FUNCTION

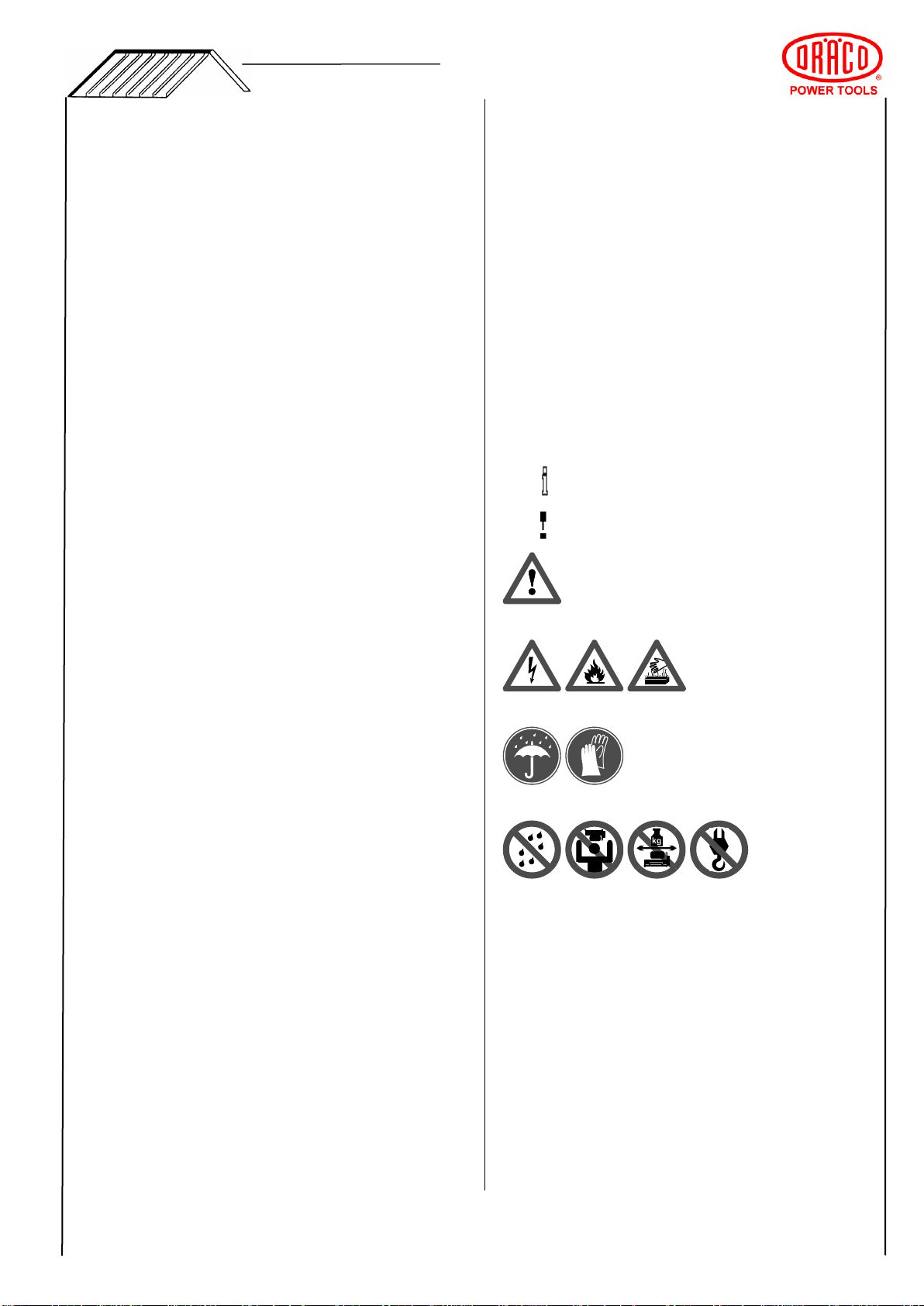

Power Seamer K9-1-WAD is a new combination of

DRÄCO patented functions all together, to close a

single-, or double lock seam, cutting rolls K9-1-AR

set, to cut the seam open for renovation or repair at

the roof or wall.

Seamer K9-1 or K9-1-WAD is a light weighted

machine at an advanced working speed between

5,5 - 13 meter per minute. A seam at the wall 90

degrees up or down can be handled without a

problem. All materials can be closed to a seam in a

clean transition, also at cross seams.

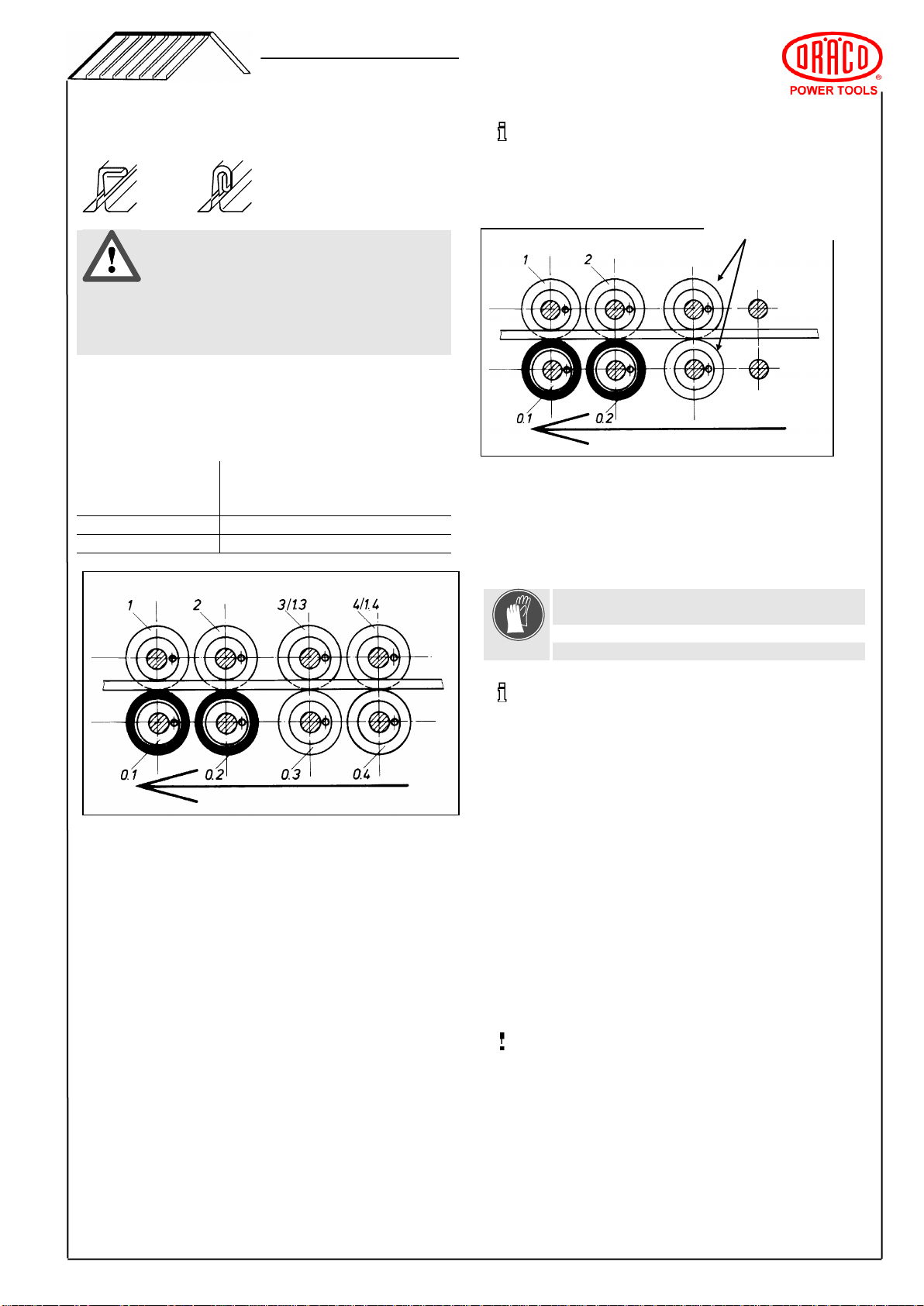

The high seam quality is achieved through 8 drive

rolls. Two rubber drive rolls work, without leaving

scratch marks on painted or coated sheets, up to 0,8

mm, and stainless steel 0,6 mm in thickness.

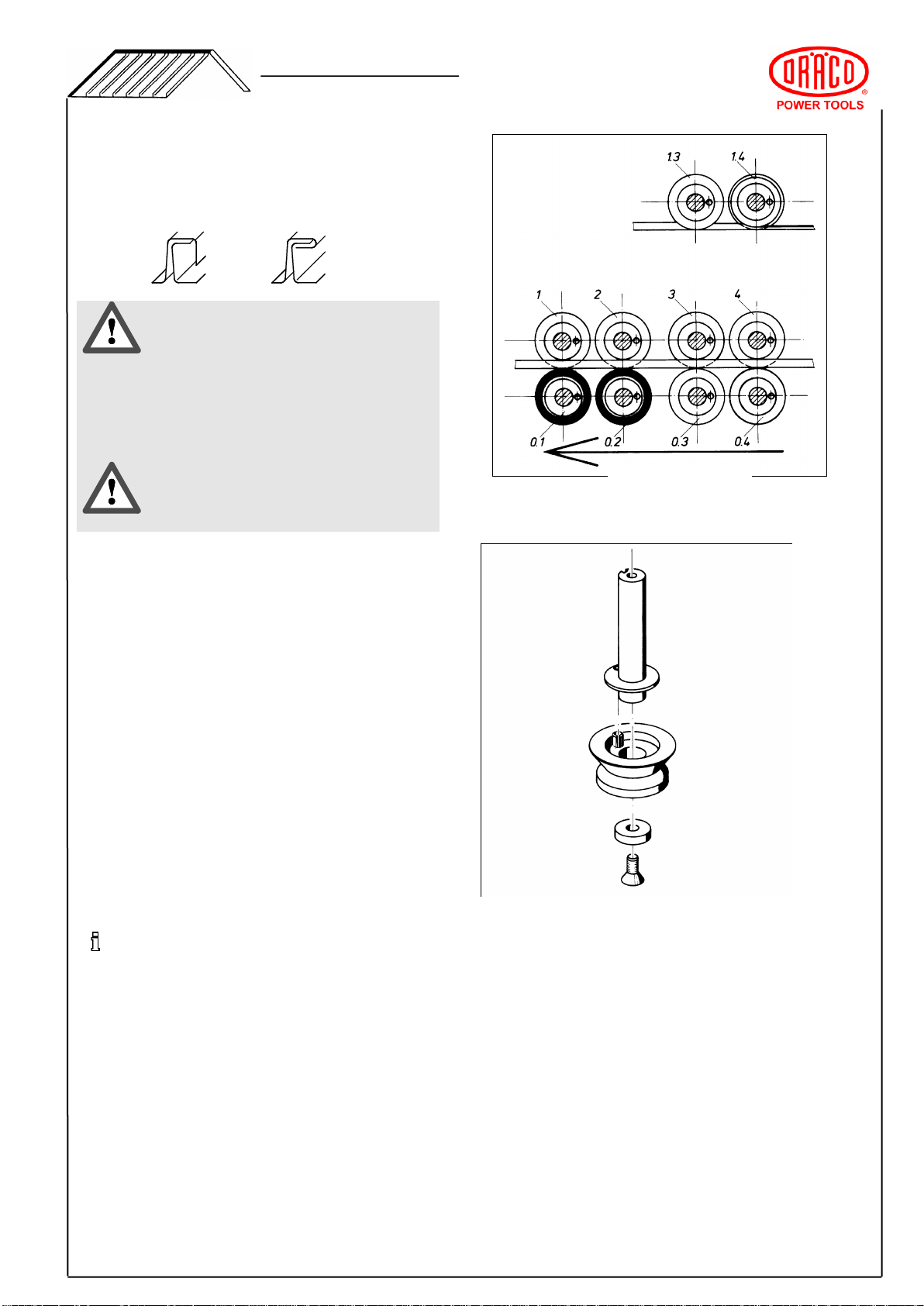

Four outrigger wheels can be adjusted for different

seam heights from 25 to 60 mm. The variable

pressure adjustment K9-1-ASS can be adjusted to

achieve an optimum closed seam.

To close barrel curved roofs, a radius of 2 meter is

possible without any adjustment. A brass-washer

under forming stations No. 1 and No. 1.4 minimizes

the radius to 1,2 meter. Clean transition at the clips

and cross seams due to the spring washers and the

variable pressure adjustment K9-1-ASS.

Seamer K9-1 version closes the profiled panels to a

double lock seam. Multifunctional accessories are:

single lock forming rolls K9-1-WR, dual safety switch

K9-1-DF, set of cutting rolls K9-1-AR, winter set K9-

1-WS, remote control K9-1-KF.

For recycling or repairing a panel at the roof or wall,

the cutting rolls K9-1-AR can be mounted to the

seamer to cut open the single or double lock seam.

Lifting eyes are assembled to the seamer to enable

a safety rope or cable to be fitted, especially when

working on vertical claddings or on a steep slope on

top of the roof. Overhead working with the seamer is

not allowed.

Safety first on site, roof or wall is our endeavor, the

patented dual safety switch K9-1-DF prevents the

seamer to fall off the roof, stops automatically at the

end of a seam, gutter or ridge, wall or obstructions.

Winter Set K9-1-WS, attached to the seamer and

speed control in low working speed, (under + 10°C)

for trouble free seaming in cold temperatures. Ideal

for best results in seaming.

CONTENTS

Please check package for completeness.

BASIC EQUIPMENT:

◼1 Power Seamer K9- 1, for double lock seam

◼1 Manual

◼1 Transport box

◼1 Allen Key

◼2 Spare Screws

Assembled:

◼Variable Speed Control

◼Variable Pressure Adjustment System K9-1-ASS

◼Socket for Dual –Safety Switch K9-1-DF

◼Socket for Remote Control K9-1-KF with

FORWARD-STOP-REVERSE-Function

Accessories for K9-1

(Not included in Basic equipment)

◼Set Forming Rolls Single Seam K9-1-WR

◼Set Of Cutting Rolls K9-1-AR

◼Dual Safety Switch K9-1-DF

◼Remote Control K9-1-KF

◼Winter Set K9-1-WS

◼Hand Seamer K8 Single Lock

◼Hand Seamer K7 Double Lock

Remote Control Information (option)

The remote control for forward and reverse

operation

is ideal to close the single lock seam at the facade

or wall from the ground, comfortable.

Attention

A double lock seam can only be closed in forward

operation. Reverse operation of seamer a knot will

be between the single and double lock seam. To

avoid the knot, open the locking handle move

seamer about 30 cm backwards until the seamer is

stationed above the double lock seam, close the

locking handle again and switch to reverse