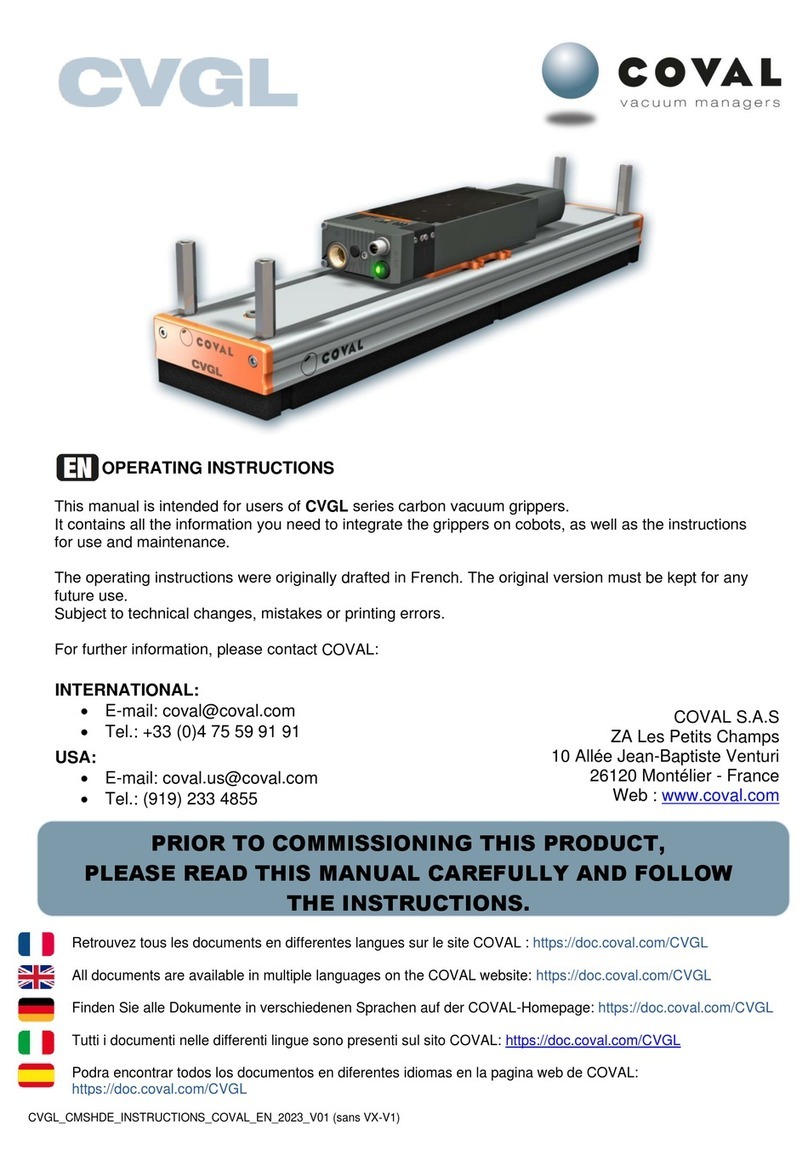

1. IMPORTANT INFORMATION

This document contains important instructions and information regarding the product’s various operational

phases:

. Transport, storage, commissioning and decommissioning

. Use and maintenance

The operating instructions correspond to the product actually delivered.

This document is part of the product and the following information must be observed:

. Please carefully read this document and observe the instructions to ensure safe installation, optimal

operation of the product and to avoid any malfunction

. Please keep the document within reach of the product so that the staff can easily access it.

Important:

. Failure to observe the instructions specified in this document may lead to injury or even death!

. COVAL will not be held liable for any damage or breakdown as a consequence of failure to observe

instructions.

For any additional information, please contact COVAL:

. Tel: +33 (0)4 75 59 91 91

2. INSTRUCTIONS FOR USE AND SAFETY

2.1. ASSEMBLY/DISASSEMBLY

Only qualified personnel is authorized to use the components. Such personnel must be trained in the following

areas:

. Applicable safety rules and requirements for using components and installing them in devices, machines and

machine lines

. Appropriate handling of components and their respective products

. Proper use with the operating materials

. The latest applicable EC directives, legislations, decrees and standards, as well as the current state of the art

The improper use of components with other operating materials than those defined, other voltages and under

other environmental conditions

can lead to failure, damage and injury.

This list is considered as an overview and does not claim to be exhaustive. Users can complement it

according to their particular needs.

2.2. SAFETY INSTRUCTIONS

In order to ensure flawless installation and operation, the following rules must also be observed:

. The components must be carefully removed from their packaging.

. The components must be protected against any and all damage.

. During installation and maintenance work, remove the voltage and pressure from the Venturi pump and

ensure that unauthorized personnel cannot restart it.

. Any attempt to alter the components is strictly prohibited.

. The area surrounding the components and the location where used must be kept clean.

. Standing under the payload being handled by the vacuum pump and in its pathway is strictly prohibited.

. Only the fittings/connectors provided may be used.

. During installation, only use flexible tubes and tubes that are suitable for the specific operating material

(tubes that come loose or electrical connection lines constitute a major safety hazard—including risk of

death!).

. Conductive and live cables lines must be insulated, of appropriate size, and properly installed.

. Pneumatic and electric lines must be connected to the component in a stable and safe manner.

. Prevent any physical contact with electric parts (protect electrical contacts).

. Only use the available fastening means described in section 6.5.