3

Table of Contents

INTRODUCTION ............................................................................................................................... 5

PREFACE....................................................................................................................................... 5

SPECIFICATIONS........................................................................................................................... 5

ELECTRICAL SPECIFICATIONS........................................................................................................... 6

SAFETY PROCEDURES ...................................................................................................................... 6

BEFORE USE:................................................................................................................................ 6

DURING USE: ............................................................................................................................... 6

AFTER USE: .................................................................................................................................. 6

CARE AND MAINTENANCE............................................................................................................... 7

BEARINGS/BUSHINGS:................................................................................................................. 7

SENSOR EYE: ................................................................................................................................ 7

KEEP THE ROLLERS CLEAN: .......................................................................................................... 7

IMPORTANT NOTES BEFORE OPERATING THE KF-200 .................................................................... 7

DOUBLE FEEDING: ....................................................................................................................... 7

KNOB SETTINGS:.......................................................................................................................... 7

START DELAY: .............................................................................................................................. 7

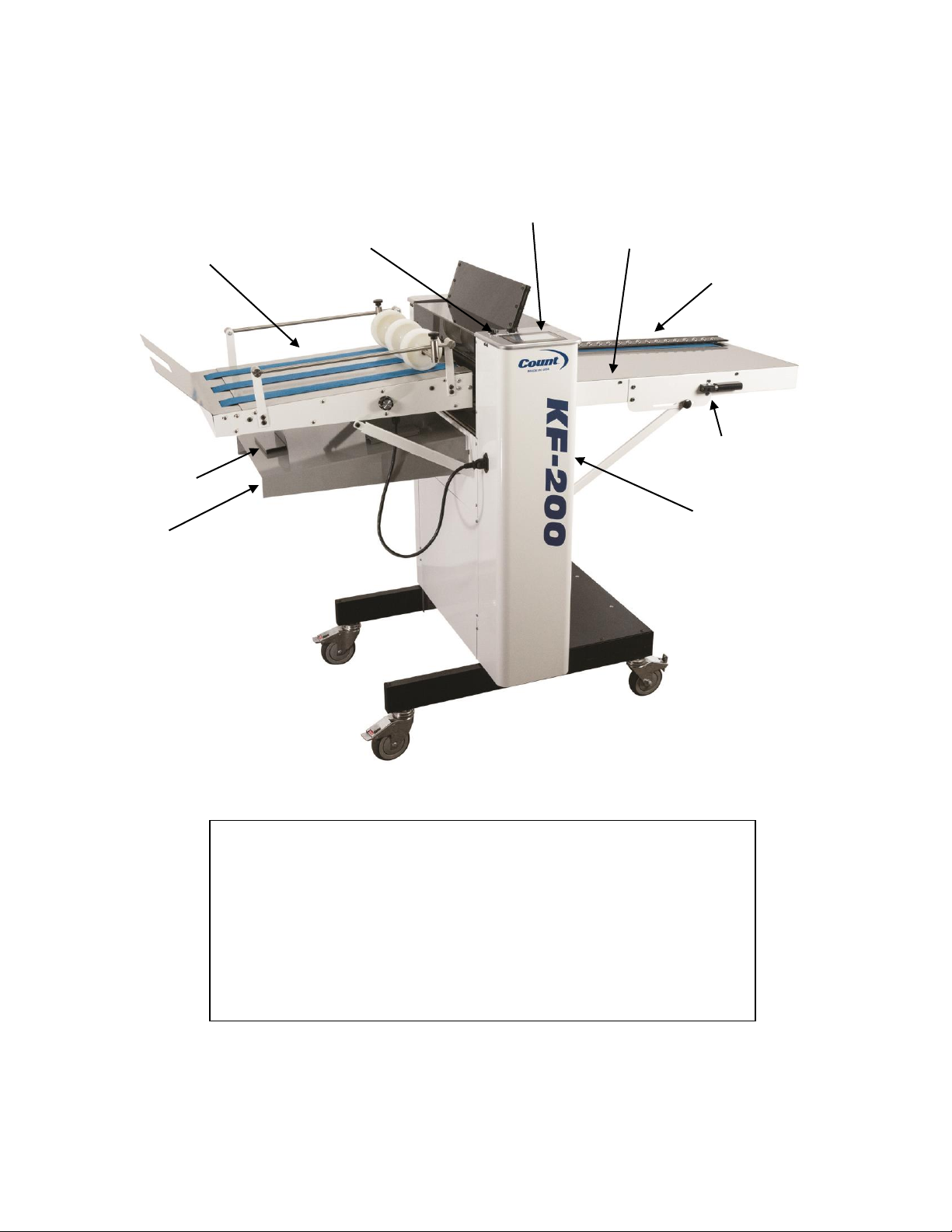

COMPONENT IDENTIFICATION........................................................................................................ 8

SETTING UP YOUR KF-200 ............................................................................................................... 9

DELIVERY TRAY INSTALLATION .................................................................................................... 9

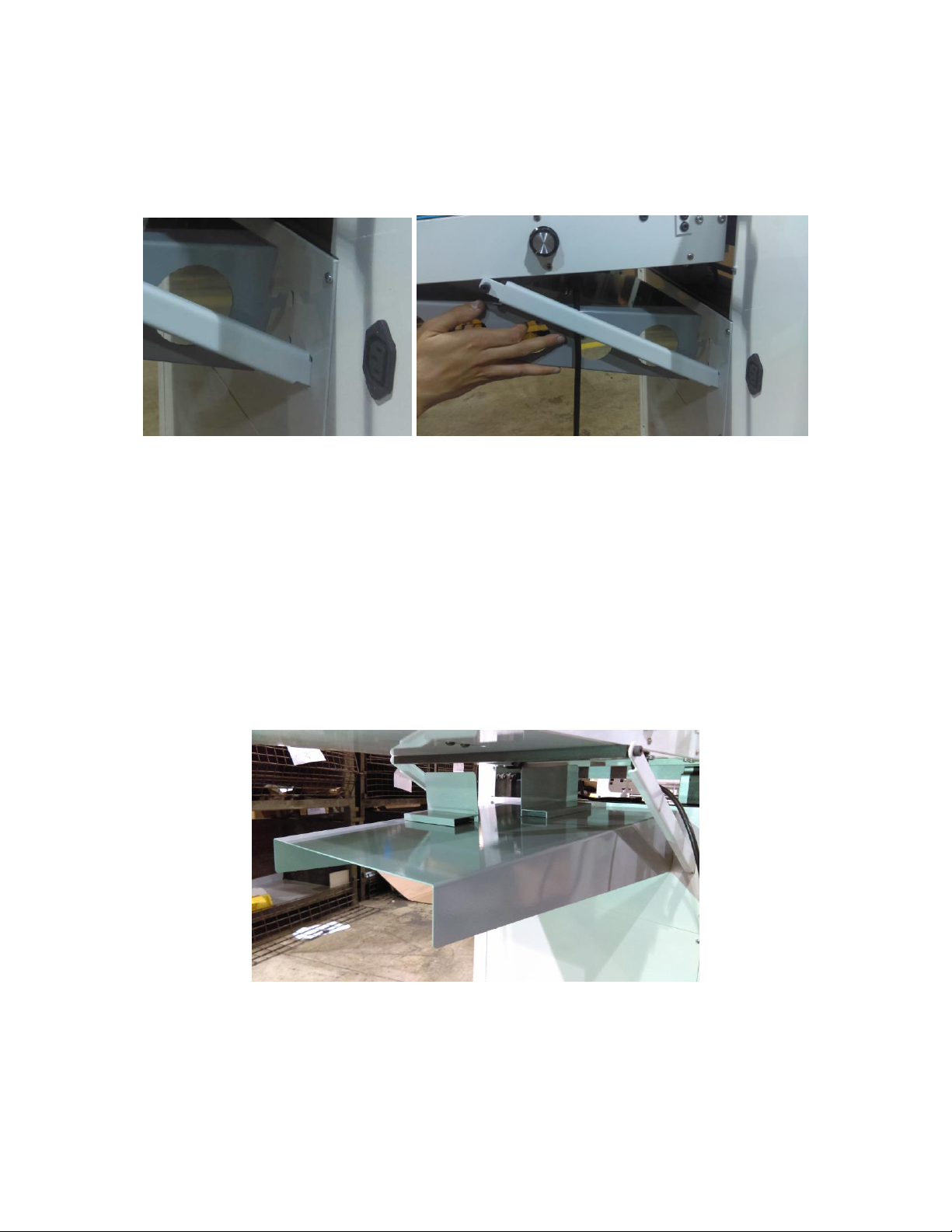

BI-PASS TRAY INSTALLATION....................................................................................................... 9

PAPER STOP ASSEMBLIES .......................................................................................................... 10

REGISTER GUIDE INSTALLATION................................................................................................ 11

Connecting KF-200 to ACCUCREASER / FC114A ............................................................................ 12

CONNECTING TO OTHER EQUIPMENT ...................................................................................... 12

MAIN POWER ............................................................................................................................ 13

TOUCH SCREEN CONTROLLER ....................................................................................................... 14

TOUCH SCREEN OPERATION...................................................................................................... 14

COUNT LOGO AND SERVICE ACCESS ......................................................................................... 14

AUTO SETUP SCREEN................................................................................................................. 15

PAPER THICKNESS...................................................................................................................... 15

KNOB SETTINGS / GAP ADJUSTMENT........................................................................................ 16