SPX Hankison GCU Series User manual

GCU Series

Refrigerated Type Compressed Air Dryers

Models: GCU-0.5, GCU-0.75, GCU-1.0, GCU-1.5, GCU-2.0, GCU-2.5, GCU-3.5

FORM NO.: 5003343 REVISION: 04/2015 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

CONTENTS

GENERAL SAFETY INFORMATION............................................................................. 1

RECEIVING, MOVING, AND UNPACKING ................................................................. 1

1.0 INSTALLATION

1.1 Location ................................................................................................................... 2

1.2 Mounting .................................................................................................................. 3

1.3 Piping Connections .................................................................................................. 3

1.4 Electrical Connections............................................................................................... 3

1.5 Moisture Separator .................................................................................................. 3

1.6 EDD Operation........................................................................................................... 3

2.0 OPERATION

2.1 Minimum/Maximum Operating Conditions ............................................................. 4

2.2 Start-up ..................................................................................................................... 4

2.3 Using the RS-485 Port Connector (J8) ..................................................................... 6

2.4 Using the USB Host Feature (J7)............................................................................... 7

2.5 Using the Ethernet Feature (J3) ............................................................................... 8

3.0 MAINTENANCE

3.1 Daily ........................................................................................................................... 14

3.2 Weekly ....................................................................................................................... 14

3.3 Monthly ..................................................................................................................... 14

3.4 Annually ..................................................................................................................... 14

4.0 TROUBLESHOOTING GUIDE

Models 0.5 & 0.75...................................................................................................... 15

Models 1.0 – 3.5 ........................................................................................................ 16

5.0 REFERENCE

Sizing ......................................................................................................................... 17

Engineering Data....................................................................................................... 18

Dryer Set Point Table................................................................................................. 19

Dryer Alarm Table ...................................................................................................... 20

Controller Screen Shots

Status Menu Screens............................................................................................. 21

Setup Menu Screens ............................................................................................. 22

Network Menu Screens......................................................................................... 23

6.0 WIRING DIAGRAMS

Model 0.5

:

120/230 VAC........................................................................................... 24

Model

0.75

: 120/230 VAC....................................................................................... 25

Models 1.0 – 2.5: 460 VAC........................................................................................ 26, 27

Model 3.5: 460 VAC .................................................................................................. 28, 29

Models 1.0 – 3.5: 575-460/3/60 Transformer Pack ................................................. 30

7.0 DIMENSIONS / WEIGHTS .................................................................................... 31

8.0 REPLACEMENT PARTS

Models 0.5 and 0.75 .................................................................................................. 32, 33

Models 1.0 through 3.5

Air-Cooled Units .................................................................................................... 34, 35

Water-Cooled Units ............................................................................................... 36, 37

Cabinet Panels (all models) ....................................................................................... 38

WARRANTY..................................................................................................................... 41

1

GENERAL SAFETY INFORMATION

1. PRESSURIZED DEVICES:

This equipment is a pressure containing

device.

• Donotexceedmaximumoperating

pressure as shown on equipment

serial number tag.

• Make sure equipment is depressurized before

working on or disassembling it for service.

2. ELECTRICAL:

This equipment requires electricity to

operate.

• Installequipmentincompliancewith

all applicable electrical codes.

• Standard equipment is supplied with electrical

enclosures not intended for installation in hazardous

environments.

• Disconnect power supply to equipment when

performing any electrical service work.

3. BREATHING AIR:

• Air treated by this equipment may

not be suitable for breathing without

further purification.

Refer to applicable standards and

specifications for the requirements

for breathing quality air.

RECEIVING, MOVING, AND UNPACKING

A. RECEIVING

This shipment has been thoroughly checked, packed and

inspectedbeforeleavingourplant.Itwasreceivedin

good condition by the carrier and was so acknowledged.

CheckforVisibleLossorDamage.Ifthisshipmentshows

evidence of loss or damage at time of delivery to you,

insist that a notation of this loss or damage be made on

the delivery receipt by the carrier’s agent.

B. UNPACKING

Check for Concealed Loss or Damage. When a shipment

has been delivered to you in apparent good order, but

concealed damage is found upon unpacking, notify the

carrier immediately and insist on his agent inspecting

the shipment. Concealed damage claims are not our

responsibility as our terms are F.O.B. point of shipment.

C. MOVING

Inmovingortransportingdryer,donottipdryeronto

its side.

D. STORAGE/SHUT DOWN

Dryer should not be stored outside (either

packed or unpacked) or exposed to the weather. Damage

to electrical and control components may result.

IMPORTANT: WATER-COOLED UNITS - If unit is shut down

below freezing temperatures, the water-cooled condenser

may freeze and cause permanent damage. Condenser must

be drained when the unit is shut down.

IMPORTANT: Do not store dryer in temperatures above

130°F (54.4°C).

2

IMPORTANT:READPRIORTOSTARTINGTHISEQUIPMENT

1.0 INSTALLATION

1.1 Location

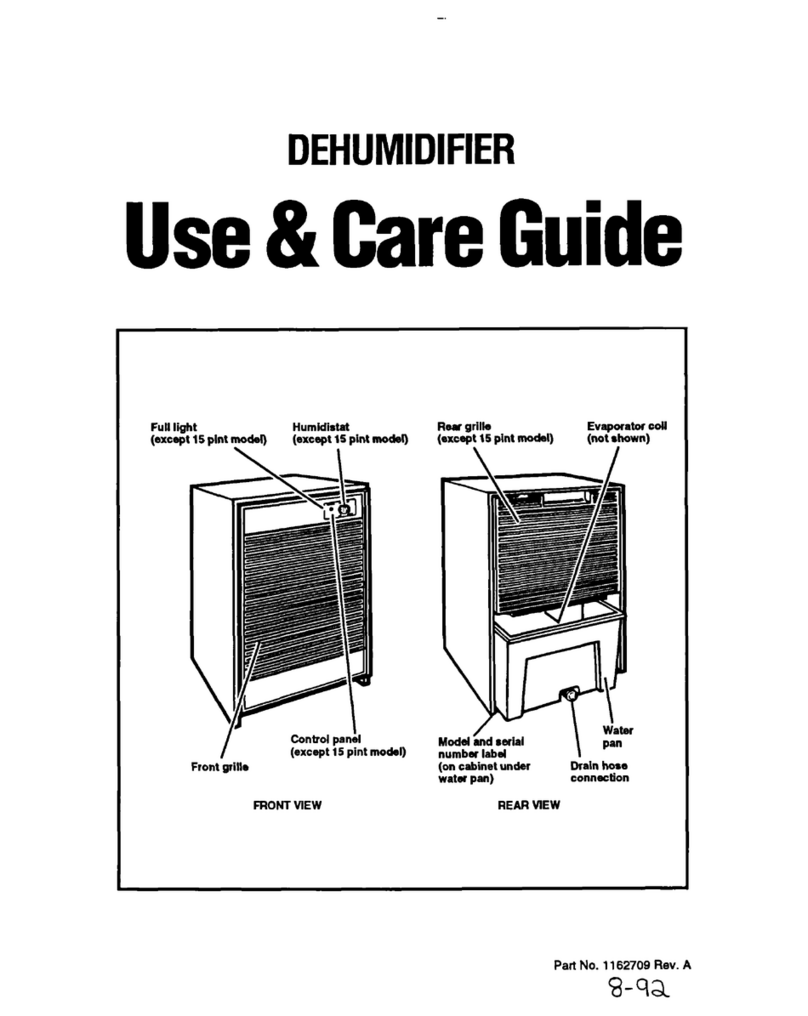

A. For typical placement in a compressed air system, see

drawing.

B. Air compressor intake – Locate air compressor so that

contaminants potentially harmful to the dryer (e.g.

ammonia) are not drawn into the air system.

C. Clearances Free air flow

Front 36 inches (914 mm)

Back 6 inches (152 mm)

Sides 36 inches (914 mm)

Service - To facilitate maintenance leave 36 inches

(914 mm) of clearance in front of dryer.

D. Standard units are designed to operate in ambients:

Air-cooled: 40 to 110°F (4.4 to 43°C).

Water-cooled: 40 to 130°F (4.4 to 54°C).

E. Installationsinaltitudesabove4500feet(1370meters)–

Dryer is adjusted to operate in altitudes up to 4500 feet

(1370meters).Ifdryerisinstalledinanaltitudeabove

this, and has not been preset at the factory for this

altitude, contact manufacturer’s Service Department.

F. The installation of a flexible connection prior to the

dryer is recommended to prevent possible damage from

vibration.

NOTE: Outdoor installation – Standard units are designed

for indoor installation. Contact manufacturer if installing

outdoors.

Aftercooler

Separator

Dryer

Oil Removal

Filter

Compressor

Electric Demand Drain (EDD)

3-Way Valve

Moisture Separator

Coalescing Filter

(Option)

Control Panel

Electrical Entry

Air Outlet

Air Inlet

Condenser

Drain Outlet

Models 1.0, 1.5, 2.0, 2.5, & 3.5Models 0.5 & 0.75

Moisture Separator

Coalescing Filter

(Option)

Float Drain

(Standard)

Condenser

Drain Outlet

Electrical Entry

(230 VAC)

Air Outlet

Air Inlet

Control Panel

3

1.2 Mounting

Mount the dryer on a level solid surface. Holes are provided

in the dryer base to permanently mount the dryer to the

floor.

1.3 Piping Connections

A. AirInlet-Connectcompressedairlinefromairsource

to air inlet. (Reference markings on dryer for air inlet/

outlet connection locations.)

Refer to Serial Number Tag for maximum

working pressure. Do not exceed dryer’s Maximum Working

Pressure.

NOTE:Installdryerinairsystemathighestpressurepossible

(e.g. before pressure reducing valves).

NOTE: Installdryeratcoolestcompressedairtemperature

possible. Maximum inlet compressed air temperature: 120°F

(49°C).Ifinletairexceedsthistemperature,precooltheair

with an aftercooler.

B. Air Outlet – Connect air outlet to downstream air lines.

C. Bypasspiping–Ifservicingthedryerwithoutinterrupting

the air supply is desired, piping should include inlet and

outlet valves and an air bypass valve.

D. Water cooled models – cooling water inlet and outlet

1. Connect cooling water supply to cooling water inlet.

2. Connect cooling water return line to cooling water

outlet connection.

NOTE: Strainer and water regulating valve are supplied on

water cooled models.

1.4 Electrical Connections

IMPORTANT:Usecoppersupplywiresonly.

A. Dryer is designed to operate on the

voltage, phase, and frequency listed on

the serial number tag.

B. Ifdryerissuppliedwithacordandplug,

install in a receptacle of proper voltage.

C. Electrical entry on larger dryers is through a hole in

thecabinet.Itislocatedontherightsidepanelwhen

facing the front of the unit. Connect power source to

terminal strip in electrical enclosure as shown on the

wiring diagram included with the dryer.

NOTE: Refrigeration condensing unit is designed to run

continuously and should NOT be wired to cycle on/off with

the air compressor.

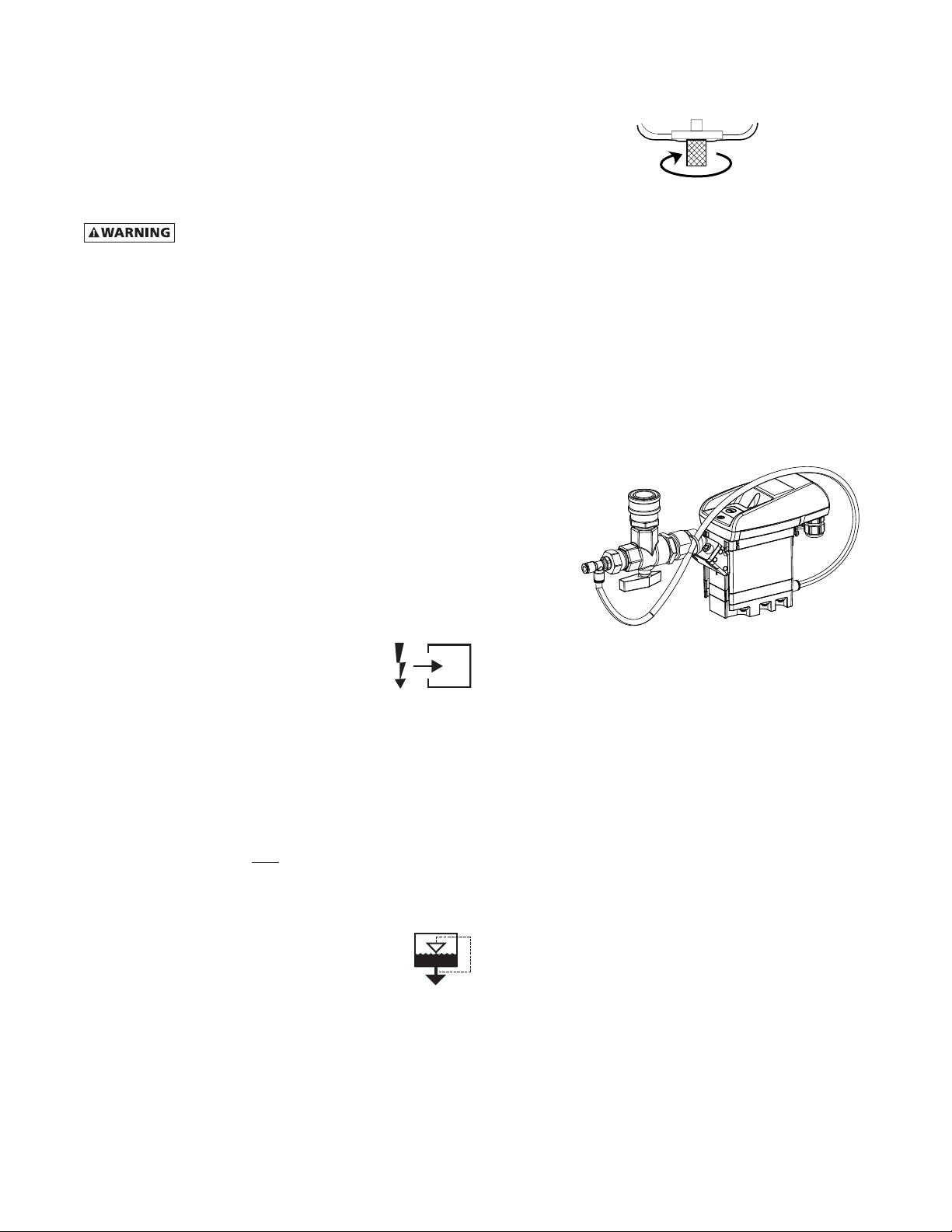

1.5 Moisture Separator

A. Models 0.5 & 0.75:

Separator (and Oil Removal Filter where

applicable) has an internal drain which

automatically discharges condensate.

Models 1.0 - 3.5:

Separator (and Oil Removal Filter where applicable) has

an electronic demand drain (EDD) which automatically

discharges condensate.

NOTE:Itmaybedesirabletopipethecondensatefromthe

Automatic Drain outlet to a suitable drain.

B. Models 0.5 & 0.75:

Separator has a knurled fitting with flexible drain tubing

attached. Be sure knurled fitting is tightened by turning

counter-clockwise before operating dryer.

TO CLOSE

TURN COUNTERCLOCKWISE

C. Models 1.0 - 3.5:

For manual draining, convenient dryer depressurization,

and EDD service, a three-way valve assembly has been

installed at the bottom of the moisture separator (and

cold coalescing filter where applicable). Review the

following for proper drain function:

• Automatic Draining - Valve handle should be

positioned parallel to the valve body (as shown),

with the arrow on the handle pointing toward the

EDD.Inthisposition,condensatewillowfromthe

bowl to the EDD.

• DrainIsolation(Shutdown) -Valvehandleshall be

turned perpendicular to the valve body (rotate 90°).

Inthisposition,condensateowisshutoff.

•

Manual Draining - Drain valve handle shall be rotated

slightly past the drain isolation position to allow

throttling through the valve for manual discharge

and depressurization.

• NOTE: The quick disconnect fitting allows removal

of the entire drain assembly. However, the unit

must be depressurized prior to disassembly or

serious injury may occur.

NOTE:Discharge is at system pressure. Drain line should be

anchored.

NOTE:Condensate may contain oil. Comply with applicable

laws concerning proper disposal.

1.6 EDD Operation

A. Verifythatisolationvalvesareopen.Ifthedrainfailsto

discharge after the valve is energized, the electronic

control circuit will repeatedly energize the valve in an

attempttoclearthedischargeport.If,after60seconds,

the drain still fails to discharge, the control circuit then

switchestothealarmmode.Inthismodethevalveis

de-energized and the red alarm light is activated on the

drain. The valve is then automatically energized every

80 seconds for 60 seconds. Check the drain operation.

Push drain (push-to-test) button on the drain or the

Electronic Controller (if equipped) to energize drain. A

flow of condensate and/or air should be present at the

drain outlet. The alarm mode automatically clears after

the drain returns to normal operation.

4

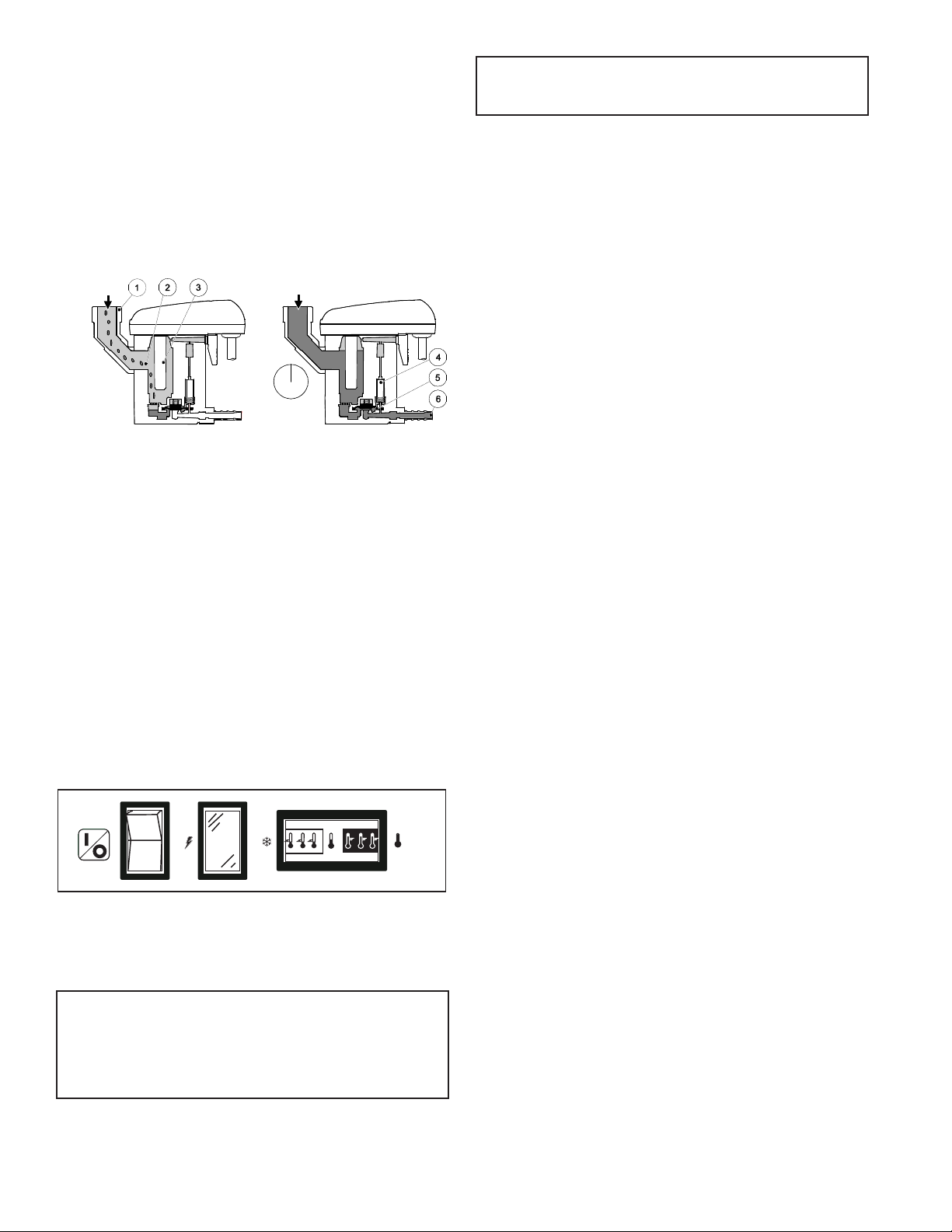

B. The condensate flows through the feed line (1) into

the condensate drain and accumulates in the housing

(2). A capacitive sensor (3) continuously registers the

liquid level. As soon as the container is filled, a fixed

waiting period begins during which more condensate

accumulates. After the waiting time has expired the

pilot valve (4) is then activated and the diaphragm

(5) opens the outlet line (6) for discharging the

condensate.

When the condensate drain has been emptied, the

outlet line is closed again quickly and tightly without

wasting compressed air.

NOTE: If there is no power to the control board for

a period of two weeks or more, it may return to the

default mode.

C. Program Monitor

Press and hold Program Mode button until Main Menu screen

appears. Use the Up and Down arrow buttons to scroll

through the list of submenu choices. Press Enter button

to view the submenu that is displayed. Press ESC to exit the

Main Menu and return to Display mode.

1. Language selection

a.

Use the ‘Up’ and ‘Down’ arrow buttons to scroll

through the list of languages (choice of 13 available:

English,Spanish,French,German,Portuguese,Italian,

Polish, Danish, Dutch, Norwegian, Finnish, Swedish

and Czech).

b. Press ‘Enter’ button to select the language that is

displayed.

c. Push ‘ESC’ at any time to return to the Main

Menu.

2. Setting Date & Time

a. Press ‘Enter’ to edit value.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set year

(00 to 99 representing 2000 to 2099). Press ‘Enter’

to accept new value.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set month

(1-12). Press ‘Enter’ to accept new value.

d. Use the ‘Up’ and ‘Down’ arrow buttons to set day

(01 to maximum for the month and year selected).

Press ‘Enter’ to accept new value.

e. Use the ‘Up’ and ‘Down’ arrow buttons to set hours

(00 to 23). Press ‘Enter’ to accept new value.

f. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes

(00 to 59). Press ‘Enter’ to accept new value.

g. Press ‘Enter’ to accept new value. Push ‘ESC’ at any

time to return to the Main

Menu.

3. Setting Schedule

a.

Use the ‘Up’ and ‘Down’ arrow buttons to select

desired “Day of week + on/off”. Press ‘Enter’ to

adjust time.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set hour

(00 to 23). Press ‘Enter’ to accept new value

NOTE:Ifthehoursettingis‘--:--’,Press‘Enter’again

to move the cursor under the “Day of week + on/

off”.

c. Use the Up and Down arrow buttons to set minutes

(00, 10, 20, 30, 40, 50; not shown if hour setting is

‘--:--’). Press ‘Enter’ to accept new value and return

to “Day of week + on/off”. Repeat steps a through

c as needed.

d. Push ‘ESC’ at any time to return to the Main

Menu.

4. Hours To Service

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll

through the range of permissible values (0 to 9999)

before service reminder is initiated. Press ‘Enter’

to move to next field. (Only hours that refrigeration

compressor is operating are counted).

2.0 OPERATION

2.1 Minimum/Maximum Operating Conditions

A. Maximum inlet air pressure: refer to dryer serial number

tag

B. Minimum inlet air pressure: 30 psig (2.1 kgf/cm

2

)

C. Maximum inlet air temperature: 120°F (49°C)

D. Maximum ambient temperature:

Air-cooled models: 110°F (43°C)

Water-cooled models: 130°F (54°C)

E. Minimum ambient temperature: 40°F (4.4°C)

2.2 Start-up

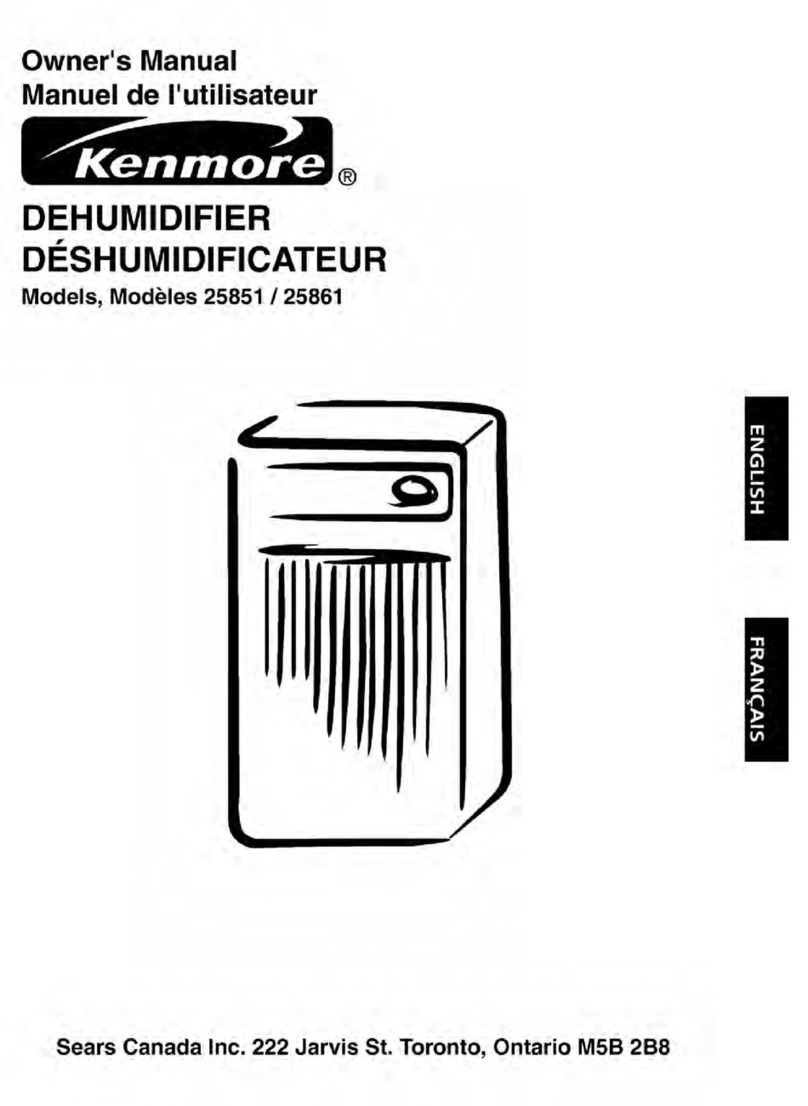

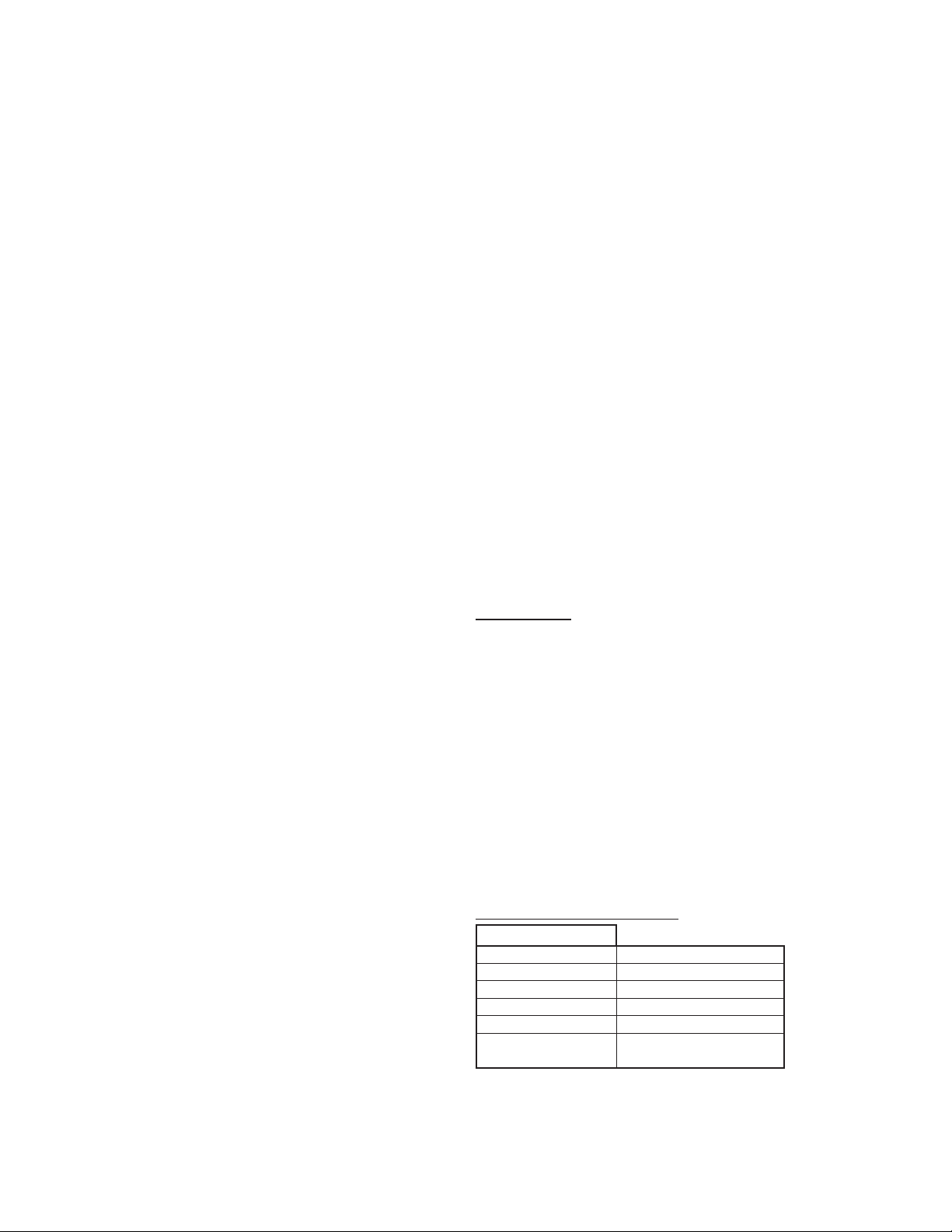

A. Models 0.5 & 0.75:

Energize compressor by positioning the on/off switch in

theon(I)position.Compressoronlightwillilluminate.

On/Off Power-On Dewpoint Indicator

Switch Light (Green)

B. Models 1.0 - 3.5:

Energizedryer.Greenpoweronlightwillilluminate.

IMPORTANT:Energizedryerdisconnectswitch(provided

by others, see NEC) 24 hours before refrigeration

compressor is started! Never use the disconnect switch

to shutdown the dryer for a extended period of time

(except for repair). Failure to follow these instructions

may result in a non-warrantable compressor failure.

5

b. Press ‘ESC’ at any time to return to the Main Menu.

NOTE: On dryers with air-cooled condensers, regular

condenser cleaning is recommended. Dirtiness

of ambient air at installation site will determine

frequency of service. Typically once a month is

recommended. Dryers contain an integral 3 micron

filter. As the filter element accumulates solid

contaminants, differential pressure increases. Solid

particulate load in the compressed air supply will

determine frequency of service. Typically element

changeout is recommended at least

annually.

5. Push ESC button to exit program mode.

6. Manual Operation

a. To manually turn the refrigeration system on or off

use ‘On/Off’ button; Push ‘Schedule On/Off and

Enter’ button to return to schedule.

NOTE: After power interruption dryer will reenergize

in Manual override, refrigeration system off. To

restart Schedule: Push ‘Schedule On/Off and Enter’

button.

D. Starting dryer

IMPORTANT: Dryer must be energized 24 hours before

starting refrigeration compressor.

NOTE:Itisrecommendedthatdryerbestarted15minutes

before compressed air flow begins.

1. On water-cooled models: after 24 hours, begin cooling

water flow.

2. Check for proper electrical voltage.

3. Slowly pressurize unit air side by opening inlet isolation

valve. Check for leaks.

4. After 15 minutes, open outlet isolation valve slowly.

5. Close air bypass valve.

6. Dryer may be operated in Manual or scheduled modes.

NOTE: Check for correct phasing of unit. On air-cooled

models: check fan rotation (air must be pulled through the

condenser). Fans may not start immediately or may cycle

onandoff.Ifrotationisinthewrongdirectionfollowthe

procedure below. On water-cooled models: After starting

dryer if an unusual noise is heard and the discharge line

does not get hot, stop the dryer, reverse two power leads,

restart, and verify discharge line gets hot.

Manual Mode - push On/Off button - refrigeration

compressor will start and run, green Compressor-on

lightwillilluminate.Inthismodecompressorwillrun

continuously and will not be turned on and off by the

monitor. MANUAL MODE will appear on interface panel.

Schedule Mode - push Schedule On/Off and Enter

button. SCHEDULED MODE will appear on the interface

panel. The compressor will then turn on or off as

programmed.

NOTE: Dryer may be returned to the Manual Mode at

any time using the ‘Schedule On/Off and Enter’ button

or by pressing On/Off button. MANUAL MODE will appear

on interface panel. To reinstitute Schedule, push the

‘Schedule On/Off and Enter’ button again.

NOTE: Restart after the power interruption. Unit will be in

MANUAL MODE mode, refrigeration compressor, off when

power is restored after power interruption.

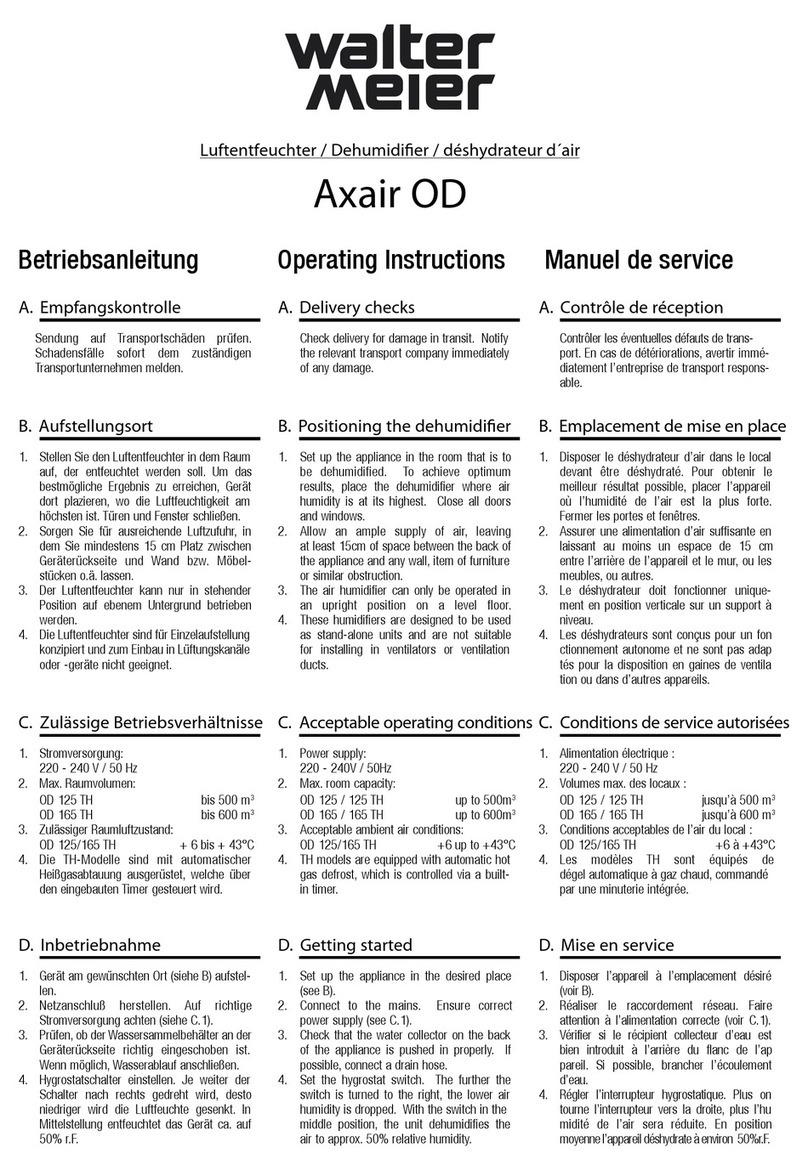

1. TemperatureIndicator

2. OperatorInterfaceDisplay

3. Power-on Light

4. Compressor-on Light

5. Alarm / Service Light

6. Schedule On/Off and Enter Button

a. InDisplay Mode: Press to toggle between

SCHEDULED MODE and MANUAL MODE.

b. InProgram Mode:

i. Press to move to a lower level menu.

ii. Press to accept a value that has been edited.

7. Program Mode (i) and Esc

a. InDisplay Mode: Press and hold to enter Pro-

gram Mode.

b. InProgram Mode: Press to move to a higher

level menu.

8. Up Arrow

a. InDisplay Mode: Press to cycle to next Display

screen

b. InProgram Mode:

i. Press to view the next item in a list or to

increment a variable to a higher value.

ii. When the top of the list (or highest value) is

displayed, pressing the up button will cause

the display to wrap to the bottom of the list

(or lowest value).

9. Down Arrow

a. InDisplay Mode: Press to cycle to previous Dis-

play screen

b. InProgram Mode:

i. Press to view the previous item in a list or to

decrement a variable to a lower value.

ii. When the bottom of the list (or lowest value)

is displayed, pressing the down button will

cause the display to wrap to the top of the

list (or highest value).

10. 1/0: Press at any time to turn the dryer on/off.

11. Drain test: Press at any time to momentarily open

the drains.

12. Reset: Press at any time to clear the alarm/service

message (if shown) and the alarm LED.

CONTROL PANEL

1 2 3 4 5

67 8 9 10 11 12

6

7. To reinstitute SCHEDULED MODE, push ‘Schedule On/Off

and Enter’ button.

IMPORTANT: Dryer must be energized 24 hours before

refrigeration compressor is started

E. Operating check points

1. Check that green Power-on light is illuminated

2. Check that green Compressor-on light is illuminated if

dryer is on in the manual mode or it is a scheduled on

time

IMPORTANT: Refrigeration compressor must be restarted

after power interruption.

3. Check interface panel

NOTE: Interface panel will scroll through three screens

(Current Time/Operating Status, Hours to Service and Total

Operating Hours).

a. Verify that current time is correct

b. CheckHRSTOSERVICE:thisindicatestimeremaining

until service is required; allow time for required

maintenance items to be ordered

c. Check operating status:

MANUAL MODE - Dryer is either running continuously

(not being controlled by the scheduled on/off times)

or the refrigeration compressor has been shut off

using the ‘On/Off’ button.

SCHEDULE MODE - Refrigeration compressor

is being turned on and off by the monitor per-

programmed schedule (see B.3. to set schedule).

d. Check Temperature indicator - indicator should read

in the green area.

e. Check Alarm/Service light If illuminated, check

Interfacepanel.

1) IfSERVICEDRYERappears,scheduledmaintenance

timehaselapsed(HRSTOSERVICEis0).Perform

needed service and reset service interval (see B.3.).

2)IfALARMappears,adryerfaultisindicated;see

Troubleshooting Guide for possible remedies.

After fault correction push Reset button to turn

Fault alarm off.

Type of FAULTS:

LOW PRESSURE - the refrigeration compressor

control circuit has opened because of low suction

pressure.

HIGH PRESSURE - the refrigeration compressor

control circuit has opened because of high head

pressure. The high pressure switch must be reset

manually once the fault is corrected. Red reset

button is located on pressure switch inside unit.

HIGHTEMPERATURE-compressedairtemperature

is above the set point.

COMPRESSOR - Normally open (NO) auxiliary

contact on the compressor contactor is open

when the dryer is on.

HEATER - Normally closed (NC) auxiliary contact

on the compressor contactor is open when the

dryer is off.

TEMP SENSOR - Occurs if the temperature

sensorcircuitisopenorshorted.Ifopen,none

of the LED’s in the temperature display will

be illuminated. If shorted, all the LEDs in the

temperature display will be illuminated.

DRAIN-electricdraincontainsahighwaterlevel

alarm that activates if drain fails to discharge.

f. Check drain operation - push Drain (push-to-

test) button to energize electric drain. A flow of

condensate and/or air should be present at the drain

outlet.

2.3 Using the RS-485 Port Connector (J8)

This connector provides RS-485 compatible signals from

the internal master microprocessor. Using jumpers on

the headers supplied near the connector (J12), 120 ohm

termination resistors can be connected and the system can

be connected for either two-wire or four-wire operation

(half or full duplex). To connect the termination resistors,

install jumpers on J12 in the direction shown by the white

bars printed above the connector.

IfthejumpersareremovednoterminationoftheRS-485

bus is in effect. Usually, these jumpers must be in position

for proper operation of the bus.

J10containsthetwo-wire/four-wirejumper.Ifthejumperis

setinW2place,thecircuitissetupfortwo-wireoperation.If

the jumper is set in W4 place, the circuit is set up for four-wire

operation. Selection of jumper settings must be determined

by the customer’s system. The jumpers are supplied as

standard and are installed as shown at the factory. Be sure

to set the jumpers properly for your system.

RS-485 Pinout

Following is the pinout for J8, the RS-485 communications

connector.

1 A

2 B

3 Z

4 Y

When connected in two-wire mode, the bus wires may be

connected to pins 1 & 2. Also note that when in two-wire mode,

one termination resistor jumper should be removed to prevent

theterminationfrombeingtoolowinvalue.Itmaybestored

on the top set of pins on J12. Those pins are not connected.

Please make sure that your connections are properly made. This

connector is a 4-pin terminal block. Mating connectors are not

supplied. The electrical signals supplied by this connector are

TIA/EIA-485Acompliant.Agoodcableshouldbeusedtotransmit

signals such as Belden 3109A or equivalent.

Communication Parameters:

RS-485 Parameters

Baud Rate 19200

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

ModbusDropI/O Factory Default = 1

(user adjustable 1 - 247 )

7

2.4 Using the USB Host Feature (J7)

The EMM connect is equipped with a USB Host port located

at J7 on the control board which allows for the connection

of a USB flash drive. The USB flash drive can be used for

data logging, event history, and installing software updates.

1. USB Data Logging

When a USB flash drive is installed in the controller it will begin

to automatically record key dryer operating parameters:

timestamp, dryer status, service timer, total compressor run

timer, discharge temperature, evaporator inlet temperature,

evaporator outlet temperature, and dryer % load.

These values will be written every 10 seconds to a comma

separated value file stored in the root folder of the USB

flash drive. Each day a new comma separated value file will

be created for storing the samples for that day. Comma

separated value files older than 60 days will be automatically

deleted.

2. USB Event History

When a USB flash drive is installed in the controller it will

begin to automatically log all dryer events: power loss,

power recovery, alarms, state (standby/running), and mode

(manual/scheduled/remote).

Events are timestamped and recorded in the EVENT.TXT file

stored in the root folder of the USB flash drive.

8

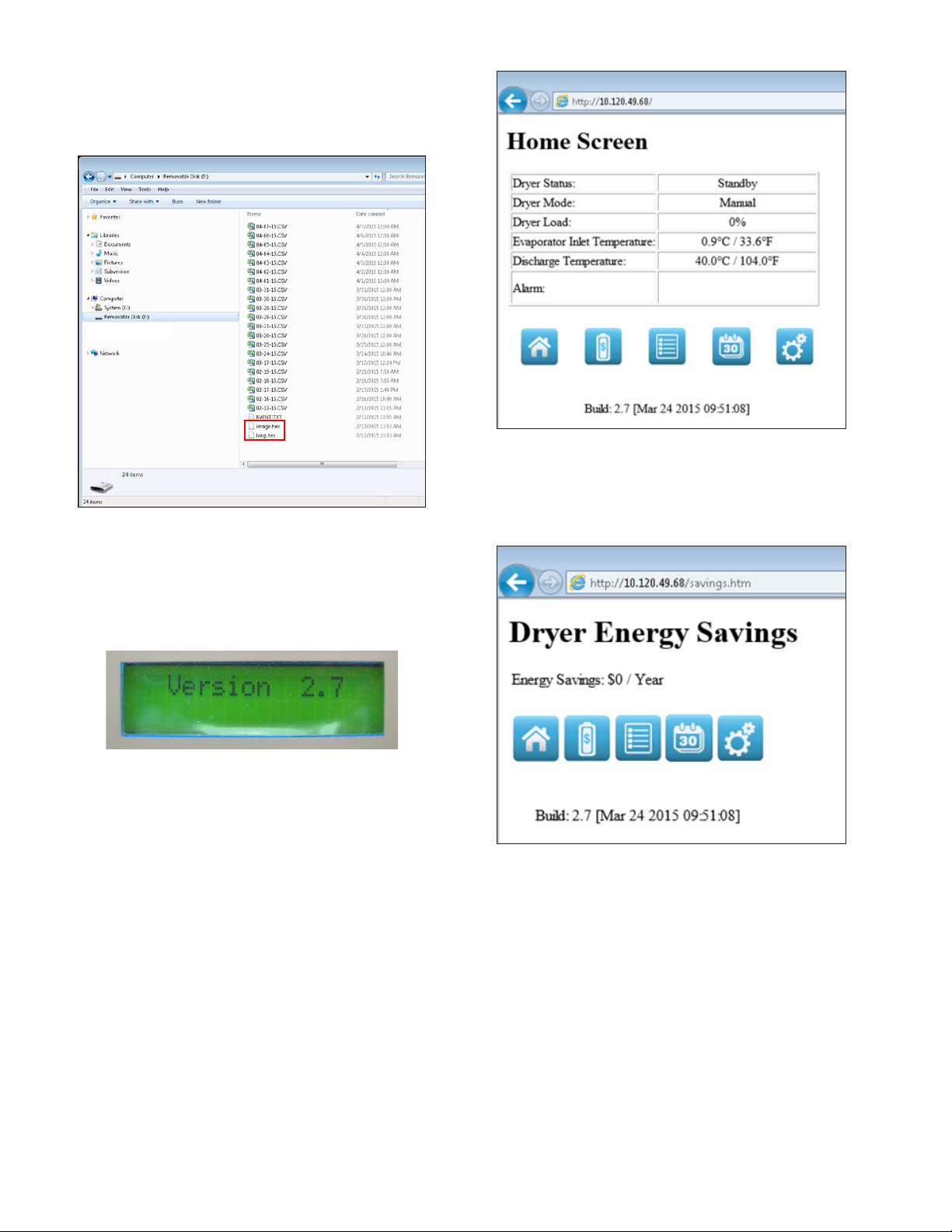

3. USB Bootloader

Firmware updates for the EMM connect can be performed via

theUSBashdrive.Inordertoperformarmwareupdate;

place the image.hex and lang.hex files provided by SPX in

the root folder of a USB thumb drive.

With the dryer controller powered off install the USB flash

drive in the USB host port on the EMM connect. Then while

holding the enter button on the front panel apply power to

the controller. Once the power LED begins blinking rapidly

you can release the enter button. The controller will reboot

when the update is complete. On startup the current

firmware version will be shown on the text display.

2.5 Using the Ethernet Feature (J3)

The EMM connect is equipped with an Ethernet port located

at J3 on the control board which allows the customer to

connect the dryer to a local area network. The customer

can then monitor the dryer status and performance via Web

InterfaceorModbusTCP.

1. WebInterface

After assigning an IP address to the dryer the IP address

can be entered into the address bar of any web browser to

connect to the web interface.

The first page displayed is the home screen. Displayed on

this page are the dryers operating status, operating mode,

current dryer load, evaporator inlet temperature, discharge

temperature, and any active alarms. The navigation bar at

the bottom of this page can be used to view energy savings,

event history, scheduler, and settings.

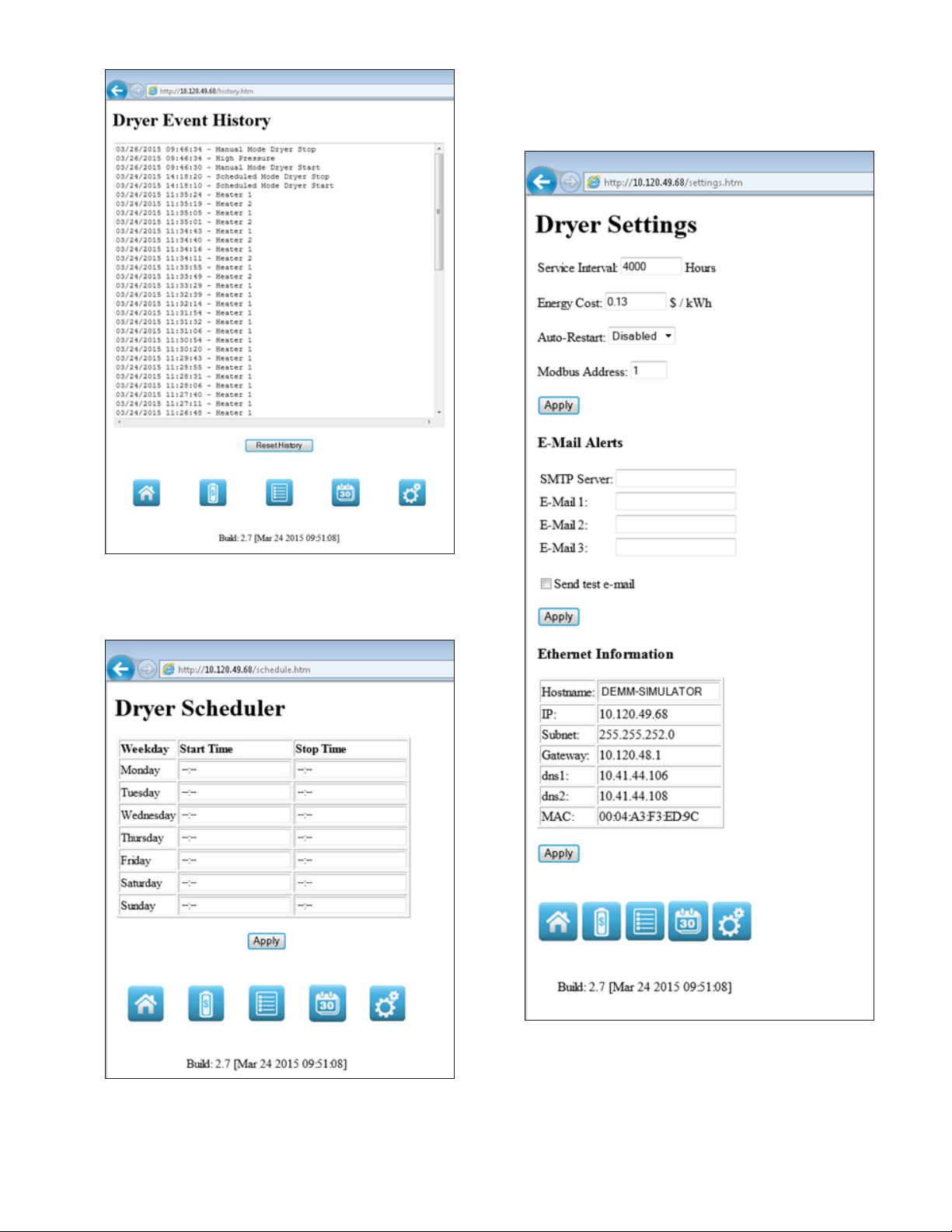

Figure 1: Home Screen

The energy savings page shows the estimated annual energy

savings based on your actual energy cost (entered on the

settings page) and the average dryer load over the last 30

days.

Figure 2: Energy Savings

The event history page shows the last 64 timestamped

events that have occurred on the dryer. These events include

power failure/recovery, dryer mode changes, dryer status

changes, and alarms.

9

Figure 3: Event History

The dryer scheduler page allows the customer to view/edit

the daily start/stop times that will be used when operating

the dryer in scheduled mode.

Figure 4: Schedule

The dryer settings screen allows the customer to view/edit

various dryer set points and setup E-mail alerts that will send

an e-mail to up to 3 different e-mail addresses whenever an

alarm or warning occurs on the dryer.

Figure 5: Settings

2. Modbus TCP

The Modbus TCP connection allows you to continuously

monitor the dryer from a DCS system which implements

a Modbus TCP master. The dryer controller implements

a ModbusTCP server on port 502. The following Modbus

register table provides a list of data that is available.

10

Modbus Registers

Holding Register

Reference Address Name Units Description

40001 0x0000 DRYER_STATUS StatusID StatusIDforthedryer

40002 0x0001 ALARM_STATUS Flag Bits Alarm flag bits

40003 0x0002 WARNING_STATUS Flag Bits Warning flag bits

40004 0x0003 RESERVED N/A Reserved

40005 0x0004 SERVICE_TIMER Hours Timer to service

40006 0x0005 TOTAL_TIMER Hours Total operating hours

40007 0x0006 EVAPORATOR_INLET_TEMP 1/10th Degree Celsius Evaporator inlet temperature

40008 0x0007 DISCHARGE_TEMP 1/10th Degree Celsius Discharge temperature

40009 0x0008 DRYER_LOAD % Dryer load

40010 0x0009 SAVINGS Dollars / Euros Energy savings

40011 0x000A EVAPORATOR_OUTLET_TEMP 1/10th Degree Celsius Evaporator outlet temperature

40012 0x000B

40013 0x000C

40014 0x000D

40015 0x000E

40016 0x000F

40017 0x0010 DRYER_MODEL Model_ID Dryer model

40018 0x0011 DRYER_MODE Mode_ID Dryer mode

40019 0x0012 SERVICE_INTERVAL Hours Service interval

40020 0x0013 AUTO_RESTART Boolean Auto-restart (0=Disabled, 1=Enabled)

40021 0x0014 UI_LANGUAGE Language_ID User interface language

40022 0x0015 RESERVED N/A Reserved

40023 0x0016 RESERVED N/A Reserved

40024 0x0017 ENERGY_COST Integer Energy cost (Cost / kWh)

40025 0x0018 AUDIBLE_ALARM Boolean Audible Alarm (0=Disabled, 1=Enabled)

40026 0x0019 MODBUS_ADDRESS Integer Modbus Address

40027 0x001A FULL_POWER Watts Full load power

40028 0x001B

40029 0x001C

40030 0x001D

40031 0x001E

40032 0x001F

40033 0x0020 ALARM_MSG_1 Integer Alarm message #1 phrase id

40034 0x0021 ALARM_MSG_2 Integer Alarm message #2 phrase id

40035 0x0022

40036 0x0023

40037 0x0024

40038 0x0025

40039 0x0026

40040 0x0027

40041 0x0028 INPUT_STATUS Flag Bits DigitalInputStatus

40042 0x0029 OUTPUT_STATUS Flag Bits Digital Output Status

40043 0x002A ANALOG[0] 1/10th Degree Celsius AnalogInput[0]

40044 0x002B ANALOG[1] 1/10th Degree Celsius AnalogInput[1]

40045 0x002C ANALOG[2] 1/10th Degree Celsius AnalogInput[2]

40046 0x002D PV 1/10th Degree Celsius Process value

40047 0x002E P Integer P Term

40048 0x002F I Integer ITerm

40049 0x0030 D Integer D Term

40050 0x0031 FIXED_LOAD Seconds Fixed cycle load period

40051 0x0032 FIXED_UNLOAD Seconds Fixed cycle unload period

40052 0x0033 FIXED_TIME Seconds Fixed mode timeout period

40053 0x0034 DELTA_PID_CALC 1/10th Degree Celsius PIDcalculationsetpoint

40054 0x0035 DELTA_PID_CTRL 1/10th Degree Celsius PIDcontrolsetpoint

11

Modbus Register Details

Page 1 of 3

Dryer Status

Register 40001

Decimal Hex Description

0 0x0000 Standby

1 0x0001 Fixed

2 0x0002 PID

3 0x0003 Reserved

4 0x0004 Reserved

5 0x0005 Reserved

6 0x0006 Reserved

7 0x0007 Reserved

Dryer Alarm Flags

Register 40002

Bit Mask Description

0 0x0001

High Discharge Temperature

1 0x0002 High Refrigerant Pressure

2 0x0004 Low Refrigerant Pressure

3 0x0008 Compressor #1

4 0x0010 Compressor #2

5 0x0020 Oil Protection #1

6 0x0040

Oil Protection #2

7

0x0080

Phase Reversal

8

0x0100

Phase Loss

9

0x0200

Evaporator Temperature Sensor Failure

10

0x0400

GlycolTemperatureSensorFailure

11

0x0800

Evaporator Outlet Temperature Sensor Failure

12

0x1000

Discharge Temperature Sensor failure

13

0x2000

High Super Heat

14

0x4000

Reserved

15

0x8000 Reserved

Dryer Warning Flags

Register 40003

Bit Mask Description

0 0x0001 High Evaporator Temperature

1 0x0002 HighGlycolTemperature

2 0x0004 Heater #1

3 0x0008 Heater #2

4 0x0010 Drain #1

5 0x0020

Drain #2

6 0x0040

Filter #1

7 0x0080

Filter #2

8 0x0100 Reserved

9 0x0200 Reserved

10 0x0400 Reserved

11 0x0800 Reserved

12 0x1000 Reserved

13 0x2000 Reserved

14 0x4000 Reserved

15 0x8000 Reserved

12

Modbus Register Details

Page 2 of 3

Dryer

Model

Register 40017

Decimal Hex Description

0 0x0000

Non-Cycling MRD

1 0x0001 Non-Cycling LRD

2 0x0002 ES-MRD 90

3

0x0003 ES-MRD

120

4

0x0004 ES-MRD 140

5

0x0005 ES-MRD

190

6

0x0006 ES-MRD

245

7

0x0007 ES-MRD

280

8

0x0008 ES-MRD

360

9

0x0009 ES-MRD

450

10

0x000A ES-MRD

540

11

0x000B ES-MRD

675

12

0x000C

DEMM 800

13

0x000D

DEMM 1000

14

0x000E

DEMM 1250

15

0x000F

DEMM 1500

16

0x0010

DEMM 1750

17

0x0011

DEMM 2000

18

0x0012

DEMM 2500

19

0x0013

DEMM 3000

20

0x0014

Reserved

21

0x0015

Reserved

22

0x0016

Reserved

23

0x0017

Reserved

24

0x0018

Reserved

25

0x0019

Reserved

26

0x001A

Reserved

27

0x001B

Reserved

28

0x001C

Reserved

29

0x001D

Reserved

30

0x001E

Reserved

31

0x001F

Reserved

Dryer Mode

Register(s) 40018

Decimal Hex Description

0 0x0000

Manual Mode

1 0x0001 Scheduled Mode

2 0x0002 Remote Mode

3 0x0003 Reserved

4 0x0004 Reserved

5 0x0005 Reserved

6 0x0006 Reserved

7

0x0007 Reserved

13

Modbus Register Details

Page 3 of 3

UILanguage

Register(s) 40021

Decimal Mask Description

0 0x0000

English

1 0x0001 Spanish

2 0x0002 French

3 0x0003 German

4 0x0004 Portuguese

5 0x0005 Italian

6 0x0006 Polish

7 0x0007 Danish

8 0x0008 Dutch

9 0x0009 Norwegian

10 0x000A Finnish

11 0x000B Swedish

12 0x000C Czech

13 0x000D Reserved

14 0x000E Reserved

15 0x000F Reserved

14

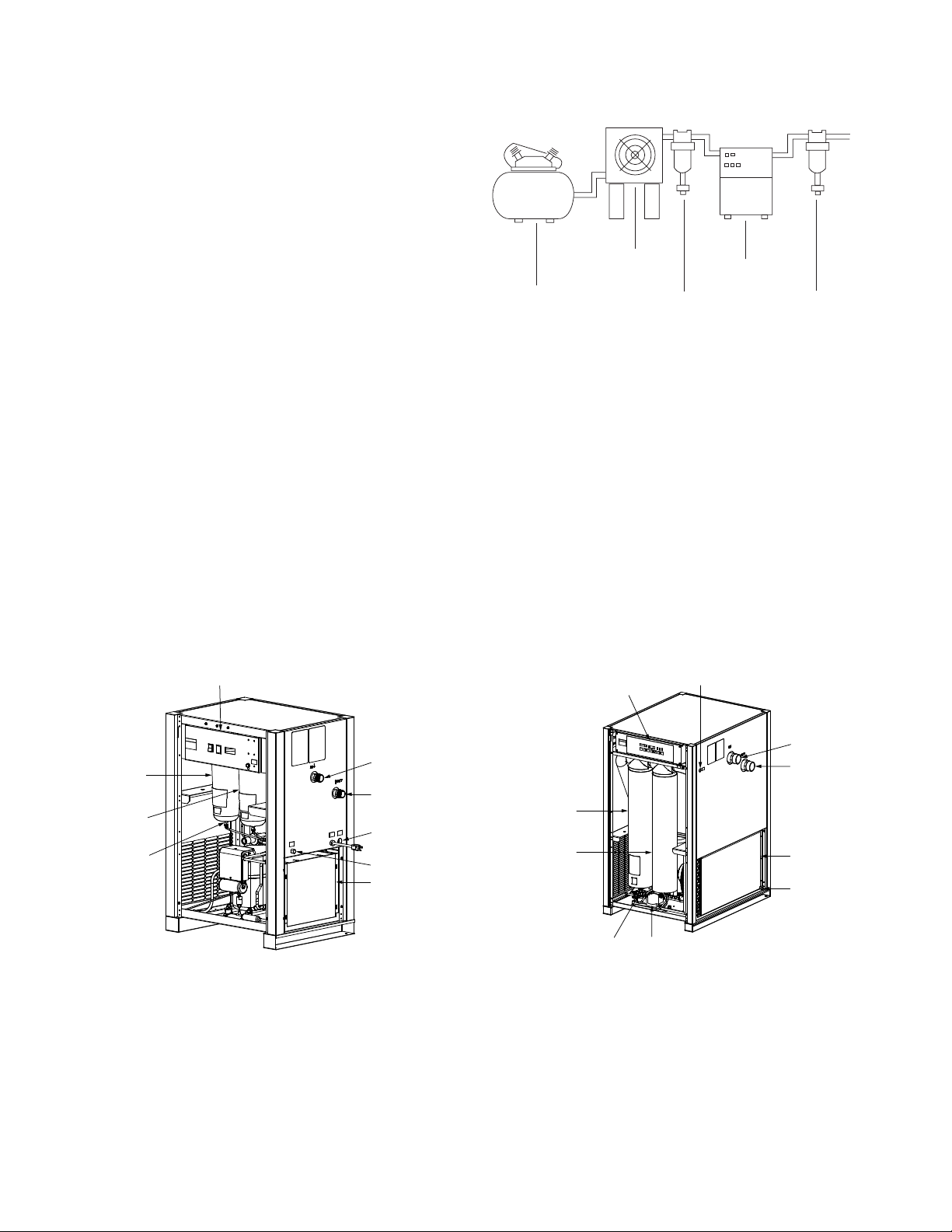

3.0 MAINTENANCE

3.1 Daily

A. Check separator to make sure the automatic drain is

discharging.

3.2 Weekly

A. Blow down the separator weekly by pushing the test

button on the control panel.

3.3 Monthly

A. Clean off the accumulated dust and dirt on the

condenser coil monthly.

3.4 Annually

A. Replace the filter element in the moisture separator

annually. Also replace the cold coalescing filter

element annually where applicable.

B. Replace the drain service unit annually.

C. Maintenance kits are available to facilitate annual

maintenance.

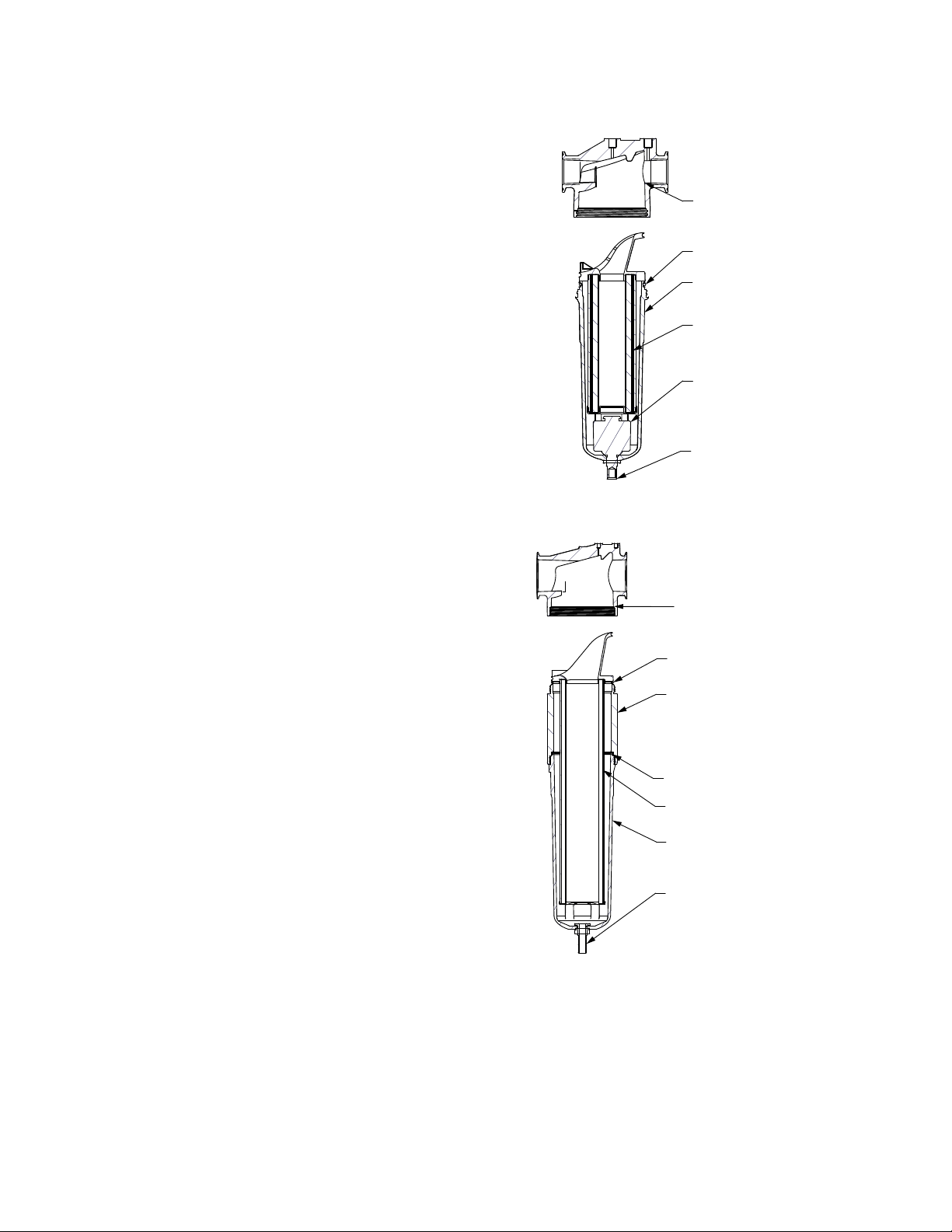

Models 0.5 & 0.75

Head

Bowl O-Ring

Bowl

Element

Float Drain

Drain Line

Connection

Models 1.0 – 3.5

Head

Extrusion O-Ring

(*Models 600-750 Only)

Extrusion

(*Models 600-750 Only)

Element

Bowl O-Ring

Bowl

Drain Connection

15

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

A) Water downstream of dryer 1. Residual free moisture remaining in

downstream pipelines

2. Air bypass system is open

3. InletandOutletconnectionsarereversed

4. Air lines downstream of dryer are exposed

to temperatures below the dew point.

5. Excessive free moisture (bulk liquid) at

dryer inlet.

6. Condensate not being drained

Drain mechanism is clogged or

inoperative.

7. Drain line is restricted or frozen.

8. Electric drains-timer not set to allow for

sufficient condensate removal.

9. Dryer overloaded resulting in elevated

dew point.

10. Refrigeration system not functioning

Blow out system with dry air

Check valve positions

Check for correct connection

Insulateorheattraceairlinesexposedtolow

ambients or dry air to lower dew point

Installseparatoraheadofdryer

Replace drain mechanism if inoperative.

Open drain line.

Electric drains-reset time so that all liquid is

discharged

Check inlet air temperature and pressure,

flow rate (compressor capacity) and ambient

air or water temperature.

See D below

B) High pressure drop across dryer 1. Excessive air flow

2. Freezing of moisture in evaporator

because of refrigeration system fault

3. Separator filter element clogged

Check flow rate

See D below

Replace filter element

C) Dew point indicator in red area 1. Dryer overloaded resulting in high air

outlet temperature

2. Refrigeration system not functioning

properly resulting in high air outlet

temperature

See A 7

See D below

D) Refrigeration system not

functioning properly

1. Power on light off

2. Refrigeration compressor cycles

on and off

a. Power failure

b. Line disconnect switch open

c. Blown fuses, open breaker

d. Faulty wiring, loose terminals

a. High or low ambient conditions

b. Air-cooled - Dirty, clogged condenser fins,

obstructed flow across condenser, faulty

fan motor or fan control switch.

Check for power to unit

Close disconnect switch

Check for continuity

Have electrician check electrical connections.

Check min./max. temperature ranges

Clean condenser and check for free air

flow, if problem persists contact qualified

refrigeration repairman or manufacturer’s

service department.

4.0 TROUBLESHOOTING GUIDE: MODELS 0.5 & 0.75

16

TROUBLESHOOTING GUIDE: MODELS 1.0 – 3.5

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

A) Water downstream of dryer 1. Residual free moisture remaining in

downstream pipelines

2. Air bypass system is open

3. InletandOutletconnectionsarereversed

4. Air lines downstream of dryer are exposed

to temperatures below the dew point.

5. Excessive free moisture (bulk liquid) at

dryer inlet.

6. Condensate not being drained

7. Dryer overloaded resulting in elevated

dew point.

8. Refrigeration system not functioning

1. Blow out system with dry air

2. Check valve positions

3. Check for correct connection

4. Insulateorheattraceairlinesexposedto

low ambients or dry air to lower dew point

5. Installseparatoraheadofdryer

6. See C below

7. See C below

8. See C below

B) High pressure drop across dryer 1. Excessive air flow

2. Freezing of moisture in evaporator

because of refrigeration system fault

3. Filter loaded with solid particulates

1. Check flow rate

2. See C below

3. Replace filter element

C) Checkpoint faults

1. Power on light off

2. Compressor on light off

3. Alarm/Service alert light on

-check Display for active

conditions

SERVICEDRYER

LOW PRESSURE

HIGHPRESSURE

NOTE:Ifhighrefrigerantpressure

occurs, switch must be manually

reset

HIGHTEMPERATURE

(also observed as high reading on

temperature indicator)

DRAIN

COMPRESSOR

HEATER

TEMP SENSOR

a. Power failure; open circuit

a. Compressor commanded off by manual

switch or programmed schedule

b. Open circuit

c. Control circuit open on high or low

pressure cutout

a. Service interval specified has elapsed

a. Hot gas bypass valve requires adjustment

b. Low on refrigerant

a. Lack of condenser cooling

Air-cooled - Ambient temperature too

high, clogged condenser fins, obstructed

flow across condenser, faulty fan motor or

fan control switch.

Water-cooled - Cooling temperature too

high, flow too low, clogged strainer, faulty

water regulating valve

a. Dryer overloaded

b. Refrigeration system off or not cooling

sufficiently

a. Drain line restricted or frozen

b. Drain mechanism faulty

a. Faulty compressor contactor.

b. Faulty N.O. auxiliary contact on

compressor contactor.

a. Faulty compressor contactor.

b. Faulty N.C. auxiliary contact on

compressor contactor.

a. Temperature sensor or wiring to sensor is

open (none of LED’s in the temperature

display will be illuminated).

b. Temperature sensor or wiring to sensor is

shorted (all of the LEDs in the temperature

display will be illuminated).

a. Check for power to dryer

a. Check current command status

b. Check power to compressor

c. Check display for fault

a. Perform scheduled service

a. Contact qualified technician or

manufacturer’s service department

Check air temperature 6” in front of

condenser; Clean condenser and check

for free air flow; Check fan and switch

operation

Check cooling medium temperature and

flow, clean strainer, check valve operation

a. Check compressed air flow, temperature,

and pressure

b. Check power to unit, power to

compressor, Low or High pressure faults

Have qualified technician evaluate system

a. Open drain line

b. Turn 3-way valve to horizontal position

and open petcock for manual draining.

Rebuild drain mechanism.

a. Check wiring and operation of contactor.

b. Check wiring and operation of auxiliary

contact.

a. Check wiring and operation of contactor.

b. Check wiring and operation of auxiliary

contact.

a. Replace sensor or repair wiring.

b. Replace sensor or repair wiring.

NOTE: After fault correction, press reset button to clear display

17

5.0 REFERENCE

SIZING

Determining dryer capacity at actual operating conditions

To determine the maximum inlet flow capacity of a dryer

at various operating conditions, multiply the rated capacity

from Table 1 by the multipliers shown in Table 2.

Example: How many scfm can an air-cooled model 1.5 handle

when compressed air to be dried is at 200 psig and 100°F;

ambient air temperature is 80°F?

Answer: 160 x 1.22 x 1.12 = 218 scfm.

TABLE 1

Rated capacity (scfm) and pressure drop @ 100 psig inlet

pressure, 100°F inlet temperature, and 100°F ambient

temperature

MODEL 0.5 0.75 1.0 1.5

Rated capacity

of air-cooled

models (scfm)

60 Hz

50 Hz

50

42

70

58

100

83

160

133

MODEL 2.0 2.5 3.5

Rated capacity

of air-cooled

models (scfm)

60 Hz

50 Hz

200

167

240

200

330

275

TABLE 2

Air capacity correction factors (Multipliers)

INLETCOMPRESSEDAIRCONDITIONS

INLET

PRESSURES

INLETTEMPERATURES

80°F 90°F 100°F 110°F 120°F

psig kgf/cm227°C 32°C 38°C 43°C 49°C

50

80

100

125

150

175

200

3.5

5.6

7.0

8.8

10.5

12.3

14.0

1.35

1.50

1.55

1.63

1.70

1.75

1.80

1.05

1.17

1.23

1.31

1.37

1.42

1.47

0.84

0.95

1.00

1.07

1.13

1.18

1.22

0.69

0.79

0.82

0.91

0.95

0.99

1.03

0.56

0.66

0.70

0.74

0.80

0.84

0.89

COOLINGMEDIUM*

AMBIENT

TEMPERATURE

MULTIPLIER

°F °C

80

90

100

110

27

32

38

43

1.12

1.06

1.00

0.94

*Air-cooled models; water-cooled models use 1.15 multiplier if cooling

water is below 35°C, 95°F.

18

ENGINEERING DATA

Models 0.5 0.75 1.0 1.5 2.0 2.5 3.5

Air System Data

Maximum / Minimum Inlet Air Pressure (compressed air at inlet to dryer) 232 psig (16 barg) / 30 psig (2 barg)

Maximum / Minimum Inlet Air Temperature (compressed air at inlet to dryer) 120°F (49°C) / 40°F (4.4°C)

Maximum / Minimum Ambient Temperature 110°F (43°C) / 40°F (4.4°C) Air-Cooled: 110°F (43°C) / 40°F (4.4°C) / Water-Cooled: 130°F (54°C) / 40°F (4.4°C)

Outlet Air Temperature (nominal at rated conditions) 40°F (4.4°C)

Refrigeration System Data

Refrigeration Capacity @ 35°F Evaporator & 100°F Ambient (BTU/hr) 60 Hz 4510 7130 8900 15200 19200 22000 30500

50 Hz 4600 7200 7420 12700 16000 18300 25400

Refrigerant Type R-134A

Refrigerant Charge See Data Tag on Dryer

Suction Pressure Setting - Hot Gas Bypass Valve (psig) 30.5 psig (2.1 barg)

Compressor Control Ranges (out-in) High N/A 281 - 190 psig (19.4 - 13.1 barg)

Low N/A 22 - 34 psig (1.5 - 2.3 barg)

Air-Cooled Condensers

Air Flow Across Condenser (cfm) (air-cooled models) 60 Hz 300 450 710 1070 2470 1680 2170

50 Hz 250 370 590 890 2060 1400 1810

Condenser Fan Switch Setting (in-out) Fan 1 110 - 70 psig (7.6 - 4.8 barg) 113 - 78 psig (7.8 - 5.4 barg)

Fan 2 N/A 183 - 124 psig (12.6 - 8.6 barg)

Water-Cooled Condensers

Water Regulating Valve Setting N/A 135 psig (9.3 barg)

Required Available Water Pressure Differential N/A 40 psig (2.8 barg) - minimum

Flow Required with 85°F Cooling Water (gallons per minute) 60 Hz N/A 1.3 2.1 2.5 3.0 3.6

50 Hz N/A 1.2 2.0 2.3 2.8 3.3

Electrical Data

Nominal Voltage 115/1/60 208-230/3/60

Min. - Max. Voltage 104 - 127 187 - 253

Input Power @ Rated Flow (watts) 875 1070 1255 1962 2680 2910 4120

Rated Load Amps** 9.5 13.0 7.5 10.4 11.4 13.9 22.1

Locked Rotor Amps** 44.0 70.0 51.0 66.0 75.0 88.0 115.0

Minimum Circuit Ampacity 12.8 18.0 10.5 15.9 20.0 19.7 30.4

Branch Circuit Fuse Size (amps) 20 25 15 20 25 30 45

Resistance (ohms) 4.3 S / 0.6 R 1.06 S / 0.42 R 1.8 1.3 1.1 1.0 0.7

Nominal Voltage 208-230/1/60 460/3/60

Min. - Max. Voltage 187 - 253 414 - 506

Input Power @ Rated Flow (watts) 875 1070 1255 1962 2680 2910 4120

Rated Load Amps** 4.4 6.5 3.6 4.7 5.1 7.1 9.6

Locked Rotor Amps** 20.8 35.0 25.0 33.0 40.0 44.0 63.0

Minimum Circuit Ampacity 6.0 9.1 5.2 7.5 9.6 10.4 15.2

Branch Circuit Fuse Size (amps) 15 15 15 15 15 15 20

Resistance (ohms) Main/Start 7.55 S / 2.52 R 3.95 S / 1.47 R 7.4 5.0 4.1 4.0 2.7

Nominal Voltage 240/1/50 575/3/60

Min. - Max. Voltage 216 - 264 518 - 633

Input Power @ Rated Flow (watts) 612 749 1255 1962 2680 2910 4120

Rated Load Amps** 4.5 5.0 3.6 4.7 5.1 7.1 9.6

Locked Rotor Amps** 21.0 30.0 25.0 33.0 40.0 44.0 63.0

Minimum Circuit Ampacity 6.2 7.3 4.2 6.0 7.7 8.3 12.2

Branch Circuit Fuse Size (amps) 15 15 15 15 15 15 20

Resistance (ohms) 12.7 S / 2.7 R 4.38 S / 1.92 R 7.4 5.0 4.1 4.0 2.7

Nominal Voltage N/A 380-420/3/50

Min. - Max. Voltage N/A 342 - 462

Input Power @ Rated Flow (watts) N/A 1002 1613 1992 2040 2860

Rated Load Amps** N/A 3.6 4.7 5.1 7.1 9.6

Locked Rotor Amps** N/A 25.0 33.0 40.0 44.0 63.0

Minimum Circuit Ampacity N/A 5.2 7.5 8.1 10.4 15.2

Branch Circuit Fuse Size (amps) N/A 15 15 15 15 20

Resistance (ohms) N/A 7.4 5.0 4.1 4.0 2.7

* For 60 Hz, 35°F Evaporator, 100°F Ambient; for 50Hz, 35°F Evaporator, 77°F Ambient

** Compressor Only

This manual suits for next models

7

Table of contents

Other SPX Dehumidifier manuals

SPX

SPX Hankison HPRplus Series User manual

SPX

SPX HCD Series User manual

SPX

SPX Pneumatic Products IBP500 User manual

SPX

SPX HPD Series User manual

SPX

SPX HANKISON HIT Series User manual

SPX

SPX Hankison HPRP Series User manual

SPX

SPX RDH-HP Series User manual

SPX

SPX HANKISON HES Series User manual

SPX

SPX DELAIR QD 90 User manual

Popular Dehumidifier manuals by other brands

Seaira Global

Seaira Global WatchDog 900c Installation and operation manual

LG

LG D451WH owner's manual

ICP

ICP iDRY Instructions for installation and operation

Trotec

Trotec TTK 24 E operating manual

Olimpia splendid

Olimpia splendid SeccoReale Instructions for installation, use and maintenance

omi

omi ED HP40 Instruction and maintenance manual