CAT125 2 11/21/14

FAILURE TO OBSERVE THESE WARNINGS COULD RE SULT IN IN JU RY.

THIS INSTRUCTION MANUAL CONTAINS

IMPORTANT SAFETY INFORMATION.

READ THIS INSTRUCTION MANUAL CAREFULLY

AND UNDERSTAND ALL INFORMATION BEFORE

OPERATING THIS TOOL.

• Itistheresponsibilityoftheownertomakesureall

personnelreadthismanualpriortousingthisairtool.

Itisalsotheresponsibilityoftheairtoolownertokeep

thismanualintactandinaconvenientlocationforall

toseeandread.Ifthemanualorproductlabelsarelost

ornotlegible,contactCornwellforreplacements.Ifthe

operatorisnotfluentinEnglish,theproductandsafety

instructionsshallbereadtoanddiscussedwiththe

operatorintheoperator'snativelanguagebythe

purchaser/ownerorhisdesignee,makingsurethat

theoperatorcomprehendsitscontents.

• Alwaysoperate,inspectandmaintainthistoolin

accordancewithAmericanNationalStandards

InstituteSafetyCodeofPortableAirTools(ANSIB186.1)

andanyotherapplicablesafetycodesandregulations.

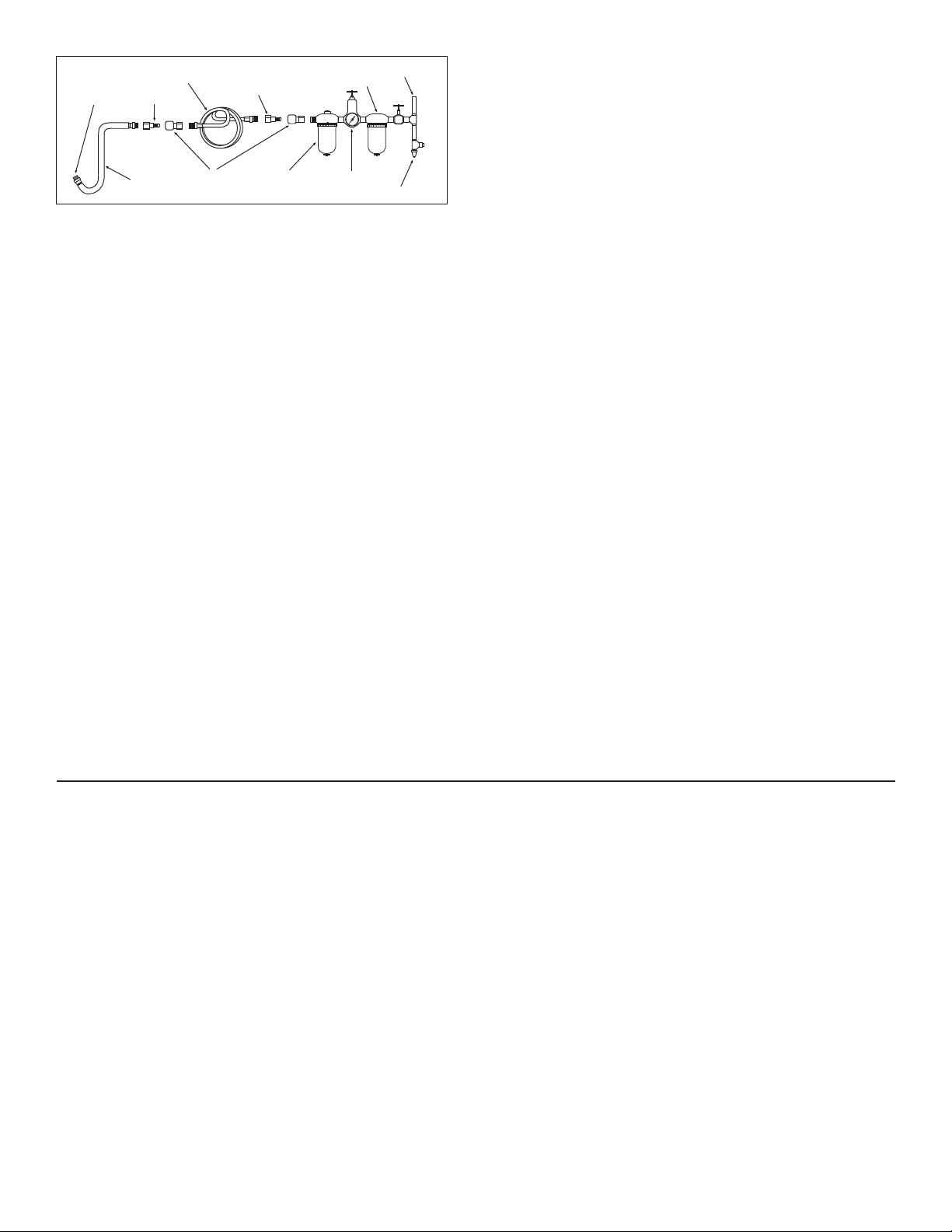

• Forsafety,topperformanceandmaximumdurability

ofparts,operatethistoolat90psig:6.2barmaxair

pressurewith3/8"diameterairsupplyhose.

• Alwayswearimpact-resistanteyeandface

protectionwhenoperatingorperforming

maintenanceonthistool(usersandbystanders).

• Alwayswearhearingprotectionwhenusingthistool

(usersandbystanders).Highsoundlevelscancause

permanenthearingloss.Usehearingprotectionas

recommendedbyyouremployerorOSHAregulation.

• Operatorsandmaintenancepersonnelmustbe

physicallyabletohandlethebulk,weightandpower

ofthistool.

• Operationcancauseimpacts,cuts,abrasionsandheat.

Wearglovestoprotecthands.

• Keepthetoolinefficientoperatingcondition.

• Airunderpressurecancausesevereinjury.Never

directairatyourselforothers.Alwaysturnofftheair

supply,drainhoseofairpressureanddetachtoolfrom

airsupplybeforeinstalling,removingoradjustingany

accessoryonthistool,orbeforeperformingany

maintenanceonthistool.Failuretodosocouldresult

ininjury.Whiphosescancauseseriousinjury.Always

checkfordamaged,frayedorloosehosesandfittings,

andreplaceimmediately.Donotusequickdetach

couplingsattool.Seeinstructionsforcorrectset-up

onpage4.

• Airpoweredtoolscanvibrateduringuse.Vibration,

repetitivemotionsoruncomfortablepositionsover

extendedperiodsoftimemaybeharmfultoyour

handsandarms.Discontinueuseoftoolifdiscomfort,

tinglingfeelingorpainoccurs.Seekmedicaladvice

beforeresuminguse.

• Slipping,trippingand/orfallingwhileoperatingairtools

canbeamajorcauseofseriousinjuryordeath.Beaware

ofexcesshoseleftonthewalkingorworksurface.

• Keepbodyworkingstancebalancedandfirm.

Donotoverreachwhenoperatingthetool.

• Anticipateandbealertforsuddenchangesinmotion

duringstartupandoperationofanypowertool.

• Donotcarrytoolbythehose.Protectthehose

fromsharpobjectsandheat.

• Toolshaftmaycontinuetoreciprocatebrieflyafterthrottle

isreleased.Avoiddirectcontactwithaccessoriesduring

andafteruse.Gloveswillreducetheriskofcutsorburns.

• Keepawayfromreciprocatingendoftool.Donotwear

jewelryorlooseclothing.Securelonghair.Scalping

canoccurifhairisnotkeptawayfromtooland

accessories.Chokingcanoccurifneckwearisnot

keptawayfromtoolandaccessories.

• Donotuse(ormodify)thetoolforanyotherpurpose

thanthatforwhichitwasdesignedwithoutconsulting

themanufacturer'sauthorizedrepresentative.

• Neveroperatetooluntilinspectedandconfirmedneedles

areproperlysecuredinthetool.

• Ensuretheworkpieceissecurelyfixed.

• Donotlubricatetoolswithflammableorvolatile

liquidssuchaskerosene,dieselorjetfuel.

• Thistoolisnotinsulatedagainstelectricshock.

• Thistoolmustnotbeusedinexplosiveatmospheres.

• Servicingandrepairsshouldonlybemadebyan

authorizedservicecenter.

• Donotforcetoolbeyonditsratedcapacity.

• RPM of the accessory must exceed tool RPM.

• Use accessories rated at 4,500 BPM or more.

• Use accessories recommended by Cornwell Tools.

• Never use dull, chipped or damaged accessories.

Nevercoolahotaccessoryinwaterasbrittlenessand

earlyfailurecanresult.Accessorybreakageortool

damagemayresultfromprying.Takesmallerbitesto

avoidgettingstuck.

the "on" position, as the lever must be free to return

to the "off" position when released.

• Keeptooloutofreachofchildren.

• Donotremoveanylabels.Replaceanydamagedlabels.

• Thisproductmaycontainoneormorechemicalsknown

totheStateofCaliforniatocausecancerandbirthdefects

orotherreproductiveharm.Wash hands thoroughly after

handling.

RPMRPMRPM