI 53218 waltherscornerstone.com I-933-3070 Printed In China

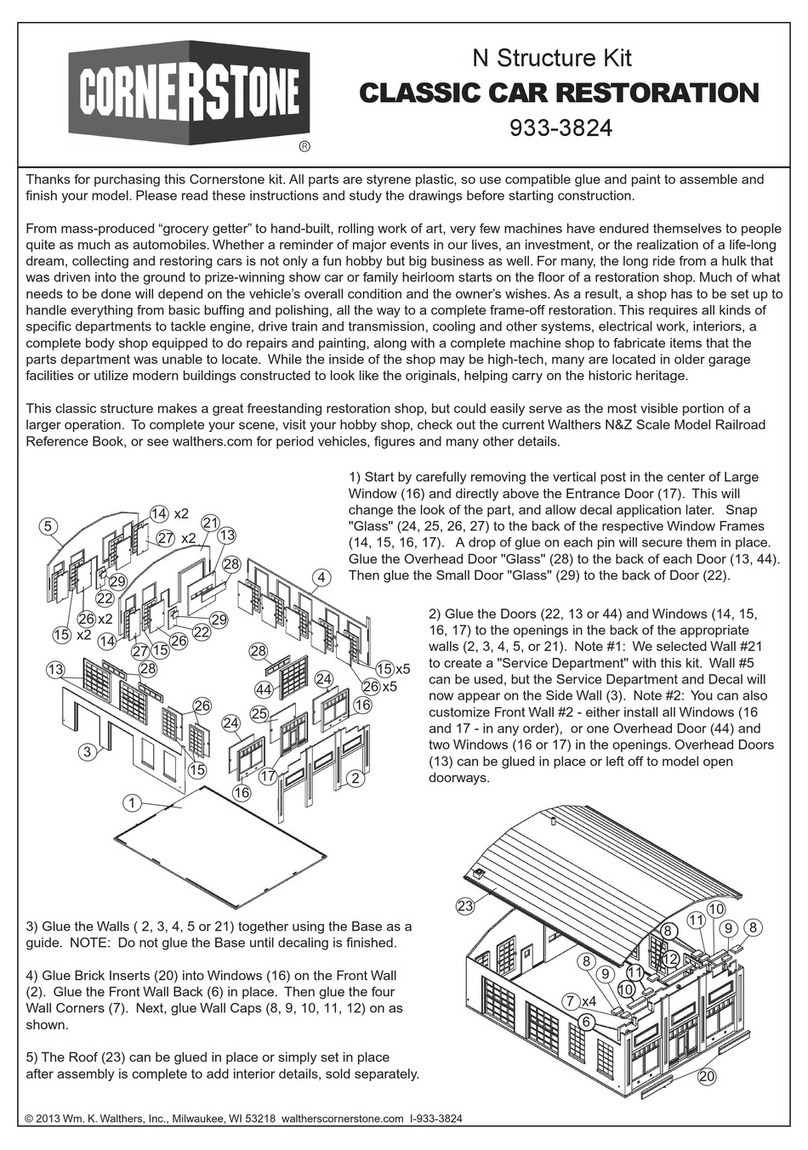

Thanks for purchasing this Cornerstone® kit. Please read these instructions and study the drawings before starting

construction. All parts are styrene, so use compatible glue and paint to finish your model. As part of the Cornerstone

Engineered Bridge System, walthers.com/bridgesystem, your new model can easily be used with other Corner-

stone bridges and accessories to create a custom structure for your railroad. PLEASE NOTE: your new bridge is

designed as a working model. The gears in the drive mechanism are made of Delrin® plastic and should be lubri-

cated with a light, plastic-compatible grease before operation.

Rivers have always challenged railroad bridge builders, especially where the waterway is used for commercial

shipping. While pleasure boats require very little clearance, ocean-going freighters or large naval vessels must also

be able to pass safely. In congested urban areas, the best choice for the job is a Bascule bridge.

Fixed at one end to open and close like a jackknife, the basic idea dates back centuries, a common example being

drawbridges over moats protecting medieval castles. For railroads, the design has many advantages. Smaller and

simpler, they have fewer moving parts than other movable bridges, so they’re cheaper to build and maintain. Their

greatest advantage however is that they can be partially raised to quickly clear small vessels, then closed, making

them an ideal choice for busy rail lines.

The actual lifting work is done by a large counterweight, with help from a heavy-duty electric motor and gear drive

to overcome its inertia. As the balance point is reached, the motor shuts off and gravity takes over, raising the

bridge.

Because approaching vessels have the right-of-way, the bridge must be manned 24 hours a day; where a channel

is closed during winter months, the bridge is left in the down position. So that the bridge tender has a clear view of

the waterway and the railroad, a crow’s nest is mounted at the fixed end. Today, he or she is in radio contact with

passing trains, as well as approaching vessels since advance notice is required to coordinate safe movements.

Before centralized traffic control, an interlocking tower was an integral part of the bridge, where the operator

controlled signals regulating movement of trains across the structure. Railroads preferred to build single-track

bridges, and it was easier to funnel a double-track mainline into a single track, with additional turnouts and signals

on each side.

For added safety, all signals interlocked with the lifting mechanism so a signal to proceed could only be displayed

when the bridge was closed. While the lowered counterweight would effectively stop an approaching train on that

side, some roads also installed derails (special track switches that would actually derail the train) or “smash boards”

(similar to a semaphore blade that hung over the tracks) if the engineer failed to stop.

While the majority of Bascule bridges were stand-alone installations, if conditions required approaches standard

bridges were used. The Bascule Bridge was installed over the deepest part of the channel, where the largest

vessels would pass.

Due to their heavy steel construction and regular maintenance, many of these bridges have provided decades of

service and remain in daily operation. In some areas where shipping traffic was diverted or eliminated, moving

bridges are no longer needed. But since they are expensive to replace and are in useable condition, the existing

Bascule Bridge was simply left in place.

Based on a Northern Pacific bridge crossing the Duwamish River in Seattle, Washington, and still in use by BNSF,

similar Bascule Bridges can still be found on all types of railroads today. To prevent derailments or severe damage

to the structure, they’re fitted with special track and guardrails, which can easily be added to your model with

Walthers Code 83 Bridge Track with Separate Approach Ends (#948-886, sold separately). To simplify installation

in new or existing scenery, Single-Track Railroad Bridge Concrete Abutments (#933-4551) are available separately.

For more ideas and information on the Cornerstone Engineered Bridge System please visit

walthers.com/bridgesystem. For additional products to complete your scene, see your participating hobby dealer,

check out the latest Walthers Model Railroad Reference Book or visit us online at walthers.com.