CORNING Eclipse User manual

003-499, Issue 4

STANDARD RECOMMENDED PROCEDURE 003-499 | ISSUE 4 | SEPTEMBER 2015 | PAGE 1 OF 5

Eclipse®Wall-Mount Housing

related literature | Search www.corning.com/opcomm. Click on “Resources.”

0170_NAFTA_AEN Eclipse Hardware Product Family Specication Sheet

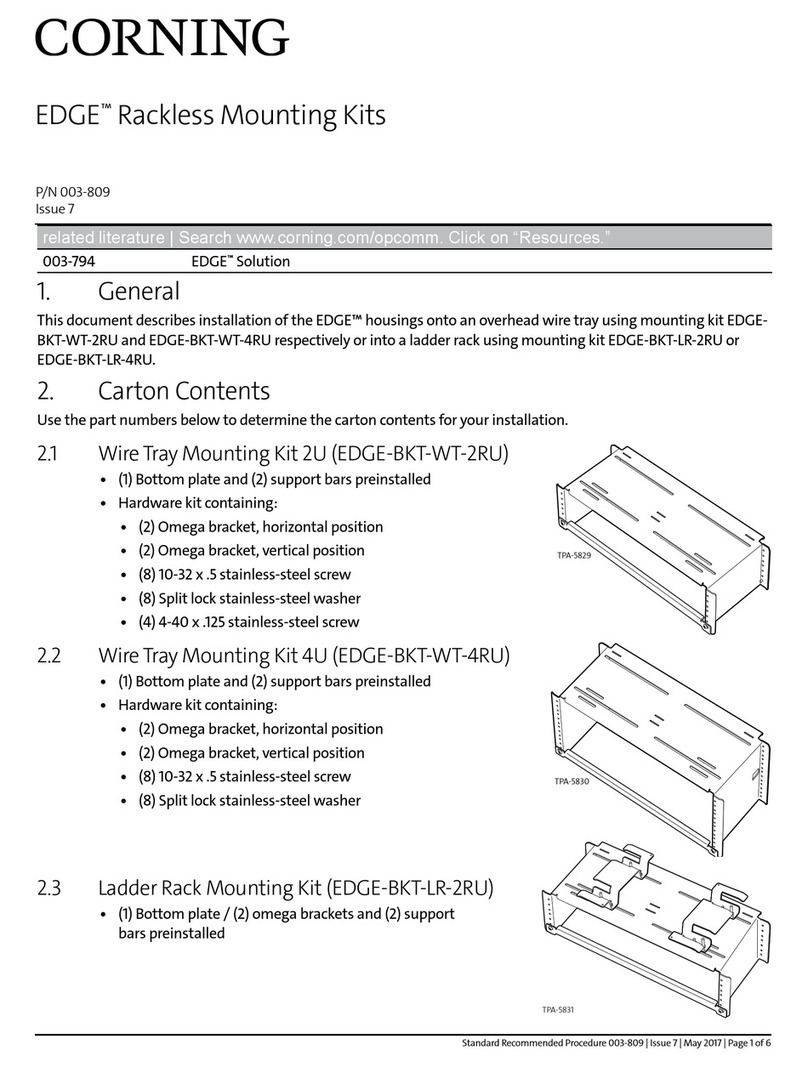

1. Components

• (1) ECL-W3P or (1) ECL-W6P housing

• (12) Cable ties

• (2) Strain-relief brackets

• (4) 6-32 black screws

• (2) Lock nuts

• (1) Hardware kit:

• (2) 6-32 screws

• (2) M6 washers

• (2) U-washers

• (2) Nuts

2. Tools and Equipment

In addition to the usual complement of installation tools, you will need 5/16-inch and 3/8-inch

nut drivers.

3. Precautions

WARNING: Never look directly into the end of a ber that may be carrying laser light. Laser light can

be invisible and can damage your eyes. Viewing it directly does not cause pain. The iris of the eye will not

close involuntarily as when viewing a bright light. Consequently, serious damage to the retina of the eye

is possible. Should accidental eye exposure to laser light be suspected, arrange for an eye examination

immediately.

Provider side

Connector panels

Customer side

Fiber

retaining

guides

Splice tray

UCC

Fiber storage area

Fan-out

location

TPA-3010

• (1) Cable clamp kit:

• (1) Cable clamp

• (2) 6-32 at head screws

• (1) 10-32 lock washer

• (1) #10 washer

• (2) Plastic bases

• Sand paper

• Shims (2 each of various sizes)

• (1) Spacer for smaller diameter cables

STANDARD RECOMMENDED PROCEDURE 003-499 | ISSUE 4 | SEPTEMBER 2015 | PAGE 2 OF 5

CAUTION: Cleaved or broken glass bers are very sharp and can pierce the skin easily. Do not let

these pieces of ber stick to your clothing or drop in the work area where they can cause injury later.

Use tweezers to pick up cleaved or broken pieces of glass bers and place them on a loop of tape kept

for that purpose alone. Good housekeeping is very important.

CAUTION: Recommend the use of safety glasses (spectacles) conforming to ANSI Z87, for eye

protection from accidental injury when handling chemicals, cables, or working with ber. Pieces of glass

ber are very sharp and have the potential to damage the eye.

CAUTION: The wearing of cut-resistant safety gloves to protect your hands from accidental injury when

using sharp-bladed tools and armored cable is strongly recommended. Use extreme care when working

with severed armor. There will be a sharp edge where armor is cut. To minimize the chance of injury

from the cut armor, cover the exposed edge with a wrap of electrical tape. To minimize the chance of

injury from sharp-bladed tools, always cut away from yourself and others. Dispose of used blades and

armor scrap properly.

CAUTION: Fiber optic cable is sensitive to excessive pulling, bending, and crushing forces. Consult

the cable specication sheet for the cable you are installing. Do not bend the cable more sharply than

the minimum recommended bend radius. Do not apply more pulling force to the cable than specied.

Do not crush the cable or allow it to kink. Doing so may cause damage that can alter the transmission

characteristics of the cable; the cable may have to be replaced.

4. Wall-Mounting

Step 1: Select a at, vertical surface to prevent warping of the unit.

Step 2: Hold the unit in position on the wall and mark the hole locations with a pencil.

Step 3: Drive wood screws or anchors in at the top two locations leaving a 1/8-inch gap

between

the mounting surface and screw head. (Hardware used for mounting depends on the

mounting surface.)

Step 4: Place the unit on the mounting hardware and tighten the screws.

Step 5: Drive the two remaining screws through the mounting holes in the bottom of the

housing.

9.40 in

9.80 in

(W3P)

TPA-3005

17.70 in

(W6P)

9.40 in

TPA-3002

STANDARD RECOMMENDED PROCEDURE 003-499 | ISSUE 4 | SEPTEMBER 2015 | PAGE 3 OF 5

5. Opening the Wall-Mount unit

Both the provider and customer door are secured with

magnets. To open the door, pull on the ange at the top

of the cabinet.

6. Cable Sheath Removal

Perform cable sheath removal steps as

explained in the instructions for the cable

type you are installing. Suggested sheath

removal lengths are shown.

7. Cable Strain-relief and Grounding

Step 1: Pierce grommet at cable entry location.

Step 2: Feed cable through the grommet.

NOTE: Do not attach the bracket to the unit until you have performed the necessary steps to

strain-relieve the cable.

Step 3: Scrape paint off the base of the unit where the

cable strain-relief bracket will be installed.

Scrape paint off of the strain-relief bracket

also to ensure a good connection when the

bracket is installed on the unit.

Step 4: Attach the grounding bar (p/n

GROUND-KIT-1, ordered separately)

to the bracket in the location shown.

Step 5: Connect to the building ground

by using a ground wire to link the

grounding bar on the unit to the

building ground.

Strain-relieving Cable without Central Member

If the entire length of outside plant cable is routed within

an environmentally controlled building (where temperature

uctuation is minimal), strain-relieving the cable sheath with

the Universal Cable Clamp (UCC) is adequate.

Step 1: Install the cable into the clamp per the instruction

provided with the UCC kit.

Step 2: Attach bracket to the housing using the 6-32

screws provided. Slide grommet into position.

TPA-3008

Flange

Central Member:

10 cm (4 in)

Yarn: 20 cm (8 in)

Buffer Tube to Tray:

Top Entry - 140 cm (55 in)

Bottom Entry - 114 cm (45 in)

Fiber Length Inside Tray Per

Tray Instructions

TPA-3000

Ground bar

TPA-3011

TPA-3013

STANDARD RECOMMENDED PROCEDURE 003-499 | ISSUE 4 | SEPTEMBER 2015 | PAGE 4 OF 5

Strain-relieving Cable with Central Member

If you are terminating an outside plant cable or temperatures uctuate widely along any part of

the cable, the strength members should be secured. Failing to do so may result in damage to

the cable as temperatures vary.

Step 1: Attach the cable to the bracket (with cable ties in two

places).

Step 2: Install the 8-32x5/8-inch screw from the front side of

the strain-relief bracket through the at washer and

U-shaped washer. Loosely install the hex nut.

Step 3: Wrap the strength member yarn in a clockwise direction

around the screw and under the U-shaped washer.

Step 4: Insert the central member of the cable between the at

washer and the U-shaped washer.

Step 5: Tighten the hex nut.

Step 6: If the central member is metallic, place the eye of a

ground wire (#6 AWG, purchased separately in

appropriate length from any electrical supply store)

under the U-shaped washer or under the at washer.

NOTE: The ground wire must have metal-to-metal contact

providing an electrical path to the central member in order

to properly ground the cable.

Step 7: Attach the other end of the ground wire to the

building ground.

Step 8: Trim off the excess yarn and central member.

NOTE: The exposed length of the central member (after strain-

relief) is to be less than or equal to 6.5 cm (2 1/2 inches)

between the U-shaped washer and the end of the cable

sheath.

Step 9: Attach the bracket to the housing using the

6-32 screws provided. Slide grommet in position.

NOTE: Make sure the cable does not bend excessively as it enters the housing.

8. Buffer Tube Fan-out

Step 1: If using buffer tube fan-out kits (ordered separately)

to transition from buffer tubes to single bers, follow

the instructions provided with the kits.

Step 2: Secure the fan-out bodies to the buffer tube fan-out

bracket using a cable tie.

Step 3: Fasten the bracket to the housing using (2) lock

nuts.

9. Splicing to Pigtails

Step 1: Provide cable slack in the slack storage area.

Step 2: Install pigtail connectors.

Step 3: Label both the cable components and the pigtails with identication tags.

TPA-3009

TPA-3007

DA NG E R

TPA-3012

STANDARD RECOMMENDED PROCEDURE 003-499 | ISSUE 4 | SEPTEMBER 2015 | PAGE 5 OF 5

Corning Optical Communications LLC • PO Box 489 • Hickory, NC 28603-0489 USA

800-743-2675 • FAX: 828-325-5060 • International: +1-828-901-5000 • www.corning.com/opcomm

Corning Optical Communications reserves the right to improve, enhance, and modify the features and specications of Corning Optical Communications products

without prior notication. A complete listing of the trademarks of Corning Optical Communications is available at www.corning.com/opcomm/trademarks. All other

trademarks are the properties of their respective owners. Corning Optical Communications is ISO 9001 certied. © 2010, 2015 Corning Optical Communications.

All rights reserved.

Step 4: Route the cable and pigtails to an appropriate splicing

surface and perform steps as described in the

instructions for the splice tray and splicing method you

are using.

Step 5: Once splicing is complete, route cable slack around

the plastic retaining guides inside the storage area and

secure the splice tray into the unit using the retainer

bracket.

10. Cable Routing

Step 1: Install connectors onto the bers as per

manufacturing instructions, if nessessary.

Step 2: Route the bers inside the housing using the

routing pattern shown, ensuring a minimum

bend radius is maintained.

Step 3: Clean adapters annd connectors per standard

company practices. Mate connectors in the

adapters.

NOTE: A cable tie and anchor can be used to secure the bers as

needed.

11. Jumper Installation

Route the jumpers into the unit through either top or bottom holes

in the customer compartment and secure to the strain-relief bracket

using cable ties or the UCC.

12. Door Lock Installation

Step 1: Remove the double-D knockout from the appropriate door.

Step 2: Using the locking kit (p/n HDWR-LOCK-KIT), assemble

the components in the orientation shown.

TPA-3001

TPA-3003

Tie

wrap

anchor

TPA-3006

TPA-3004

Table of contents

Other CORNING Rack & Stand manuals