www.hartmann-electronic.com Rev. 1.2 3

Contents

1. Safety.....................................................................................................................................................................5

Intended Application..............................................................................................................................................5

Safety Symbols .....................................................................................................................................................5

General Safety Precautions ..................................................................................................................................5

Safety Instructions.................................................................................................................................................6

Protection Against Electromagnetic Interference (EMI) .....................................................................................6

Electrostatic Discharge Precautions...................................................................................................................6

Installation ..........................................................................................................................................................6

Location..............................................................................................................................................................6

Voltage Hazards.................................................................................................................................................6

System Overheating...........................................................................................................................................6

Mounting Considerations....................................................................................................................................6

Electrical Hazards...............................................................................................................................................7

Board Installation................................................................................................................................................7

2. Product Description ...............................................................................................................................................8

Related Documentation.........................................................................................................................................8

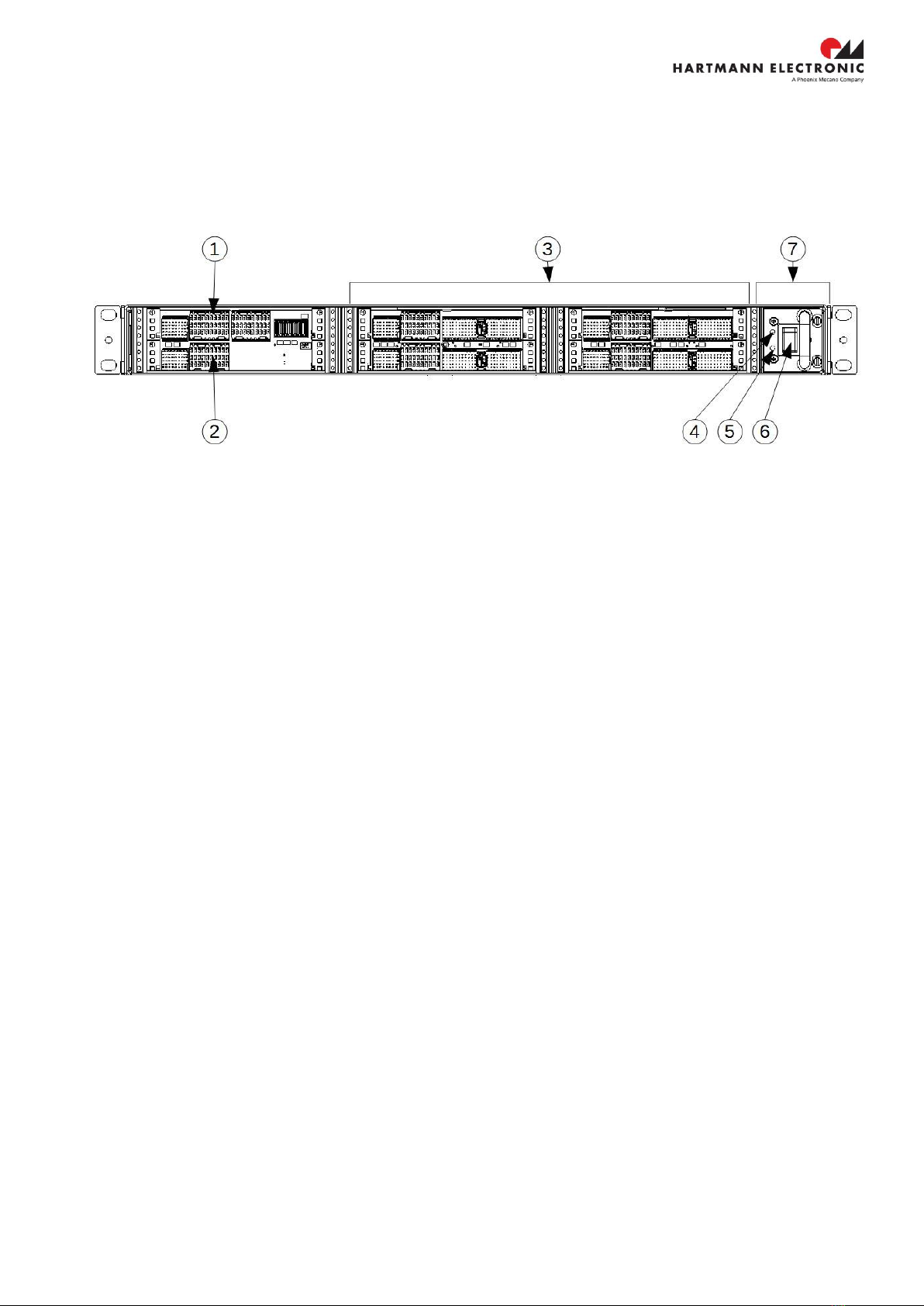

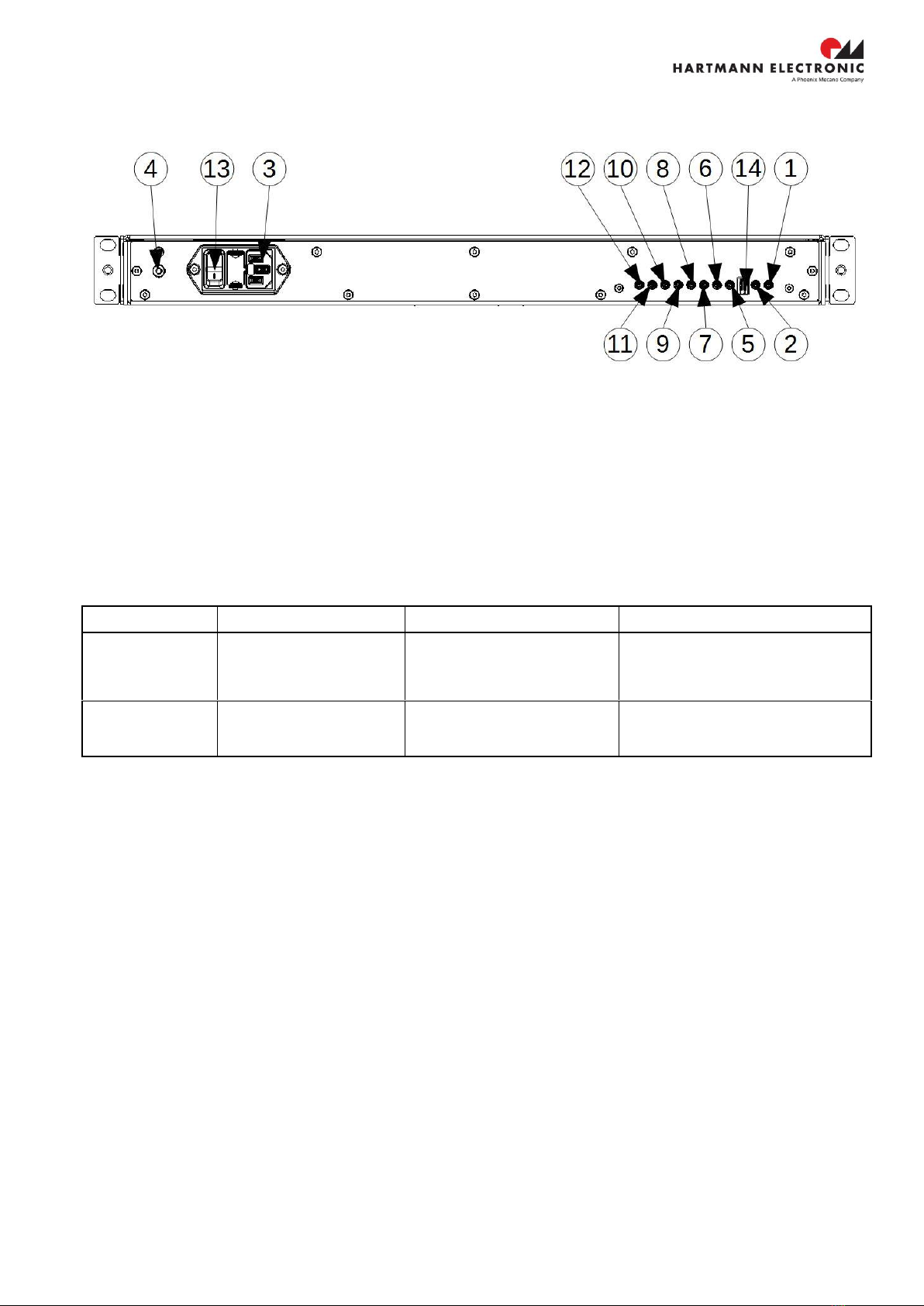

Chassis Description...............................................................................................................................................9

Fan Control..........................................................................................................................................................10

System Controller Slot.........................................................................................................................................12

PXIe Peripheral Slot............................................................................................................................................12

Hybrid Peripheral Slots........................................................................................................................................12

PCI Express Backplane Diagram........................................................................................................................13

PXI Local Bus......................................................................................................................................................13

PXI Trigger Bus...................................................................................................................................................14

System Reference Clock.....................................................................................................................................14

Front Panel LEDs................................................................................................................................................16

Interoperability with CompactPCI........................................................................................................................16

3. Installation............................................................................................................................................................17

Connecting Chassis Grounding ..........................................................................................................................17

Inspecting the Chassis Components...................................................................................................................17

Protection Against Electromagnetic Interference................................................................................................17

Installing Hardware..............................................................................................................................................18

Installing Software...............................................................................................................................................19

4. Maintaining the Chassis.......................................................................................................................................20

Replacing the Fan Tray.......................................................................................................................................20

5. Service.................................................................................................................................................................21

Technical support and Return for Service Assistance ........................................................................................21

Declaration of Conformity....................................................................................................................................21

6. Specification ........................................................................................................................................................22

Electrical..............................................................................................................................................................22

AC Input............................................................................................................................................................22

DC Output.........................................................................................................................................................22

Power available for Backplane.........................................................................................................................22

System Synchronization Clocks.......................................................................................................................23

Operating Environment ....................................................................................................................................23

Cooling Capacity ..............................................................................................................................................24

Electromagnetic Compatibility..........................................................................................................................26

Mechanical .......................................................................................................................................................27

Recessed Mounting..........................................................................................................................................29

Cooling ................................................................................................................................................................30

Airflow...............................................................................................................................................................30

Chassis Material..................................................................................................................................................30

Humidity...............................................................................................................................................................30

Operational Shock...............................................................................................................................................30

Random Vibration................................................................................................................................................30

Safety ..................................................................................................................................................................30

7. Pin Assignment....................................................................................................................................................31

System Controller Slot (4 Link Configuration).....................................................................................................32

PXI Express Hybrid Peripheral Slot ....................................................................................................................33