R290 (Propane) is refrigerant grade propane with high purity and low Global Warming Potential (GWP).

Propane is highly flammable. Please observe caution and follow the safety maintenance requirement when servicing

equipment with R290.

Before the maintenance of R290 refrigeration products, safety inspection must be carried out to ensure that the risk of

ignition is minimized.

The maintenance area must be ventilated.

Fire extinguishing equipment (dry powder or carbon dioxide fire extinguisher)

shall be provided in the maintenance site

There should be enough space in the maintenance site. Open fire, electric spark and ≥470 ℃ heat source are

prohibited within 2m.

The key to maintaining your cabinets

SERVICING GUIDELINES

R290 REFRIGERANT

An electrical wiring diagram can be located under the hood of electrical box

LED driver and electrics can be located in the hood or electrical box

To access fans for service or repair:

Remove deck tray in cabinets and lift out

Remove stainless cover with screw drivers

This will allow access to fans and coil

Operation ambinet temperature ( Climate 4 ): 43 °C

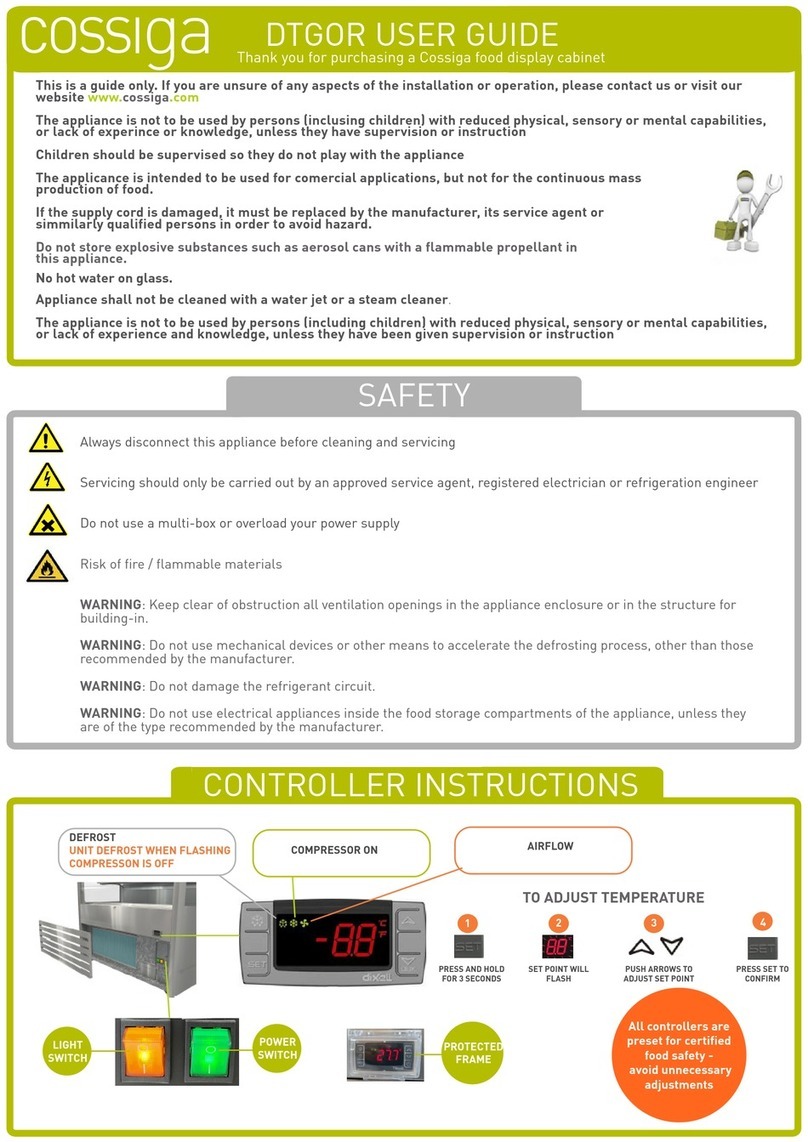

ALWAYS DISCONNECT CABINET BEFORE SERVICING

Electrical diagrams

Exploded spare parts

Refrigerated parameters

Can be found on our website:

www.cossiga.com

Disconnect the power supply

to appliance.

Connect the compressor equipped

with the

venting hose to the piercing valves.

Discharge the R290 refrigerant into

a safe place or a refrigerant

recovery bottle.

Once the charge is removed, add

high-purity nitrogen through the

system for 10 seconds.

Purge nitrogen through the system

at 70 to 140 hPa, vacuum until

unit holds 40pa.

Vacuumize it with a vacuum pump for

15-20min before welding the

replacement parts of R290

refrigeration