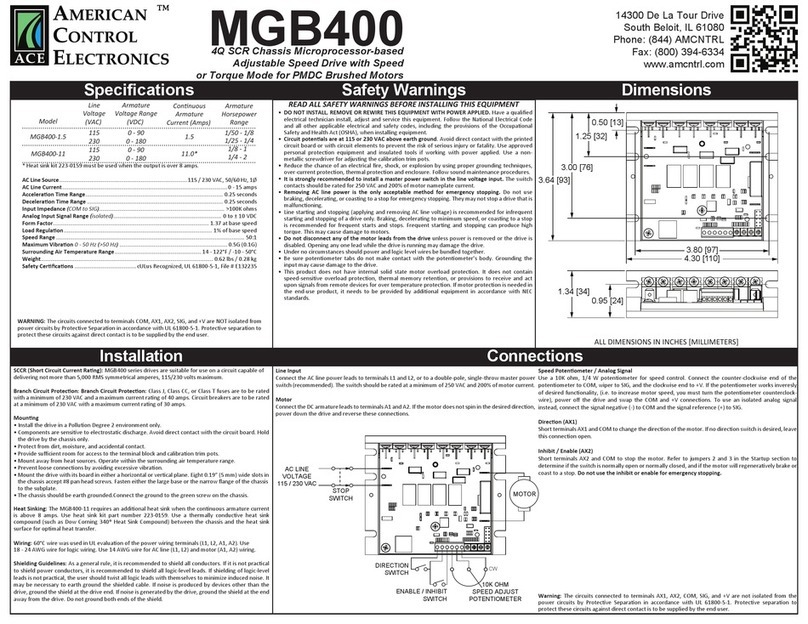

1. Safety Instructions

1

1. Safety Instructions

1-1. General Safety Precautions

Warning! Before using the Inverter, read the safety instructions.

Do not expose the inverter to rain, snow, spray or dust. To reduce

the risk of fire hazard, do not cover or obstruct the ventilation

openings and do not install the inverter in a zero-clearance

compartment.

To avoid the risk of fire and electric shock, make sure that the

existing wiring is in good electrical condition, and the wire size is not

undersized.

This equipment contains components which can produce arcs or

sparks. To prevent fire or explosion do not install in compartments

containing batteries or flammable materials or in locations which

require ignition protected equipment. This includes any space

containing gasoline-powered machinery, fuel tanks, or joints, fittings,

or other connection between components of the fuel system.

Depending on the user scenario, the AC output of the inverter may

require user installed breaker or fuse. In AC output hardwire

application, AC socket will not be provided. The inverter incorporates

standard AC short circuit protection.

The following precautions should be taken when working on the

inverter:

Step 1 Remove watches, rings, or other metal objects

Step 2 Use tools with insulated handles

Step 3 Wear rubber gloves and boots