Country Clipper CBS2 User manual

OPERATOR’S MANUAL

ASSEMBLY OPERATION MAINTENANCE

PART# 629GZ-001A

MANUAL#: Q0469 v5.0 - 6/12/2018

PROFESSIONAL BAGGING SYSTEM

Designed To Fit Charger & Challenger Series Mowers

MODEL# CBS2 (49131501)

2

PROFESSIONAL BAGGING SYSTEM

TABLE OF CONTENTS

Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Safety Alert Symbols- - - - - - - - - - - - - - - - - - - - - - 3

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

1-2 Description - - - - - - - - - - - - - - - - - - - - - - - - - 5

II INSTALLATION FOR USE - - - - - - - - - - - - - - - - - - - - - 5

2-1 Preparation Of Mower - - - - - - - - - - - - - - - - - - 5

SECTION PAGE

1-1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - 5

2-2 Right Frame Mount Plate and

I INTRODUCTION AND DESCRIPTION - - - - - - - - - - - - 5

2-9 Blower Cone Installation - - - - - - - - - - - - - - - - - 10

2-11 Upper Frame Assembly Installation - - - - - - - - - 12

2-4 PTO Mount Plate Assembly Installation

2-3 Rear Mount Support Bracket Installation - - - - - - 7

2-8 Cam Assembly Adjustment - - - - - - - - - - - - - - - 10

2-10 Lower Mount Tube Installation - - - - - - - - - - - - 11

2-6 PTO Handle Installation - - - - - - - - - - - - - - - - - 9

Rear Mount Plate Installation - - - - - - - - - - - - - - 6

2-12 Top Assembly To Upper Frame

Assembly Installation - - - - - - - - - - - - - - - - - - 12

2-5 PTO Assembly Installation - - - - - - - - - - - - - - - 9

2-7 Belt Installation/Removal and Adjustment- - - - - - 9

and Exhaust Diverter Installation - - - - - - - - - - - 8

2-13 Hinge Kit Assembly Installation- - - - - - - - - - - - 13

Exploded Part Views and Assemblies - - - - - - - - - 19-24

2-22 Installation and Removal Of Collection Bags - - - 18

3-2 Operation & Tips On Mowing - - - - - - - - - - - - - - 25

3-4 Unloading The Collection System - - - - - - - - - - - 25

2-20 Impeller Blade Removal/Installation- - - - - - - - - 16

SECTION PAGE

2-15 Boot To Mower Deck Installation - - - - - - - - - - - 14

2-17 Upper Hose Installation - - - - - - - - - - - - - - - - 15

2-18 Lower Hose To Blower Cone Installation- - - - - - 15

2-14 Boot Plate Installation- - - - - - - - - - - - - - - - - - 14

2-16 Length Of Hose Adjustment - - - - - - - - - - - - - - 15

2-19 Lower Hose To Boot Installation - - - - - - - - - - - 15

2-21 Weight Kit Installation- - - - - - - - - - - - - - - - - - -17

III OPERATING INSTRUCTIONS - - - - - - - - - - - - - - - - - - 25

3-1 General Safety - - - - - - - - - - - - - - - - - - - - - - - 25

3-3 Disengagement Of The PTO Assy. - - - - - - - - - - 25

Safety Decals - - - - - - - - - - - - - - - - - - - - - - - - - - 27

4-2 Lubrication- - - - - - - - - - - - - - - - - - - - - - - - - - 26

V PARTS AND SERVICE - - - - - - - - - - - - - - - - - - - - - - 26

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

IV MAINTENANCE - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

4-1 Maintenance Checklist - - - - - - - - - - - - - - - - - - 25

5-1 Parts And Service Information - - - - - - - - - - - - - 26

Torque Specifications - - - - - - - - - - - - - - - - - - - - - 28

SAFETY

you.

6. Do not attempt to operate your machine when not in the driver’s seat.

7. Always shut off blades and engine when emptying the container.

8. Stop machine, shut off deck attachment, set parking brake, shut off engine and remove ignition key before

removing clogs, removing or replacing hose, boot, blower cone, or performing any maintenance.

2. Know the controls and how to stop them quickly. READ THE OPERATOR’S MANUAL!

4. Be especially watchful of children and pets entering into the area while operating.

3. Do not allow children to operate the machine. Do not allow adults to operate it without proper instruction.

1. Read the operator’s manual carefully and familiarize yourself with the proper use of your attachment. Do not allow

anyone who is not acquainted with the Safety Instructions to use your attachment.

5. Keep your eyes and mind on your machine while mowing or operating your attachment. Don’t let others distract

9. Mow across the face of slopes (not more than 10 degrees); never up and down the face.

10. It is recommended that the container be emptied when half full while operating on slopes. Start mowing on slopes

12. Wear hearing protection.

13. Wear eye protection to prevent debris from getting into your eyes.

foreign object.

11. Inspect your lawn and remove any foreign objects before mowing. Never deliberately run the mower across any

when the container is empty.

2017 (v1.0)

3

WARNING! To avoid serious injury, perform maintenance on the vacuum collector; ONLY AFTER

STOPPING THE MOWER’S ENGINE AND WAITING FOR ALL MOVING PARTS TO COME TO A

COMPLETE STOP. Set the parking brake. Always remove the ignition key before beginning maintenance.

ALERT! YOUR SAFETY IS INVOLVED!”

Should be followed by the operator to avoid accidents. When

WARNING! For your own personal safety, ALWAYS mow ACROSS the face of slopes and

NEVER UP and DOWN the face. NEVER attempt to mow excessively steep slopes, and use

caution when turning on any slope.

SAFETY

WARNING! NEVER operate the mower unless the discharge guard and either the deflector assembly or

the vacuum collector adapter are fastened securely in place.

WARNING! Do not work around the mower deck boot or the blower area until you are certain that the mower

blades and the blower impeller have stopped rotating.

Safety Alert Symbol

This Safety Alert Symbol means: “ATTENTION! BECOME

This symbol is used to call attention to safety precautions that

you see this symbol, carefully read the message that follows

could result in death or serious bodily injury.

The signal words DANGER, WARNING, and CAUTION are used on the equipment safety signs. These words

are intended to alert the viewer to the existence and the degree of hazard seriousness.

and heed its advice. Failure to comply with safety precautions

Safety Signs

DANGER

!

CAUTION

This signal word indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

It may also be used to alert against unsafe practices.

It may also be used to alert against unsafe practices.

This signal word indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury.

White letters on RED

Black letters on ORANGE

Black letters on YELLOW

WARNING

!

!

!

2017 (v1.0)

42017 (v1.0)

PECO LIMITED WARRANTY FOR NEW PRODUCTS

E. ACCIDENTS AND NORMAL MAINTENANCE

Engines and batteries attached to PECO products are covered under a separate warranty by the respective

manufacturer.

C. ITEMS NOT COVERED BY PECO WARRANTY

2. PARTS REPLACED DURING WARRANTY: Any new PECO part which is furnished in performance of

this warranty and is defective in material or workmanship as delivered to the purchaser will be repaired or

replaced, before the expiration of the original warranty period, whichever is later.

A. WHAT IS UNDER WARRANTY?

The warranty covers only defective material and workmanship. It does not cover depreciation or damage

caused by normal wear, accident, improper use or abuse of products. The cost of normal maintenance and

normal replacement of service items such as belts, cutting blades, hoses, etc., which are not defective shall be

paid for by the purchaser.

1. NO SERVICE CENTER WARRANTY

The only remedies the purchaser has in connection with the breach or performance of any warranty on New

PECO, Inc. consumer products are set forth above. In no event will PECO be liable for special incidental or

consequential damages.

H. REMEDIED EXCLUSIVE

The selling Service Center makes no warranty on his own on any item warranted by New PECO, Inc. unless he

delivers to purchaser a separate written warranty certificate specifically warranting the item. The dealer has no

authority to make any representation or promise on behalf of PECO or to modify the terms of this warranty in

any way.

from the date of delivery of the product to the original purchaser when used for in commercial applications.

Products designated as 'Residential' are warrantied for 90 days from the date of delivery of the product to the

original purchaser when in commercial applications.

Call PECO for Return Authorization. Damaged or broken parts other than engines or batteries, must be

returned to New PECO, Inc. at 10 Walden Drive, Arden, NC 28704 before any warranty adjustment can be

authorized. At the time of requesting warranty adjustment, the purchaser must present evidence of the date of

delivery of the product. The purchaser shall pay any charge for the product to and from Arden, NC.

D. UNAPPROVED ALTERATION OR MODIFICATION

B. SECURING WARRANTY ADJUSTMENTS

Neither New PECO, Inc. nor any company affiliated with it makes any warranties, representations or promises

as to the quality of performance of its products other than those set forth herein. Except as described above,

New PECO, Inc. makes no other warranties AND SPECIFICALLY DISCLAIMS ANY AND ALL IMPLIED

WARRANTIES OF FITNESS AND MERCHANTABILITY.

All obligations of New PECO, Inc. under this warranty shall be terminated if products are altered or modified in

ways not approved by New PECO, Inc.

3. COMMERCIAL USE: Products put to personal use around a single household or residence is considered

'Residential'; Products put to any business use (agricultural, commercial, or industrial) or used at multiple

locations is considered 'Commercial.' Products designated as 'Commercial' are warrantied for 12 months

PECO extends the following warranties to the original purchaser of each new PECO consumer product subject

to the following limitations.

F. NO REPRESENTATIONS ADDITIONAL WARRANTIES, DISCLAIMER

1. PRODUCT WARRANTY: Any part of any consumer product, which is defective in material or

workmanship as delivered to the purchaser will be repaired or replaced, as PECO elects, without charge for

parts or labor, if the defect appears within 12 months from the date of delivery of the product to the original

purchaser. ALL DEFECTIVE PARTS MUST BE RETURNED TO PECO FOR INSPECTION TO DETERMINE

VALIDITY OF WARRANTY CLAIMS. Freight and mailing will be borne by the customer.

G. PRODUCTS USED FOR RENTAL OR LEASE PURPOSES ARE WARRANTIED FOR 45 DAYS

FROM DATE OF ORIGINAL SALE ONLY

5

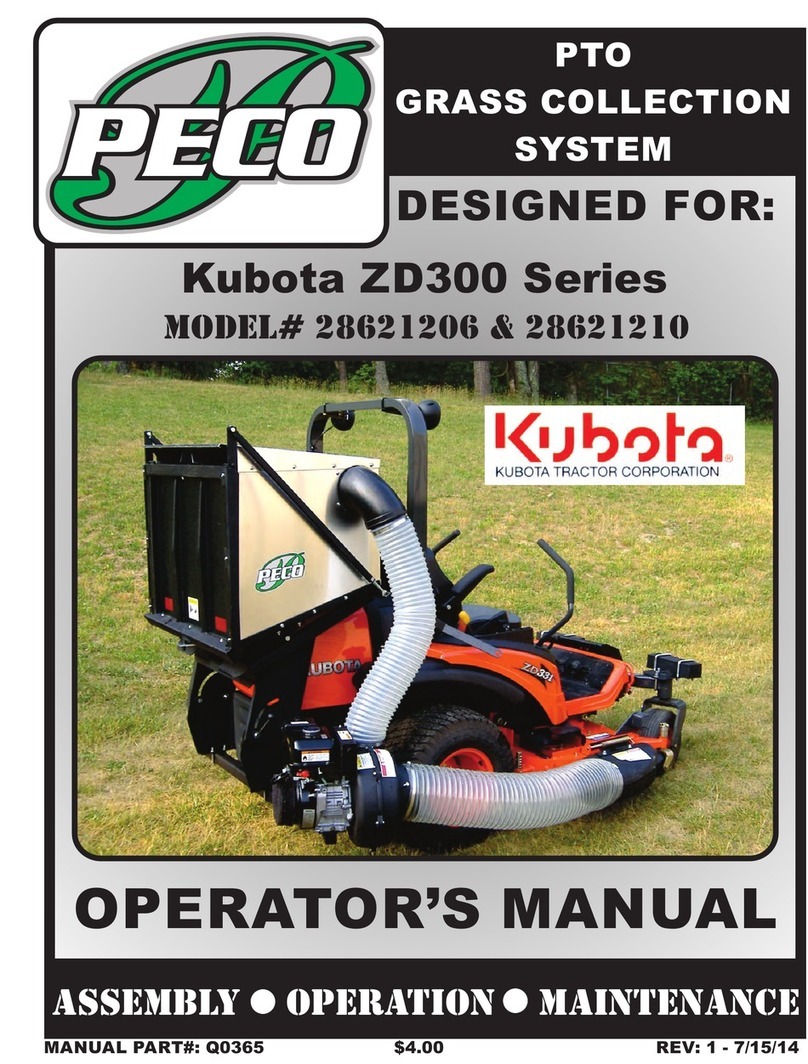

Your grass collection system has been designed to give

you a low maintenance, simple, and effective way to

collect the grass clippings from your mower. This manual

is provided to give you the necessary instructions to

properly mount and operate the collection system on

your mower. Please read this manual thoroughly.

Understand what each control is for and how to use it.

Observe all safety decal precautions on the machine and

noted throughout the manual.

NOTE: all references made to right, left, front, rear, top

or bottom are as viewed from the normal operator’s

position on the mower.

1-2 Description

1-1 Introduction

The grass collection system is designed for turf

maintenance where there is a need to collect the grass

clippings as the mower cuts the turf. It is also used for

picking up leaves and twigs in pre-season and post-

season clean-up.The blower, mounted on the right side

of the unit, uses a belt and gearbox system from the

engine PTO shaft. Drive train protection comes through

belt slippage. The blower draws grass clippings from the

discharge area of the cutter deck back to the (3) - 4.0

cubic foot collection bags P#(G0003) at the rear portion

of the mower frame. The operator can engage the blower

with a push of the over-center linkage on the right side of

the unit. Once the bags are full with clippings, they can

be released to make for easy dumping.

Section II - Installation For Use

Remove deck drive belt from the clutch pulley (refer to

your Country Clipper operator’s manual). From the

underside of the engine, disconnect the wiring harness

attached to the electric clutch. Remove the bolt and

electric clutch from the mower. Next, remove the D-drive

spacer using an arbor press or equivalent. On removal,

adjacent bearing OUTER race must be supported or

bearing damage may occur. Refer to Figure 2-1a.

2-1 Preparation Of Mower

SECTION I - INTRODUCTION AND DESCRIPTION

Once the Engine Pulley Bushing P#(S0191) is installed,

reattach the clutch assembly to the mower and then

review Figure 2-1c. To assemble and fasten the Engine

Pulley, align Pulley hole to the Engine Pulley Bushing

and fasten using (1) Clamp Washer P#(K0278), (1)

7/16” lock washer P#(K0140), and 7/16”-20 x 3-1/2” hex

bolt P#(K0550). Torque the bolt to 55 ft./lbs. The added

pulley will power the collection system and should

resemble Figure 2-1d when installed.

The engine pulley bushing must be installed using an

arbor press or equivalent. Upon Installation, opposite

bearing inner race must be supported or bearing

damage may occur. Refer to Figure 2-1b.

PRESS

Figure 2-1a

PRESS

Figure 2-1b

Engine Pulley Bushing Installation

Electric Clutch

Figure 2-1d

Engine Pulley

Bushing

Hex Bolt

Lock Washer

Pulley

Bushing

Number

Located

Here

Figure 2-1c

Use M0266 (4.25” OD) For Charger Mowers

Use M0309 (4.75” OD) For Challenger Mowers

Clamp Washer

Pulley

Engine Pulley Assembled Into Electric Clutch

6

Kohler Command 27HP

Kohler Command 27HP

Kawasaki FX801V,

FS730V & B&S 30HP

Kawasaki FX801V,

FS730V & B&S 30HP

Kawasaki FX801V,

FS730V & B&S 30HP

Kohler Command 27HP Kawasaki FX801V,

FS730V & B&S 30HP

Kohler Command 27HP

Kawasaki FX801V,

FS730V & B&S 30HP

Kohler Command 27HP

Kohler Command 27HP

Kawasaki FX801V,

FS730V & B&S 30HP

NOTE: The 2013 Charger Series will

require an after-market auxiliary

cooling kit. Contact your Country

Clipper dealer for purchasing

information for this auxiliary cooling

kit (Part Number 629GE-001A).

hole locations specific to your

Use Figure 2-2b for mounting

engine model.

2-2 Right Frame Mount Bracket and

Rear Mount Plate Installation

Remove rear engine guard and hardware. Secure the

right frame bracket P#(B0810) to the rear frame of the

mower using (1) 1/2”-13 x 2” P#(K1234) HHCS, (1)

1/2”-13 x 1” HHCS P#(K1231) and (2) 1/2”-13 nylon

flange locknut P#(K2012). Secure the rear mount plate

to the right frame bracket and rear frame of the mower

using (4) 3/8”-16 x 1” HHCS and P#(K1191) and (4)

3/8”-16 nylon flange locknuts P#(K2038). Refer to

Figure 2-2a.

(4) 3/8”-16 x 1”

Hex Bolts

(4) 3/8”-16 Locknuts

Right Frame

Bracket

(1) 1/2”-13 x 2”

(1) 1/2”-13 Locknut

Figure 2-2a

(1) 1/2”-13 x 1”

(1) 1/2”-13 Locknut

Figure 2-2b

7

Secure the rear mount support bracket P#(B0816) to the

rear mount plate and bumper guard, using the (2)

existing 1/2” -13 hex bolts and nuts and (2) 3/8”-16 x 1”

HHCS P#(K1191) and (2) 3/8”-16 locknuts P#(K2038).

The rear mount support bracket should be installed to

the inside of the bumper guard and rear frame bracket.

Refer to Figure 2-3a and 2-3b.

2-3 Rear Mount Support Bracket

Installation

Figure 2-3a

Rear Mount

Support Bracket

Existing

Hardware

Rear Mount

Plate

Existing

Hardware

Bumper

Guard

Rear Mount Support

Bracket Mounts to

Inside of Rear Mount Plate

and Bumper Guard

Figure 2-3b

(2) 3/8”-16 x 1”

HHCS

(2) 3/8”-16

Locknuts

8

2-4 PTO Mount Plate Assembly

Installation and Exhaust Diverter

Installation

Secure the left PTO mount plate P#(B0813) to the right

frame bracket using (1) 3/8”-16 x 1” HHCS P#(K1191),

(1) 3/8” flat washer P#(K0047) and (1) 3/8”-16 nylon

flange locknut P#(K2038). Secure the bottom section of

the mount plate to the right frame bracket using (1) 1/2”-

13 x 2” HHCS and P#(K1234) and (1) 1/2”-13 nylon

flange locknut P#(K2012). Refer to Figure 2-4a for

reference. Leave the hardware finger tight until the PTO

stop plate has been installed.

For engine models that divert exhaust to the right side,

attach the exhaust diverter P#(J0292) to the muffler as

shown in Figure 2-4b. Fasten the deflector using the

exhaust clamp P#(X1064). Angle the diverter so that the

exhaust does not burn the cloth bags.

Secure the right PTO mount plate P#(B0814) to the

right frame bracket using (1) 3/8”-16 x 1” HHCS

P#(K1191), (1) 3/8” flat washer P#(K0047) and (1) 3/8”-

16 nylon flange locknut P#(K2038). Secure the bottom

section of the mount plate to the right frame bracket

using (1) 1/2”-13 x 1-1/2” HHCS P#(K1233) and 1/2”-13

locknut P#(K2012). Refer to Figure 2-4 for reference.

Leave the hardware finger tight until the PTO stop plate

has been installed. Secure the PTO stop plate

P#(B0733) to the left and right PTO mount plates using

(4) 1/4”-20 x 3/4” HHCS P#(K1222) and (4) 1/4”-20

nylon flange locknuts P#(K2014). Tighten all hardware

at this time. Refer to Figure 2-4a.

Left PTO

Mount Plate

(1) 3/8”-16 x 1” HHCS

(1) 3/8” Flat Washer

(1) 3/8”-16 Locknut

Right PTO

Mount Plate

(4) 1/4”-20 x 3/4” HHCS

(4) 1/4”-20 Locknuts

PTO Stop

Plate

(1) 1/2”-13 x 2” HHCS

(1) 1/2”-13 Locknut

Figure 2-4a

(1) 3/8”-16 x 1” HHCS

(1) 3/8” Flat Washer

(1) 3/8”-16 Locknut

(1) 1/2”-13 x 1-1/2” HHCS

(1) 1/2”-13 Locknut

Figure 2-4b Exhaust Clamp

Attach Diverter

9

To mount the PTO assembly, insert the pivot rod on the

PTO assembly P#(A1623) into the mounting slots

located on the left & right PTO mount plates. Tilt the

PTO assembly upward and insert the PTO mount pin

P#(B0274) through the hole in the top of the right PTO

mount plate assembly. Secure the PTO mount pin using

1/8” x 2-3/8” hair pin clip P#(K0086) as shown in Figure

2-5.

Mount the PTO handle assembly P#(A1142) to the

universal PTO P#(A1623) using (3) 1/4”-20 x 3/4” HHCS

P#(K1222) and (3) 1/4”-20 nyloc nuts P#(K1128).

Before fastening, make sure that there is room for the

handle to engage and disengage without the handle

hitting the mower’s fuel tank. Attach the handle grip

P#(J0522) to the PTO handle assembly. See Figure 2-6

for reference.

2-5 Universal PTO Installation

2-6 PTO Handle Assembly Installation

Remove the belt guard. Loosen the (4) bolts P#(K1191),

(2) on each side, that secure the gear box assembly to

the PTO assembly P#(A1623) (Figure 2-7a and 2-7b).

Loosen the adjustment bolt P#(K0348) until the gear

box assembly is at its far left adjustment (the gear box is

moved toward the mower’s engine pulley). Connect the

kevlar cord belt (A54K P#(M0255) for Charger Mowers)

or (A55K P#(M0248) for Challenger Mowers) from the

engine pulley to the lower gear box pulley (Figure 2-7c).

To tension the drive belt, turn the adjustment bolt

clockwise until there is 1” of deflection, with 10-11 lbs.

of pressure, at the center of the belt between the engine

pulley and the gear box pulley. Once the correct tension

of the belt is achieved, tighten the (4) bolts that secure

the gear box assembly. Replace the belt guard.

2-7 Belt Installation

PTO Mount

Pin

Hair Pin

Clip

Pivot

Rod

Figure 2-5

Figure 2-6

(3) 1/4”-20 x 3/4” HHCS

(3) 1/4”-20 Nyloc Nut

PTO Handle

Assembly

Loosen

Bolts

Loosen

Bolts

Gear Box

Assembly

Belt

Guard

Adjustment

Bolt

Engine

Pulley

Gear Box

Pulley

Figure 2-7a

Figure 2-7b

Figure 2-7c

10

2-8 Cam Assembly Adjustment

The cam assembly P#(A0422), which controls the blower belt tension, comes from the factory pre-adjusted. If the belt

is too tight or becomes too loose, remove the hair pin clip P#(K0130) from the belt tension rod P#(K0326) and pull the

“L” end of the rod out of it’s hole in the cam assembly. The tension rod may then be screwed out to tighten the belt or

screwed in to loosen the belt. Replace the “L” end into the top hole in the cam and replace the hair pin clip. Adjust the

cam stop bolt P#(K1159) to allow the cam to rotate slightly over center when the blower is engaged (Figure 2-8).

Thread (1) 5/16”-18 jam nut P#(K0120) onto each end of (2) 5/16”-18 x 2-1/2” HHCS P#(K0125). Now partially thread

the bolts into each of the two tabs located on the blower housing. Place blower cone so the two tabs line up with the

bolts then tighten completely. Refer to Figure 2-9 for reference.

2-9 Blower Cone Installation

Figure 2-8

Cam

Assembly

Cam Stop

Bolt

Tension

Rod

Figure 2-9

(2) 5/16”-18 x 2-1/2”

All Thread HHCS Blower

Housing Tab

(2) 5/16”

Jam Nut

Blower

Housing

Blower

Cone Tab

11

Secure the lower mount tubes P#(B0752) to the rear

mount bracket using (2) 5/16”-18 x 2-1/4” u-bolts

P#(K1098) and (4) 5/16”-18 nylon flange locknuts

P#(K2516) PER TUBE. The bottom edge of the lower

mount tubes should be flush with the top edge of the

bumper guard before the hardware is tightened. Refer to

Figure 2-10.

2-10 Lower Mount Tube Installation

Figure 2-10

(2) 5/16”-18 U-Bolts

(4) 5/16”-18 Locknuts

PER Tube

Lower Mount

Tubes

12

2-11 Upper Frame Assembly

Installation

NOTE: During this step, it is suggested that two people

install the upper frame to the lower mount tube.

Lift the upper frame assembly P#(A1058) above the

lower mount assembly and lower the top assembly onto

the two vertical tubes. Secure the top assembly to the

lower mount assembly using (2) clevis pins P#(K0133)

and (2) hair pin clips P#(K0088). Refer to Figure 2-11.

2-12 Top Assembly To Upper Frame

Assembly Installation

Position the top assembly P#(A1190) above the upper

frame assembly as shown in Figure 2-11. Fasten the top

assembly to the upper frame assembly using (2) 5/16”-

18 x 2-1/2” HHCS P#(K0125) and (2) 5/16”-18 nylon

flange locknuts P#(K2516). Leave the locknuts slightly

loose, to allow the top assembly to open and close

easily.

Figure 2-11

Top Assembly

Upper Frame

Assembly

(1) 5/16-18 x 2-1/2” HHCS

(1) 5/16”-18 Nylon Flange

Locknut

Hair Pin

Clip

Clevis Pin

13

2-13 Hinge Kit Assembly Installation

Assemble the hinge kit as shown in Figure 2-13, using

(2) 5/16”-18 x 1” HHCS P#(K1154), (3) 5/16”-18 nylon

flange locknuts P#(K2516), (5) 1/4” flat washers

P#(K0037) and (2) swing arm brackets P#(ZT-0004).

Place (1) vinyl cap P#(J0289) on the end of the hex bolts

as shown in Figure 2-13. Leave the nuts loose enough to

allow fluid movement of the top when opening and

closing. When opened, the top should rest on the middle

joint of the hinge allowing it to remain up.

ZT-0004

K2516

K0037

K1154

J0289

Figure 2-11

14

Secure the boot plate P#(B0820) to the aluminum boot

P#(E1902) using (2) 3/8”-16 x 1” carriage bolts

P#(K1182) and (2) 3/8”-16 nylon flange locknuts

P#(K2038). Insert the carriage bolts from the inside of

the boot so the threads are on the top of the boot. This

will prevent grass clippings from collecting on the

threads. Leave the hardware loose until the boot plate

has been attached to the mower deck.

Refer to Figure 2-14a and 2-14b for Challenger Mowers

or 2-14c for Charger Mowers.

2-14 Boot Plate Installation 2-15 Boot To Mower Deck Installation

Remove the hardware from the grass deflector and

insert (1) boot rod P#(B4331) into the grass deflector

mounting holes as shown in Figure 2-14a. Secure the

boot rod using (1) hair pin clip P#(K0099). With the

carriage bolts from Section 2-14 still loose, adjust the

position of the boot so that there is no gap between the

mower deck and the boot. Tighten the hardware at this

time.

Boot Rod

(2) 3/8”-16 x 1”

Carriage Bolts

(2) 3/8”-16

Locknuts

Boot Plate

Aluminum

Boot

Hair Pin

Clip

Figure 2-14a

Figure 2-14c

Charger

Mounting Holes

Figure 2-14b

Challenger

Mounting Holes

15

Installation

2-18 Lower Hose To Blower Cone

Slide a hose clamp P#(J0080) over both ends of

the lower hose. Then proceed to slide the lower hose

onto the blower cone. Tighten the hose clamp. Refer to

Figure 2-19.

Take the unattached end of the lower hose and slide it

clamp to secure the hose to the boot (Figure 2-19). Tip:

Before securing clamp rotate hose counter-clockwise

boot to mower deck.

(away from yourself) approximately 1” to aid in retaining

2-19 Lower Hose To Boot Installation

over the circular end of the boot. Use the lower hose

(Figure 2-19) for details. Make sure both ends of the

assembly inlet. Tighten the hose clamps.

blower assembly, and the deck boot.

adjust for the blower assembly’s movement as well as

hoses until you have tried to fit them on your machine.

allow for enough clamping surface between the inlet,

end of the 6” hose onto the inlet. Make sure there is

Slide a pre-assembled hose clamp P#(J0060) onto both

2-16 Length Of Hose Adjustment

2-17 Upper Hose Installation

about a two-inch overlap between the hose end and the

the inside of the top to the outside and lock into place.

The hoses in steps 2-17 and 2-18 must be cut to fit your

Remember that the hoses have to be long enough to

ends of the 6” upper hose (Figure 2-19). Then slide one

container inlet. Proceed to slide the opposite end of the

6” hose onto the outlet of the blower assembly. See

Fasten the inlet to the plastic top by sliding the inlet from

machine. Follow steps 2-17 and 2-18. Do not cut the

hose are clearly attached to the inlet and the blower

Figure 2-19

Inlet

Hose

Clamps

Hose

Clamps

Boot

Lower

Hose

Blower

Outlet

Upper

Hose

Blower

Cone

16

3

2

4

5

1

3

5

6

7

8

9

10

12

13

11

14

9Taper-Lock Bushing

Enlarged View

1 - Try carefully hitting the base of the impeller blade

(#1), between each vein (#12), with a rubber mallet to

loosen the taper-lock bushing hold.

To Replace: First, place the impeller blade (#1) over the

drive shaft (#13). Next, slide the taper-lock bushing (#9)

on to the drive shaft and into the impeller blade, aligning

the non-threaded holes (#14) of the taper-lock bushing

to the threaded holes of the impeller blade. Then, fasten

by using two 1/4”-20 x 1” HHCS (#10), one spacer

bushing (#8) one taper lock bushing washer (#7), and

one 3/8”-16 x 1-1/2” HHCS (#6). Torque all bolts to the

specifications located in the chart towards the back of

this manual. Last, rotate the impeller blade to ensure

that the blade is clear of contact on all sides of the

blower housing.

Tips on removing impeller blade;

2 - Spray break-free lubricant into the surrounding areas

of the taper-lock bushing (#9) and repeat Tip 1.

2-20 Impeller Blade

Removal/Replacement

To gain impeller blade (#1) access, first remove the

blower cone (#2) from the blower housing, located on

the PTO assembly P#(A1821), by removing two blower

cone bolts and nuts (#3). Next, remove the blower

housing front (#4) by removing seven bolts and nuts (#5)

around the outer housing edge. Refer to Figure 2-20.

To Remove: First, remove one 3/8”-16 x 1-1/2” HHCS

P#(K1211) (#6), one taper-lock bushing washer

P#(K0278) (#7) and one spacer bushing P#(S3242) (#8)

from the taper-lock bushing (#9). See Figure 2-20. Next,

remove two 1/4”-20 x 1” HHCS (#10) and place them

into the threaded holes (#11) of the taper-lock bushing

P#(S4302). Last, gradually thread each bolt evenly into

the taper-lock bushing, forcing the blade to break-away

from the taper-lock bushing.

Figure 2-20

17

Weight Kit Installation

Review Figure A. Position the Dual Weight Bracket Base (Item#1) under the right caster tubing w/ opening towards

caster fork. Next, position the Weight Bracket Clamp (Item#2) on top of caster tubing w/ opening towards caster fork.

Align the (4) holes of the Weight Bracket Clamp (Item#2) to the holes in the Dual Weight Bracket Base (Item#1).

Loosely fasten the Weight Bracket Clamp (Item#2) to the Weight Bracket Base (Item#1) using (4) 5/16"-18 x 3" Bolts

(Item#4) & (4) 5/16"-18 Ny-Flange Lock Nuts (Item#5).

Position the Weight Bracket Base and the Weight Bracket Clamp assembly along the caster tubing to prevent

interference from caster forks or any other objects. Tighten the fasteners in an 'X’ pattern until assembly is firmly

clamped to caster tubing. Do not over tighten which may result in bending Weight Bracket Clamps (Item#3).

Insert (1) Weight (Item#3) Into the Weight Bracket Base (Item#2) & align the holes of the Weight w/ the holes of the

Weight Bracket Base (Item#2). Fasten the Weight (Item#1) to the Weight Bracket Base Using (1) Clevis Pin (Item#6)

& (1) Hair Pin Clip (Item#7) per weight.

Repeat on right caster with Quad Weight Kit, Figure B

1

2

5

3

4

6

7

Figure A

Item # Part # Desc. Qty.

1 B1014 Dual Weight Bracket / Base 1

2 B1015 Weight Bracket / Clamp 1

3 Y0025 28 lb. Suitcase Weight 2

4 K1472 HHCS 5/16"-18 x 3" GR5 4

5 K2516 Ny-Flange Lock Nut 5/16"-18 4

6 K1473 Clevis Pin 1/2" x 3" 2

7 K1478 Hair Pin Cotter / Double Loop 2

Figure B

18

To empty the bag, first unlatch and lift top, next remove

the bag and bag ring by sliding rearward, then grasp the

loop on the bottom of the bag, and last turn it upside

down to empty the collected debris (Figure 2-22d).

Repeat for the other bags. Reinstall all bags, line with

plastic bags if desired, close the plastic top and reattach

the draw latches.

Plastic lawn and leaf bags, 33 gallon size, may be used

inside the cloth bags. Be sure to leave enough plastic

bag hanging over the frame so the plastic bags can be

twist tied before emptying (Figure 2-22e).

2-22 Installation/Removal Of

Collection Bags

IMPORTANT!

To prevent bag wear, install (2) red plastic end caps

P#(J0274), as shown in Figure 2-22a, on each bag ring

before installing bags.

To install the bag onto the bag ring, place the seam

openings of the bag onto the bag ring openings and turn

the bag one full turn (360 ) so the plastic end caps are

located opposite to the opening in the bag (Figure 2-

22b). Do this for each of three bags.

Install the completed assemblies onto the support frame

and close the plastic top. Fasten both draw-latches to

hold the plastic top closed (Figure 2-22c).

Figure 2-22d

Figure 2-22e

Grasp Bag

Here

Plastic Bag

Cloth Bag

Figure 2-22a

Figure 2-22c

Figure 2-22b

Red Plastic

End Caps

Bag Ring

Bag

Bag Opening

Bag Ring End

Caps Opposite

of Bag Opening

Plastic Top

Fasten Draw

-Latch Here &

Opposite Side

For Proper Unit

Transportation

Completed Bag

Installed

19

20

2

9

4

6

7

10

3

5

8

11

18

17

14

16

15

1

13

12

Item # Doc # Title Qty

1 V0022 PRO 3 BAGGER TOP 1

2 B0676 Hinge Stop Pl. 1

3 K0114 BLACK PLASTIC RIVET 14

4 C0069 DUST GUARD BRACE 1

5 K1030 1/4"-20 x 1-1/4" CARRIAGE BOLT 2

6 J4009 SHORT RUBBER STRAP W/ S HOOK 2

7 K0037 1/4" FLAT WASHER .75 OD x .314 ID x .060 T 2

8 K1128 1/4"-20 NYLOC NUT 2

9 C0026 GRASS DEFLECTOR 1

10 K0062 3/16" x 1-1/2" FENDER WASHER, Z 4

11 K1265 BLACK PANEL RETAINER 3

12 V1120 Black Plastic Screen 1

13 V1118 DUST GUARD 1

14 R1057 2" x 4" Red Reflector Label 2

15 R1069 Warning - Turn Off Blower Label 1

16 R1065 Made In USA Label 1

17 R1054 Important Check Hoses 1

18 R1051 Warning - Use Hearing Protection 1

Exploded Parts View

A1190 Top Assembly

Table of contents

Other Country Clipper Lawn Mower Accessories manuals