Safety information

This device is not intended for use by persons with reduced physical, mental or sensory impairments

nor other persons lacking the necessary skills or experience, unless supervised or instructed by

another person with responsibility for their safety.

Children may only use the device under the supervision of an adult to

ensure that the device is not used as a toy.

Electrical installations carried out in connection with the drier installation must be performed by a

professional in accordance with local and national regulations.

In addition, the following warnings and instructions must be read and followed:

1. The drier is only intended for indoor use.

2. The drier must not be powered on before installation is completed in accordance with this

manual.

3. The drier must not be covered because this may lead to overheating and fire.

4. The drier must not be used as a work table, trestle or stool.

5. The drier is not intended to be stood or climbed on.

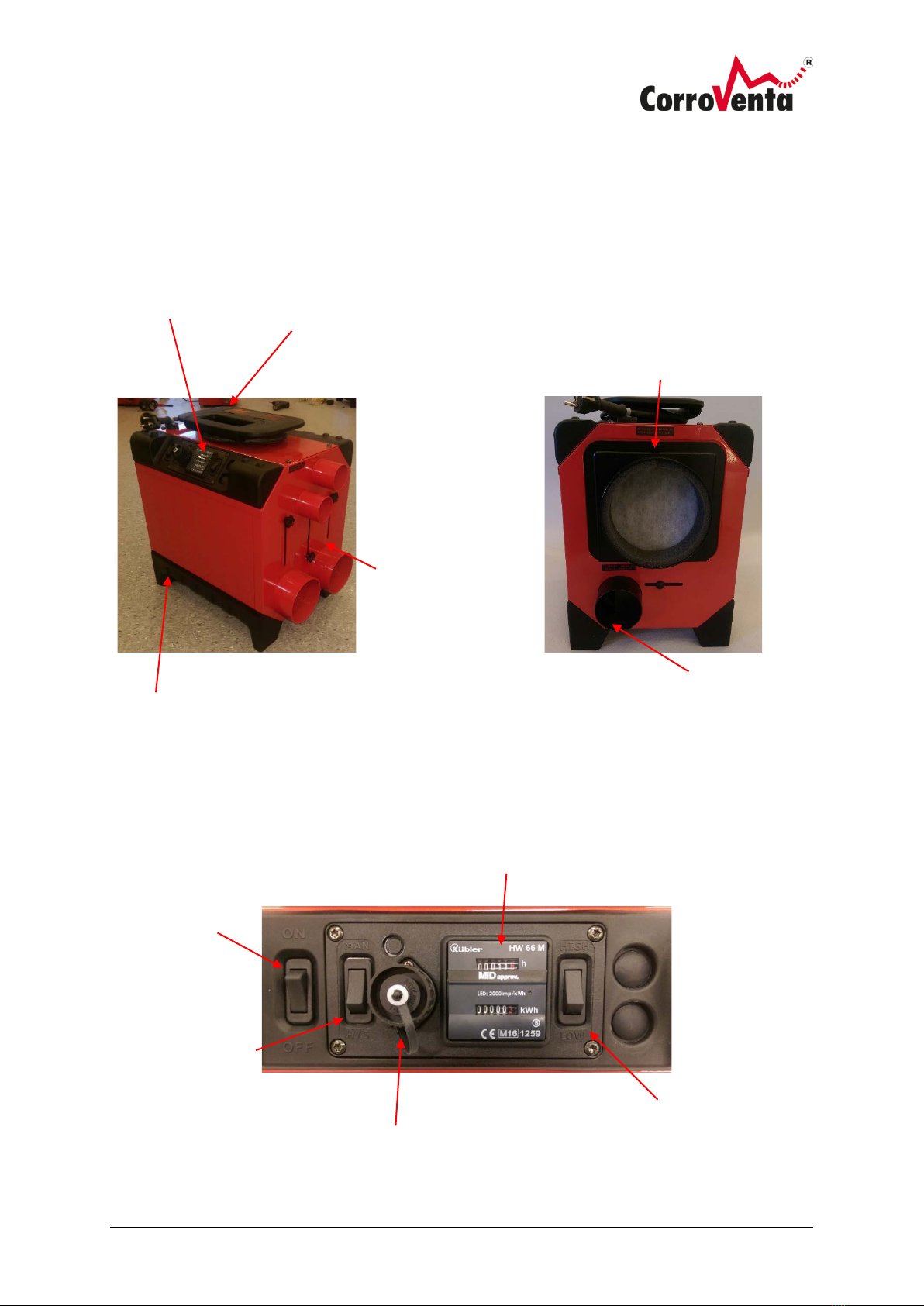

6. Never operate the drier without installing the filter as this may damage the drier. Ensure that

the filter is clean. If it is blocked, the machine may overheat.

7. Do not allow the drier to draw in alkaline chemicals or organic substances with a high boiling

point, such as oil, grease, solvents, boracol or similar. These can damage the rotor.

8. The drier may not be used in areas where it can produce explosive gases.

9. Do not insert objects into the intake or exhaust as this could damage the drier and injure

people.

10. Place the drier on a firm and flat surface so that it cannot overturn.

11. Keep children, animals and bystanders away from the workplace.

12. Contact the supplier if the drier is damaged or if the plug or the electrical cable are damaged.

Do not make any repairs yourself if you have not undergone the supplier's training.

13. Do not damage the electrical cable. The cable must not run through water or over sharp

edges.

14. Never carry or drag the drier by the cable.

15. Using electrical equipment in very damp or wet conditions can be dangerous. Do not operate

the drier if it is standing in water.

16. The drier may only be connected to a grounded socket with voltage according to the rating

plate.

17. It is recommended to use an earth-fault breaker to minimise the risk of electric shock.

18. Water must not come into contact with the drier's electrical components. If it does, ensure

that they are dried thoroughly before the drier is used again.

19. Never open the drier for cleaning or service without first ensuring that the drier is

disconnected from power.

20. Repairs and maintenance of the drier's electrical system must be performed by a qualified

electrician.

21. Wet air hoses/pipes used and connected to the drier must be corrosion resistant and able to

withstand heat of 80°C.

22. The drier must not be used with accessories other than those described in this manual or

approved by Corroventa Avfuktning AB.

Contact the supplier of this drier for further advice on the safety and use of the product.