2

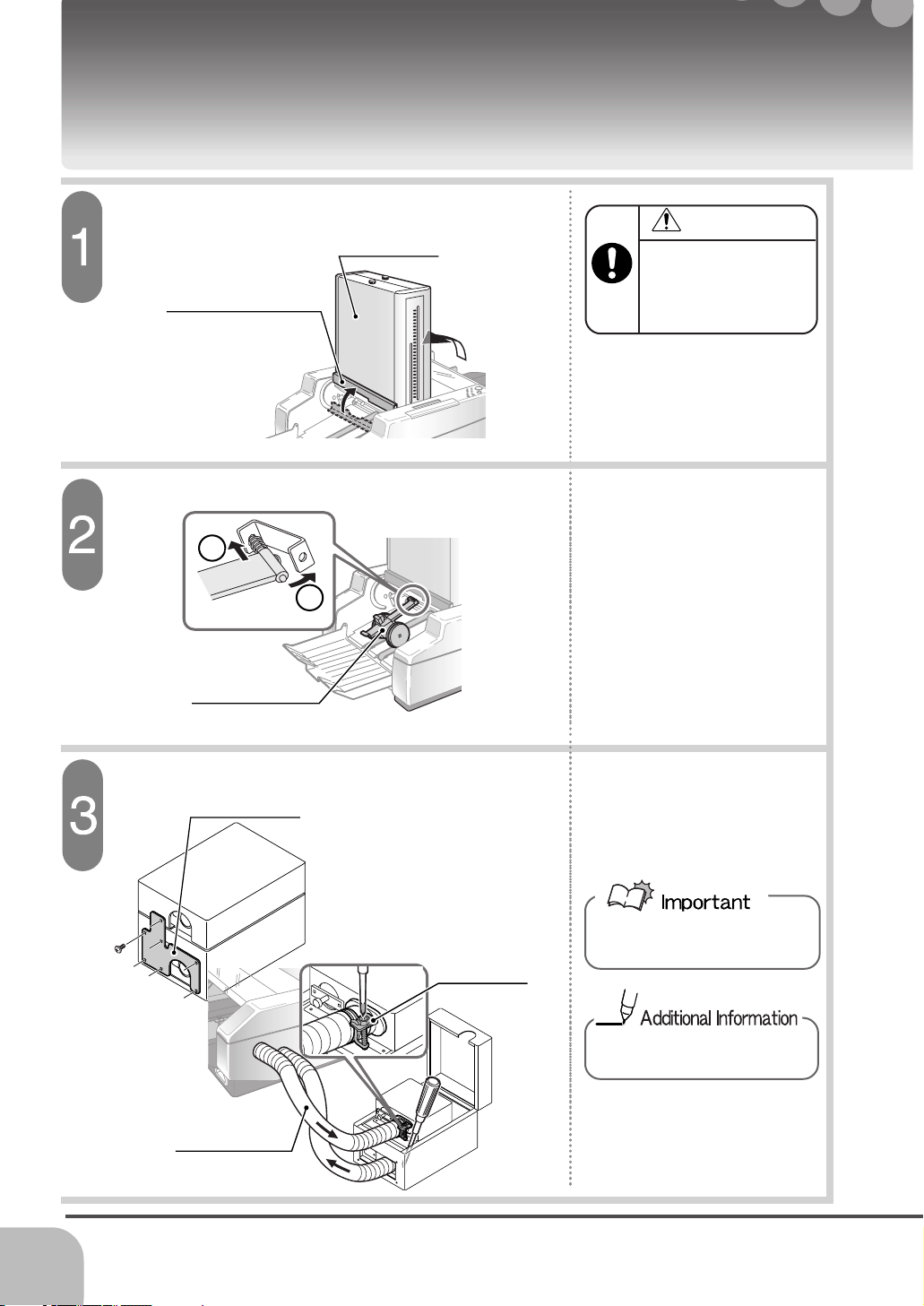

Folding Procedures

1

2

3

4

5

6

7

1514

ABC

PowerSwitch

Fold Pattern Selecting Button.

Sheets set as the left illustration are folded

as the illustration to the below.

When performing the short folding, set the

sheet oppositely as the illustration to the

lower left part shows.

When performing the opposite direction folding,

pile the sheet up sisde down.

Sheet can be piled mazimum 50 mm.

Tighten the sheet guide locking knobs after fitting the guides.

There are 6 folding patterns shown below.

Sheet Size Selecting Button

Sheet Guide Locking Knob

End Stopper

Delivery Roller

Test Button

Start/Stop Button

Sheet Guide

Short Fold

Single Fold

Letter Fold

Parallel Fold

Accordion Fold

Short Fold

Gate Fold

Single Fold

Letter Fold

Parallel Fold

Accordion Fold

Short Fold

Gate Fold

ABC

ABC

ABC

ABC

ABC

Check the folded sheet. If there is a

folding skew, refer to [Troubleshooting]

and perform the adjustment.

¥When folding the specific number of sheets,

refer to [Set the Number of Fold (Pre-set Function)].

¥To quit folding, press the start/stop button again.

Refer to page 22.

Refer to page 16.

ABC

ABC

Start / Stop

Test Feed

Sheet Size

Folding Pattern

81/2"X 11"

81/2"X 14"

51/2"X 81/2"

11"X 17"

Start / Stop

Test Feed

Sheet Size

Folding Pattern

8

1/2

"

X

11"

8

1/2

"

X

14"

5

1/2

"

X

8

1/2

"

11"

X

17"

Start / Stop

Test Feed

Sheet Size

Folding Pattern

8

1/2

"

X

11"

8

1/2

"

X

14"

5

1/2

"

X

8

1/2

"

11"

X

17"

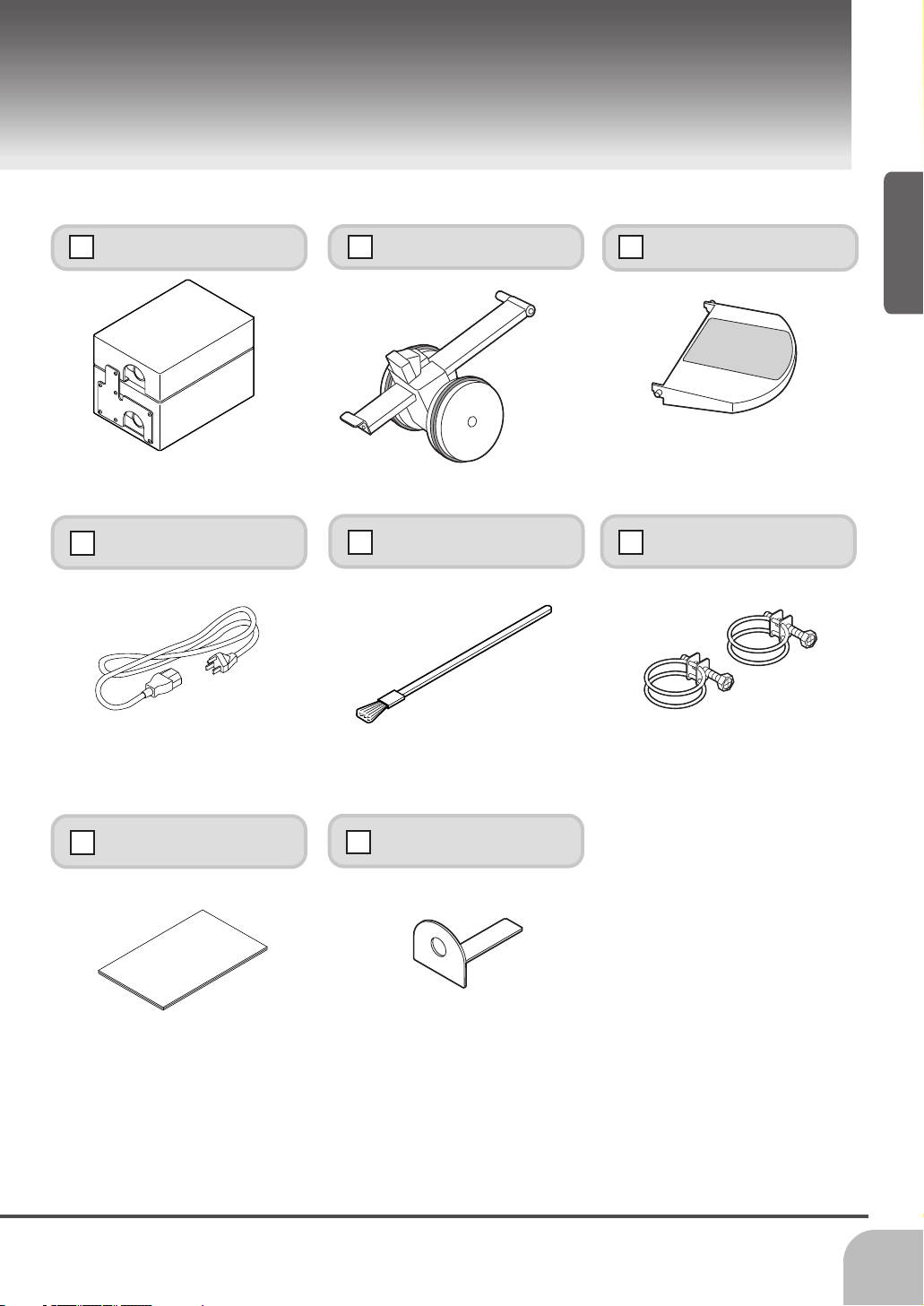

Folding Standard Size Sheet Folding Standard Size Sheet

Let’s fold the standard size (11"x17", 9"x11", 8.5"x11", 5,5"x8.5") sheet.

Turn on the power switch. Set the end stopper.

Set the delivery Roller.

Press the test button.

Press the start/stop button and start folding.

Select the fold pattern and sheet size.

Loosen the sheet guide locking knobs

and place the sheets on the center.

Then fit the sheet guides to the sheet.

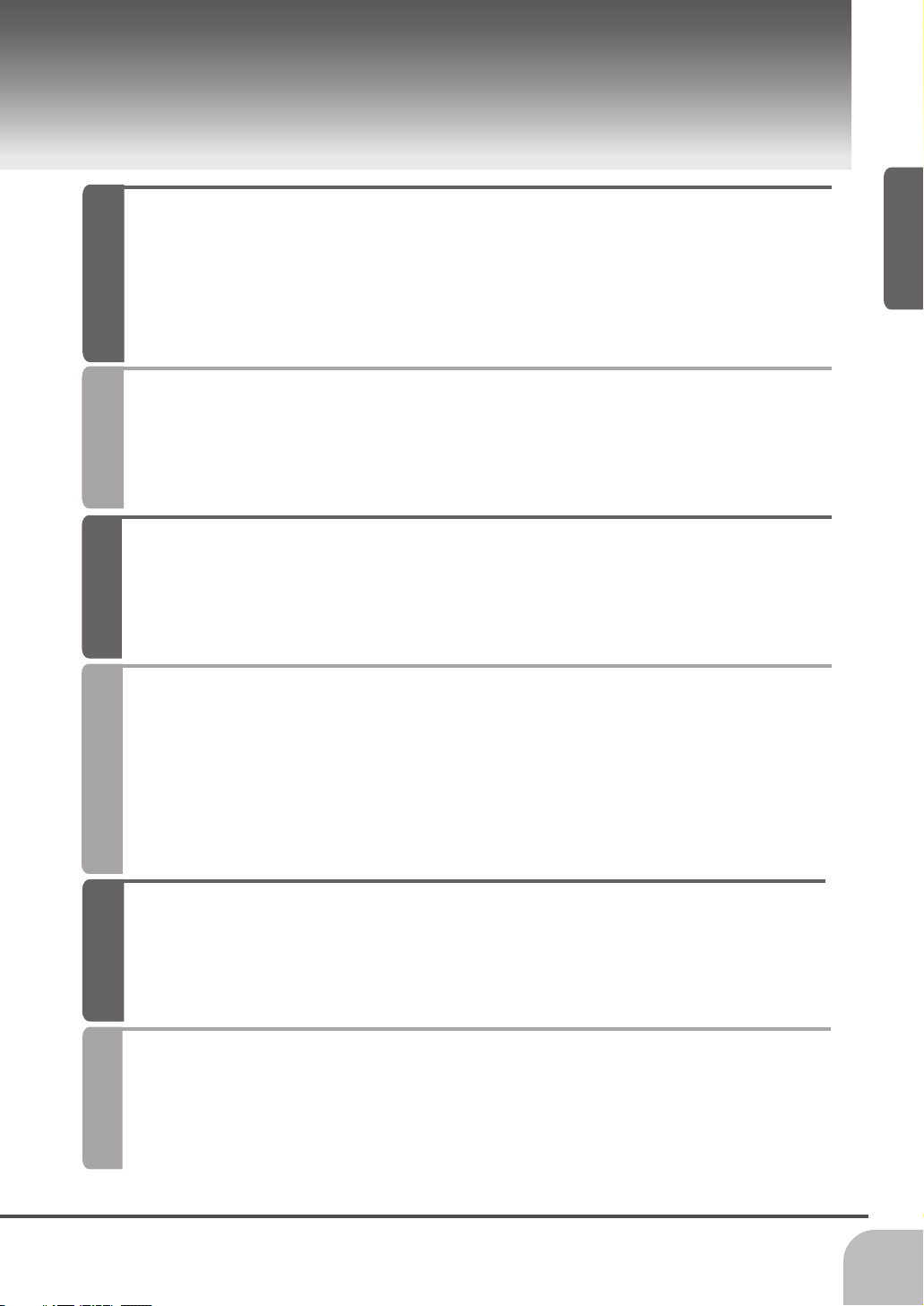

View of This Operation Manual

This mark indicates the title or

page to refer.

Indicates the trick of the operation.

This number indicates the

operating order.

Chapter Title

Topic Title

Explanation

Indicates the summary for

operation described in

this page.

This section explains how to read this operation manual, and how to search the necessary topic.

Indicates the items that you have to be careful during operation.

Indicates the useful informations.