31 of 109

CORRADI S.P.A. - USER MANUAL - EXYL

2 - 04.2011

ITALIANO

DEUTSCH

FRANÇAIS

ESPAÑOL ENGLISH

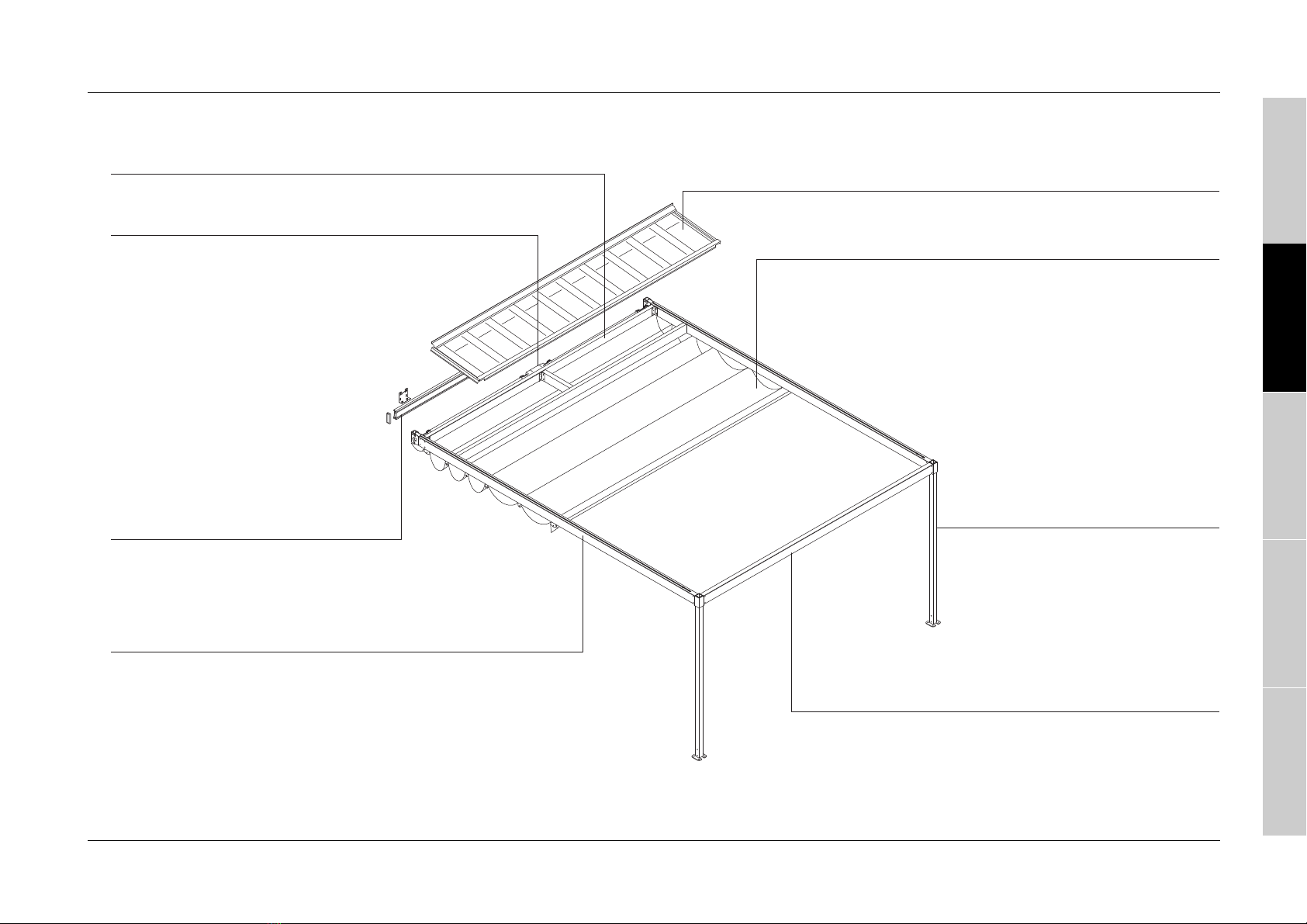

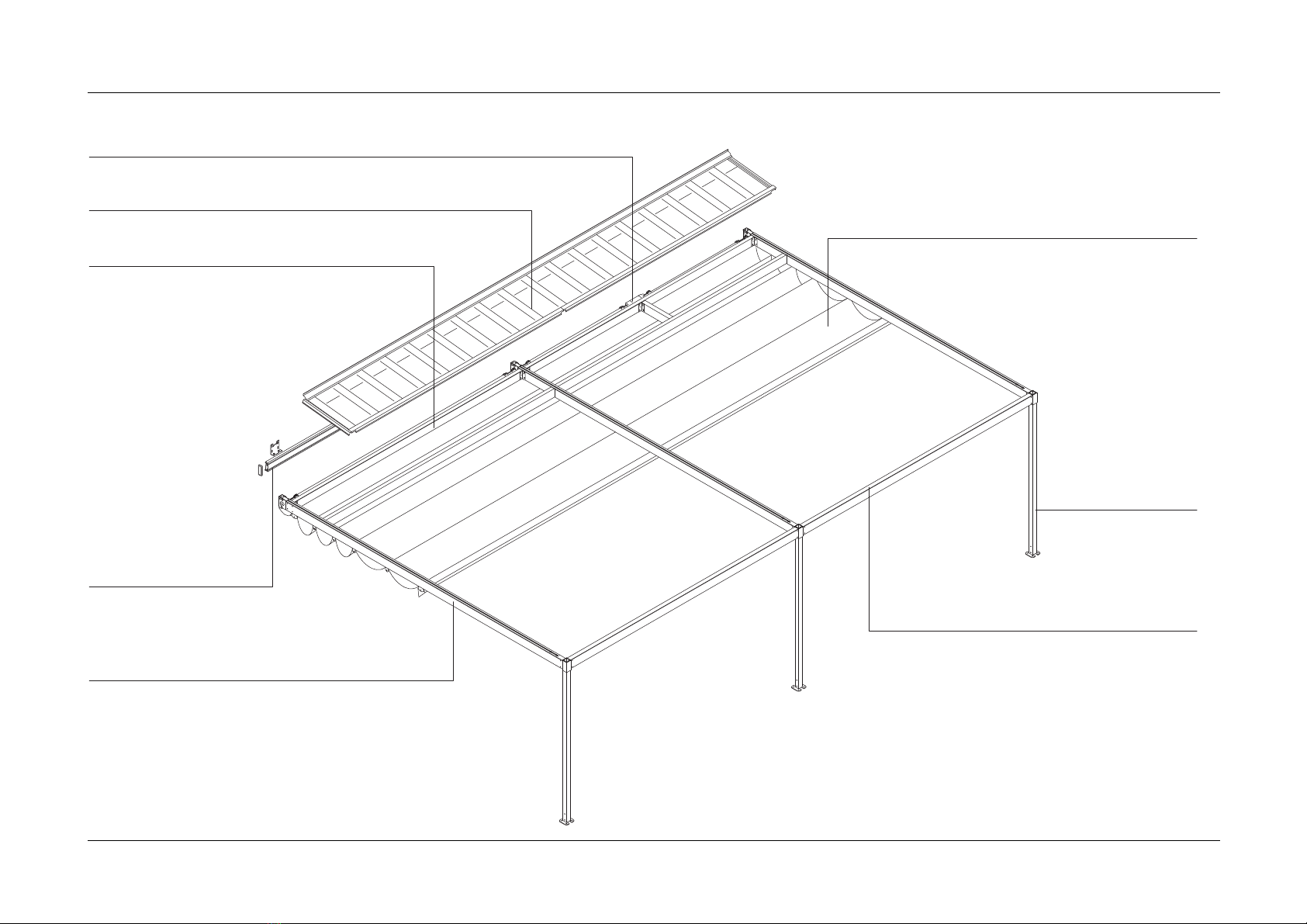

PRODUCTSFEATURES

PRODUCT FEATURES NON COMPLIANCE/ DEFAULT WARNINGS

GENERAL

Defaults have to be reported within 8 days starting on

installation date on the customer's site (point of reference is

the date indicated on the declaration of correct installation

issued to the end user by the installer). See general sales

term.

The structure is not watertight. In case of particularly violent storms with strong winds

water seepage may occur.

In case wind values should exceed those shown on the statement of correct installation, it

is necessary to close the awning. It is possible to use a properly calibrated anemometer.

The product does not guarantee the snow load. In presence of snow, even of low

intensity, the canvas should be closed.

To have your product warranty the certificate of proper installation is MANDATORY. A copy

must be given to the final customer and a copy shall be sent to Corradi SpA.The

reception of the duly completed certificate will activate the product warranty.

Any change to the product not expressly authorized by Corradi SpA leads to loss of war-

ranty.

The structures that are located in an urban environment are subject to pollutants (smog,

acid rain), smoke from chimneys, fumes from cooking, and weather in general. It is normal

for the fabric and the structure to get dirty.The structures and the fabric are NOT self-

cleaning.

SELF-SUP-

PORTING

By applying a lateral load on the pillar an oscillation in the structure may occur.This

movement is not a sign of structural weakness, but is considered normal for the type of

structure.The structure has been calculated by qualified engineers using the Eurocodes

and is guaranteed to wind up to the level indicated in the EC certificate and in the

Declaration of correct installation.

CANVAS Depending on the installation conditions, it is possible that the cloth gets dirty (pollutants,

smoke from chimneys, smog, etc.). In this case it may be necessary to clean the fabric

more frequently as indicated in the section maintenance.

The cloth is not immune from burns caused by cigarette butts, etc..

In particular situations of use of the structure, condensation may occur on the inside of

the fabric.To limit this condition proceed with an adequate ventilation of the room.

The appearance of mold in the embossing of the fabric is due to the presence of moisture

on the sheet that favores the formation of micro-organisms. It is therefore necessary to

clean the fabric at regular intervals, more frequently if necessary.

The presence of folds on the fabric after the first installation may be due to packaging. It is

necessary to keep the fabric in position for at least 10 days, and evaluate the quality of the

product after this period of time.

The presence of folds on the fabric after 10 days has to

be considered a default.