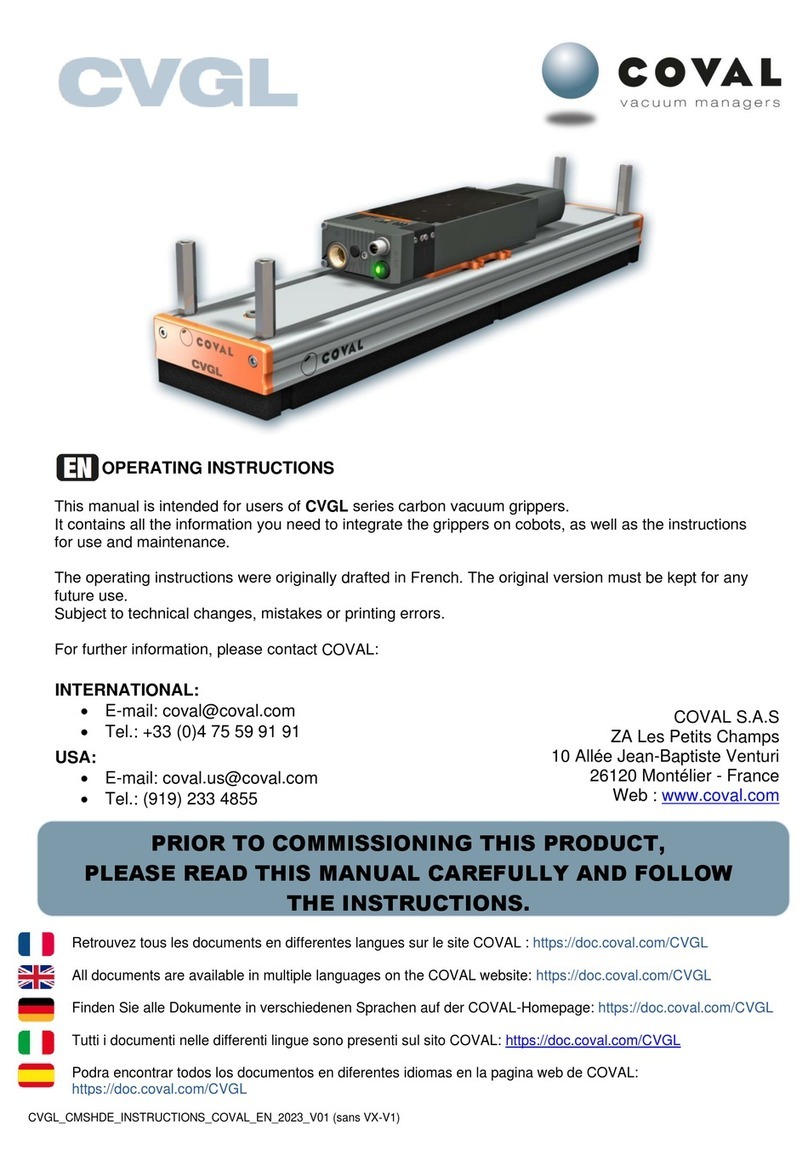

coval CVGL User manual

Retrouvez tous les documents en différentes langues sur le site COVAL : https://doc.coval.com/CVGL

All documents are available in multiple languages on the COVAL website: https://doc.coval.com/CVGL

Finden Sie alle Dokumente in verschiedenen Sprachen auf der COVAL-Homepage: https://doc.coval.com/CVGL

Tutti i documenti nelle differenti lingue sono presenti sul sito COVAL: https://doc.coval.com/CVGL

Podrá encontrar todos los documentos en diferentes idiomas en la página web de COVAL: https://doc.coval.com/CVGL

CVGL

Compact and Light Vacuum Grippers

OPERATING INSTRUCTIONS

This manual is intended for users of CVGL series vacuum

grippers.

It contains all the information you need to integrate the grippers,

as well as the instructions for use and maintenance.

The operating instructions were originally drafted in French

(original version).

They must be kept for any future use.

Subject to technical changes, mistakes or printing errors.

For any additional information, please contact COVAL:

International:

E-mail: coval@coval.com

Tel: +33 (0)4 75 59 91 91

COVAL S.A.S. (Head Office)

ZA Les Petits Champs

10 allée Jean-Baptiste Venturi

26120 Montélier France

Web : www.coval.com

USA:

E-mail: contact.us@coval.com

Tel: (919) 233 4855

COVAL VACUUM TECHNOLOGY INC.

901 Jones Franklin Road

Suite 100

Raleigh, NC 27606

Web: www.coval-inc.com

CVGL_CMSHDE_INSTRUCTIONS_COVAL_EN_2023_V1.03

PRIOR TO COMMISSIONING THIS PRODUCT,

PLEASE CAREFULLY READ THIS MANUAL AND FOLLOW THE INSTRUCTIONS.

EN

-2-

www.coval.com

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

SUMMARY

1. IMPORTANT INFORMATION ......................................................................... 3

2. SAFETY INSTRUCTIONS............................................................................. 3

3. INSTRUCTIONS FOR USE............................................................................ 4

3.1. Basic Installation ..........................................................................................4

3.2. Commissioning and Decommissioning.....................................................4

3.3. Operating the Vacuum Gripper..................................................................5

3.4. Transportation and Storage.......................................................................5

3.5. Maintenance..................................................................................................5

3.6. Disposal.........................................................................................................5

4. NAMEPLATE ............................................................................................... 5

5. IDENTIFYING YOUR MODEL........................................................................ 6

6. TECHNOLOGIES USED................................................................................ 8

6.1. Gripping Interface.........................................................................................8

6.2. Flow Control Technologies..........................................................................9

7. OVERVIEW, DIMENSIONS, AND MOUNTING ................................................ 9

7.1. Overview .........................................................................................................9

7.2. Dimensions and Mounting Options .......................................................... 10

7.3. Gripping Interface Dimensions .................................................................12

8. CHARACTERISTICS....................................................................................13

9. INSTALLING THE VACUUM GRIPPER .........................................................14

9.1. Pneumatic Supply for Vacuum Grippers Equipped with One or More

CMS HDE Vacuum Generators...........................................................................14

9.2. Pneumatic Connection...............................................................................14

9.2.1. CVGL Versions D1 and D2............................................................................................. 15

9.2.2. CVGL Version D3........................................................................................................... 15

9.2.3. CVGL Version G0........................................................................................................... 15

9.3. Connecting a Vacuum Switch ...................................................................16

9.4. Electrical Connections: CVGL with Vacuum Generator Control

(versions S and V)...............................................................................................16

9.5. CVGL with Vacuum Level Display (Versions VA and VF).........................17

10. INSTALLING AND OPERATING REMOTE HMI (CVGL VERSION VI)............ 17

10.1. Dimensions..................................................................................................17

10.2. Installing the Remote HMI, part no. HMIHD1M84P..................................18

10.3. Conguring a Remote HMI........................................................................18

10.4. Front Panel Dialog .....................................................................................19

11. HMI DETAILS AND FEATURES ...................................................................19

11.1. Powering On .................................................................................................19

11.2. Details of the Main Screen ........................................................................19

11.3. Keypad Functions......................................................................................20

12. SUMMARY OF FUNCTIONS ......................................................................20

12.1. Accessing Live Diagnostic Data ..............................................................20

12.2. Menu Tree....................................................................................................21

13. LOCKING/UNLOCKING THE KEYPAD....................................................... 22

14. PROCESS SETTINGS ............................................................................... 22

14.1. Setting Threshold 1....................................................................................22

14.2. Auto Blow-off.............................................................................................23

15. USER SETTINGS...................................................................................... 23

15.1. Language ....................................................................................................23

15.2. Screen.........................................................................................................23

15.3. Units............................................................................................................23

16. DEVICE SETTINGS...................................................................................24

16.1. Input/Output Switching Mode: PNP or NPN ...........................................24

16.2. NO / NC.......................................................................................................24

17. DIAGNOSTICS ..........................................................................................24

17.1. Device Info..................................................................................................24

17.2. Cycle Counters...........................................................................................24

17.3. Manual Mode...............................................................................................25

17.4. Calibration..................................................................................................25

17.5. Reset Settings............................................................................................26

18. EVENTS AND ALARMS ............................................................................ 26

19. IO-LINK PARAMETER SETTINGS............................................................. 27

19.1. IO-Link Communication............................................................................27

19.2. Cyclical Data (PDI/PDO)............................................................................27

19.3. Acyclical Data............................................................................................28

20. NFC......................................................................................................... 29

20.1. Technical Data ..........................................................................................29

20.2. Using NFC..................................................................................................29

20.3. Functionality.............................................................................................30

20.4. Downloading the COVAL VACUUM MANAGER NFC App .........................30

21. OPERATING THE VACUUM GRIPPER........................................................ 30

21.1. Version with Foam Gripping Interface....................................................30

21.1.1. Version with foam and ow control technology using valves............................. 31

21.1.2. Version with foam and ow control technology using ow control nozzle.... 32

21.2. Version with Suction Cup Gripping Interface .......................................33

21.3. Version with COVAL-ex Gripping Interface .........................................34

22. MAINTENANCE ....................................................................................... 35

22.1. Frequency ..................................................................................................35

22.2. Assembling/Disassembling Gripping Interfaces .................................36

22.3. Replacing the Gripping Foam.................................................................36

22.4. Replacing Suction Cups ..........................................................................37

22.5. Disassembling the CMS HDE Series Vacuum Generator.....................37

22.6. Maintenance Procedures for a Vacuum Generator,

CMS HDE Series..................................................................................................38

22.6.1. Cleaning the lter screen on the compressed air supply................................. 38

22.6.2. Cleaning the vacuum lter and the vacuum check valve................................ 38

22.6.3.Cleaning the multi-stage venturi proles ............................................................40

22.6.4. Replacing the solenoid valves................................................................................. 41

22.6.5. Replacing the pressure connection end plate for CMSHDE90X__NVO............ 41

22.6.6. Replacing the valve block for CMSHDE90X__SVOC15P / VVOC15P

and CMSHDE90X__SVX_ / VVX_............................................................................................ 41

22.6.7. Replacing the exhaust silencer.............................................................................. 42

22.7. Performing Airtightness Test on Vacuum Gripper...............................42

23. SPARE PARTS......................................................................................... 43

23.1. Foam Gripping Interface..........................................................................43

23.1.1. Complete spare foam gripping interface.............................................................. 43

23.1.2. Spare foam bases ..................................................................................................... 44

23.2. Suction Cup Gripping Interfaces ...........................................................44

23.2.1. Complete replacement suction cup gripping interface.................................... 44

23.2.2. Spare suction cups .................................................................................................. 45

23.3. CMS HDE Series Multi-Stage Vacuum Generators

for CVGL___D1, D2, or D3...................................................................................46

23.4. Spare Parts for CMS HDE Series Vacuum Generators........................46

23.5. Vacuum Switch and Vacuum Gauge .....................................................50

23.6. Accessories...............................................................................................50

24. GLOSSARY.............................................................................................. 50

25. WARRANTY.............................................................................................50

26. RECYCLING.............................................................................................50

27. DECLARATION OF CONFORMITY..............................................................51

-3-

www.coval.com

1. IMPORTANT INFORMATION

This document contains important instructions and information regarding various stages in the life cycle of the product:

Transportation, storage, commissioning, and decommissioning.

Operation and service.

The operating instructions correspond to the product actually delivered.

This document is part of the product and the instructions below must be followed:

Read this document carefully and observe the instructions to ensure safe installation, optimal operation of the product, and to avoid

any malfunction.

Keep the document within reach of the product so operators can easily access it.

Failure to observe the instructions specied in this document may lead to injury or even death!

COVAL will not be held liable for any damage or breakdown resulting from failure to follow instructions.

For any additional information, please contact COVAL:

International: USA:

E-mail: coval@coval.com E-mail: contact.us@coval.com

Tel.: +33 (0)4 75 59 91 91 Tel: (919) 233 4855

2. SAFETY INSTRUCTIONS

Only qualied personnel should be authorized to use the components. These individuals must be trained in the following areas:

Installing pneumatic and electric equipment.

Applicable safety rules and requirements for using components and installing them in devices, machines, and production lines.

Appropriate handling of components and their respective products.

Proper use of the operating materials and supplies.

The latest applicable EC directives, legislations, decrees, and standards, as well as the current state of the technology for its intended

use.

Any special measures necessary to meet these requirements, as well as the current state of the technology.

Installation in a secure environment.

The vacuum gripper is solely intended for use in automated applications and in secure areas.

The improper use of components, use of operating materials and supplies other than those dened, improper voltages, and/or other

environmental conditions may lead to failure, damage, and/or injury.

This list must be considered as an overview and does not claim to be exhaustive. It can be further expanded by users according to their

particular needs.

NOTE:

This document provides detailed operating instructions for the standard models referenced in chapter 5. For custom models, the

information herein must be adapted to the specific features of the product. Custom versions are products that have been tailored to

meet the constraints of a specific application. The following are examples of such custom models:

Different product lengths

Multi-zone

Different suction cups

Different accessories

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-4-

www.coval.com

HAZARD AREAS

Area where there is a risk of crushing Area where there is a risk of air ejection

Notes for the manufacturer of the nal machinery and for the end user

Standing or walking in the operating area of the vacuum gripper is strictly prohibited. In the event of a power or pneumatic supply

failure, the load handled by the gripper will be released.

Never look inside and/or introduce hands into cavities, holes, or openings (e.g. air exhausts, openings/holes under the suction cups,

etc.).

The vacuum gripper described in this manual is designed for implementation in industrial systems. In other words, It must not be used

under any conditions other than those specied.

Once the vacuum gripper is installed, the manufacturer of the nal machinery is responsible for the nal assessment of safety systems

applied prior to putting the facility into operation. It is the responsibility of the manufacturer of the nal machinery to specify the

PPE required for operators standing in the vicinity as well as for those who have access to the operating area. Furthermore, the said

manufacturer must certify nal commissioning in accordance with applicable local rules and regulations.

3. INSTRUCTIONS FOR USE

3.1. Basic Installation

In order to ensure awless installation and operation, the following rules must also be observed:

Vacuum grippers must be carefully removed from their packaging.

Vacuum grippers must be protected against any and all damage.

During installation and maintenance work, the vacuum generator must be de-energized (air and power) and secured against any

unauthorized activation.

Any attempt to alter the vacuum gripper is strictly prohibited.

The area surrounding the vacuum gripper and the location where it is used must be kept clean (no outdoor use).

Only the ttings/connectors provided may be used.

During installation, only exible tubes and tubes that are suitable for the specic operating material may be used (Improper tubing and/

or electrical lines are a major safety hazard- including risk of death!).

Conductive and live cable lines must be insulated, of an adequate size, and properly installed.

Pneumatic and electric lines must be connected to the component in a stable and safe manner.

Ensure that any physical contact with electric parts is prevented (protect electrical contacts).

Only available fastening means described in this document maybe used and tightening torques must be used accordingly.

The possibility of power or pneumatic supply interruption must be taken into consideration to ensure people and systems are protected

at all times.

Emergency stops should be accounted for when designing the system.

3.2. Commissioning and Decommissioning

Commissioning:

Ensure the exible tubes for compressed air and power supply are connected correctly using the appropriate connectors.

Decommissioning (prior to any disassembly or maintenance work):

Ensure the gripper is not holding any objects (load may drop).

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-5-

www.coval.com

XXXXXXXXXXXXXXXX…

CVGL424DVSA33JKXHXD1S1KVA

2,520 KG

www.coval.com

Intended use

The vacuum gripper is solely intended for use in automated applications and in secure areas.

Use cases depend on the gripping interfaces used see chapter 6.

Unintended use

The vacuum gripper may not be used for the following:

Manual applications.

Uses other than those established by the manufacturer or specied in this manual.

In direct contact with hazardous materials (molten masses, radioactive products), water, steam, or in environments where

dripping or splashing water, oil, etc. may occur.

In explosive, acidic, alkaline, or saline atmospheres.

In environments subject to strong vibrations and/or shocks.

3.3. Operating the Vacuum Gripper

3.4. Transportation and Storage

When handling the vacuum gripper, only use equipment that is suitable for its dimensions and weight.

For proper storage of the system and its spare parts, we recommend the following:

Do not store in outdoor areas or areas exposed to bad weather, excessive moisture, or direct sunlight

In a reasonably clean environment, place the system in such a way that it rests on a stable support base, and ensure that the device

cannot tip over.

Store the gripper in a manner where the interface is uncompressed.

3.5. Maintenance

Maintenance must be performed in accordance with the instructions in this manual. Prior to performing any maintenance work, follow the

instrutions provided in section 3.2.

3.6. Disposal

When disposing of the system or any of its constituent parts that are no longer functional, follow the procedure below:

Waste electrical and electronic equipment (WEEE) must not be disposed of in urban waste collection bins but given to the

appropriate recycling organization (see section 26 on RECYCLING).

Failure to observe the above safety instructions may lead to failure, damage, and injury—even risk of death.

The components of the device that are no longer in working order must be recycled in an environmentally-

friendly manner!

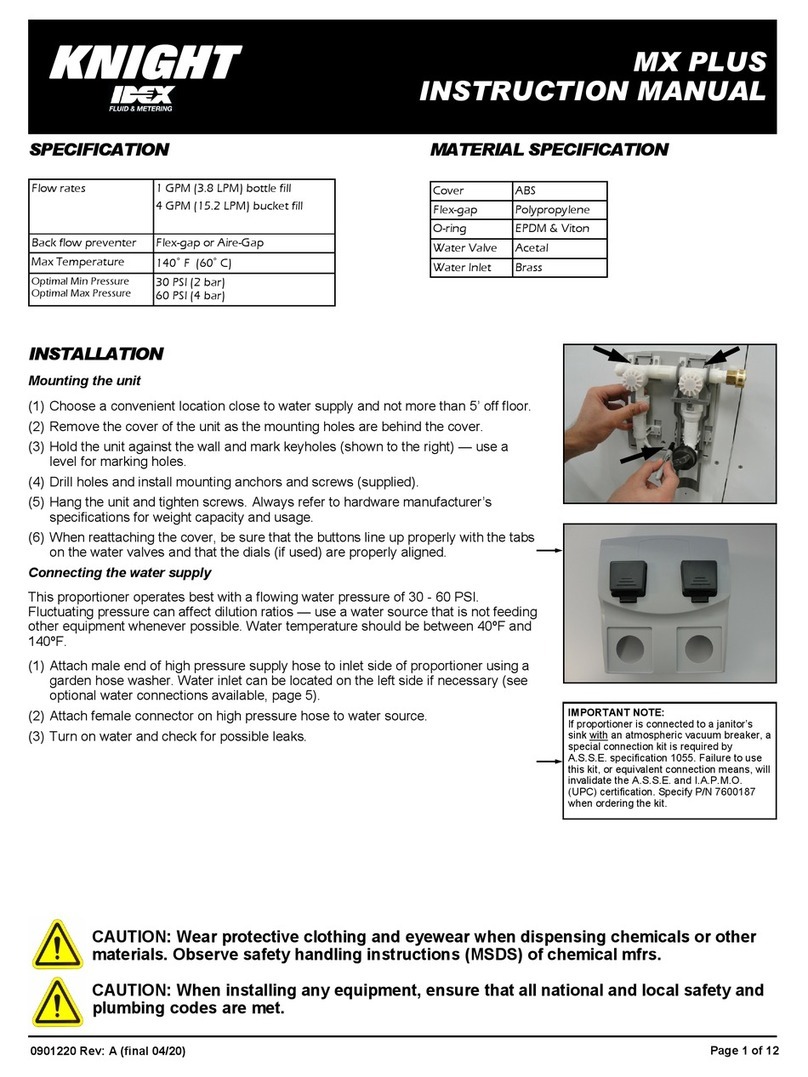

Sample nameplate

4. NAMEPLATE

The nameplate is axed to the vacuum gripper in such a way that it is legible at all times.

It includes the following information:

Part number

Serial number

Weight

CE marking

UKCA marking.

Always provide the part and serial numbers of the product when you contact COVAL.

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-6-

www.coval.com

CVGL 424 D VSA33JK X H X D1 S 1 KVA

424

624

824

X H

Q

D

VSP14BF

VSA25JI

VSA33JK

MVS30EK

X

C

X

F

H

E

V

F2S

F2B

OVERALL LENGTH

424 mm

624 mm

824 mm

HOLE/CUP

PATTERN LAYOUT

Staggered

Straight*

* Only available for "maxi" type gripping interface

with minimum suction cup Ø 26mm.

"COVAL-flex" gripping interfaces are designed to respond to specific

applications. Our vacuum team will recommend and define any applications of

yours which can benefit from its special features.

SPECIAL VERSIONS

There can be instances where the standard CVGL versions will not match your application requirements.

COVAL can provide you personalized solutions based on your specifications, by integrating specific function and suggesting custom

lengths and suction cup types.

ASSEMBLY

TYPE

Screw mounting

Quick-mounting

spring clips

FILTER

Without

TECHNOLOGY

Flow control

nozzles

SUCTION CUPS GRIPPING INTERFACES

"mini" type interface:

2.5 bellows suction cups Ø 14 mm in

silicone 30 Shore with flow control nozzles

"medium" type interface:

1.5 bellows suction cups Ø 25 mm in

natural rubber with flow control nozzles.

"maxi" type interface:

1.5 bellows suction cups Ø 33 mm in

natural rubber with flow control nozzles.

"maxi" type interface:

2.5 bellows suction cups Ø 30 mm in

white silicone 35 Shore with flow control nozzles.

FILTER

Without

With

filter

TECHNOLOGY

Flow control

nozzles

Airtight valves

Check valves

FOAM GRIPPING INTERFACES

Foam "mini" type interface:

EPDM (thickness 20 mm)

Foam "maxi" type interface:

EPDM (thickness 20 mm)

GRIPPING INTERFACES

5. IDENTIFYING YOUR MODEL

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-7-

www.coval.com

D1 S 1 KVA

G0

D1

D2

D3

VO

VA

VF

VI

X

K

N

N

S*

V*

0

0

1

2

* Only for D1 and D2.

VERSION WITHOUT

VACUUM GENERATOR

Without

vacuum generator

VERSIONS WITH

VACUUM GENERATOR*

1 x CMSHDE_50

multi-stage vacuum pump

Flow rate: 700 Nl/min

1 x CMSHDE_100

multi-stage vacuum pump

Flow rate: 1100 Nl/min

2 x CMSHDE_100

multi-stage vacuum pump

Flow rate: 2200 Nl/min

VACUUM LEVEL DISPLAY

Without

Vacuum switch with electronic display

Vacuum gauge

(for versions with control,

option available for 624 mm in length and longer)

HMI on CMS HDE

(compatible with S2 and V2 versions only)

EXHAUST

Without

EXHAUST

Through-type

silencer

GENERATOR

CONTROL

Without

GENERATOR

CONTROL

Without

CMSHDE__S_

Vacuum pump with

NC vacuum control

and NC blow-off

control.

Choice of blow-off

settings (only on

CVGL__S2_models):

Controlled by

external signal

Automatic timer

from 50 to 9999 ms

(advantage: saves

one controller

output).

CMSHDE__V_

Vacuum pump with

NO vacuum control

and NC blow-off

control.

Blow-off controlled

by external signal

GENERATOR

CONFIGURATION

Without

GENERATOR

CONFIGURATION

Without

CMSHDE____VOC15P_

Multi-stage vacuum

pump without vacuum

switch and HMI

One M12 5-pin male

PNP

Digital inputs/

outputs mode (SIO)

CMSHDE____VXC15X_

Multi-stage vacuum

pump with integrated

vacuum switch and

pressure sensor,

without HMI

One M12 5-pin male

configurable as

PNP or NPN

One M8 4-pin male

for remote HMI

Electronic vacuum

switch

Digital Output DO1

"object gripped" 24

V DC / NO

Digital input/outputs

mode (SIO) /

Compatible with

HMI (for VI option)

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-8-

www.coval.com

6. TECHNOLOGIES USED

6.1. Gripping Interface

With CVGL, COVAL gives you a choice of 3 complementary gripping interface technologies: vacuum grippers with foam, suction cup

grippers, and grippers with a COVAL-ex interface.

In order to optimize the performance of the CVGL series for different applications, the vacuum grippers are available in different gripping

patterns, hole diameters, and cup sizes.

A broad range which meets all application requirements.

"FOAM" Interface

Handling of rigid products.

Gripping textured or uneven surfaces.

Flow control nozzles, airtight valves, or

check valves.

2 standard hole diameters (Ø 12, 16mm).

2 standard hole patterns.

3 standard lengths (424, 624, and 824mm)

or custom length.

"SUCTION CUP" Interface

Handling of exible products.

Wide range of cup options.

Flow control nozzles in multiple

diameters.

4 types of standard suction cups (Ø 14,

Ø25, Ø 30 and Ø 33 mm).

3 standard cup patterns.

3 standard lengths (424, 624, and 824mm)

or custom length.

"COVAL-ex" Interface

Handling of aluminum cans, canned food,

glass containers, etc.

Flexible interface, extremely tear-

resistant.

Hole pattern dependent upon application

requirements, completely customizable.

"MINI" type

Reduced hole spacing, allowing small,

exible pieces to be gripped.

The multitude of gripping points

guarantees a strong grip, even with

random positioning of products.

"MEDIUM" type

An intermediate distribution of gripping

points between the "mini" and "maxi" type.

Ideal for handling dense loads with

reduced gripping surface.

"MAXI" type

Large gripping point surfaces, allowing

heavy loads to be gripped.

Ideal for gripping parts with rigid gripping

surfaces.

Standard Hole/Cup Patterns

In order to optimize the performance of the CVGL series for different applications, the vacuum grippers are available in different gripping

patterns, hole diameters, and cup sizes.

Part number Total length of the vacuum gripper (mm) Force at 80% vacuum* (N) / (lbf) Force at 45% vacuum* (N) / (lbf)

CVGL 424_ _ _ _ 424 1035 / 232.6 600 / 134.9

CVGL 624_ _ _ _ 624 1550 / 348.4 900 / 202.3

CVGL 824_ _ _ _ 824 2070 / 465.3 1200 / 269.8

Vacuum Gripping Force

* Indicative force for a vacuum gripper 100% covered by the load, without safety factor, on a rigid and airtight surface.

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-9-

www.coval.com

6.2. Flow Control Technologies

COVAL offers 3 ow control technologies to optimize your vacuum gripper and perfectly respond to the constraints of your application.

CMS HDE series

integrated vacuum generator

"Suction cup"

Gripping Interfaces:

wide range of suction

cups (shapes, diameters,

materials, etc.)

"Foam"

Gripping Interfaces

G1"-F connection for

external vacuum generator

(electric or pneumatic)

Gripper optimization

with ow control

technologies

Extra-thin aluminum prole with

T-shaped lateral groove.

LENGTH: 424, 624, or 824 mm

Flexible

Gripping Interface

Vacuum display:

HMI

vacuum gauge

electronic vacuum switch

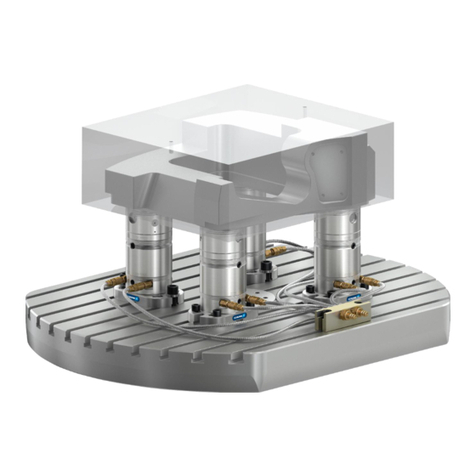

7. OVERVIEW, DIMENSIONS, AND MOUNTING

7.1. Overview

Flow control nozzles

Limits the leakage rate of uncovered

zones.

Economical solution.

Customizable calibration.

Horizontal and vertical handling.

Airtight valves (COVAL patent)

Isolates uncovered zones.

Provides energy savings.

Meets specic needs.

Instant gripping.

Quick release to blow-off.

Horizontal handling.

Check valves (COVAL patent)

Limits the leakage rate of uncovered

zones.

Instant gripping.

High versatility of applications.

Quick release to blow-off.

Horizontal handling.

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-10-

www.coval.com

91.5

56.535

120

50

98

G3/8"-F

284

18

DC

E18 F

M8

83

83

A

B

A

120

98

91.5

56.535

83

B

50

G1"-F

50

M8

CVGL424 CVGL624 CVGL824

A424 624 824

B408 608 808

7.2. Dimensions and Mounting Options

COVAL CVGL series vacuum grippers can be mounted on all types of automated or robotic systems,

using M8 spacers that slide in the grooves of the aluminum prole.

Permissible tightening torque on spacers: 20 N m max.

Dimensions

CVGL 424 and 624: 4 x M8 spacers.

CVGL 824: 8 x M8 spacers.

Permissible tightening torques:

Spacers: 20 N m

G1" vacuum connection: 25 N m

VERSION G0 (with external vacuum generator)

adjustable

position

adjustable

position

adjustable

position

vacuum switch

connection G1/8"-F

vacuum switch

connection G1/8"-F

CVGL424 CVGL624 CVGL824

A424 624 824

B408 608 808

C15 134 233

D125 207 307

E76 194 294

F116 198 298

Dimensions

CVGL 424 and 624: 4 x M8 spacers

CVGL 824: 8 x M8 spacers

Permissible tightening torques:

Spacers: 20 N m

G3/8” pressure connection: 10 N m

VERSIONS D1 or D2 without control (1 integrated CMS HDE series vacuum generator)

Note: all dimensions are in mm.

M8 spacers

with M8 slide nuts

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-11-

www.coval.com

91.5

56.535

120

50

98

G3/8"-F

330

18

DC

E18 F

M8

83

83

A

B

91.5

56.535

412

808

284 90

18

284 8383

153.5 23818 153.5

M8

83

120

98

G3/8"-F

83

824

CVGL424CVGL624CVGL824

A424 624 824

B408 608 808

C15 134 234

D78 160 260

E76 194 294

F47 129 229

CVGL 424 and 624: 4 x M8 spacers

CVGL 824: 8 x M8 spacers

Permissible tightening torques:

Spacers: 20 N m

G3/8” pressure connection: 10 N m

VERSIONS D1 or D2 with control (1 integrated CMS HDE series vacuum generator)

Dimensions

adjustable

position adjustable

position

vacuum switch

connection G1/8"-F

adjustable

position

adjustable

position

adjustable

position

vacuum switch connection G1/8"-F

CVGL 824: 6 x M8 spacers Permissible tightening torques:

Spacers: 20 N m

2 x G3/8” pressure connection: 10 N m

VERSION D3 (2 integrated CMS HDE series vacuum generators)

Note: all dimensions are in mm.

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-12-

www.coval.com

29

120

12 (f)

51.2

120

17.5 (f)

Ø 25

18

20

38.5

40

Ø 30

25

120

9 (f)

32.5

120

11 (f)

Ø 14

18.8

15

38.5

40

Ø 33

51.2

120

17.5 (f)

32.5

120

11 (f)

28

24

Ø 33

28

24

Ø 30

22.5

20

Ø 12

20

15(f)

120

20

15(f)

120

21

40

Ø 16

6

120

120 10

120

3.3

7.3. Gripping Interface Dimensions

CVGL424 CVGL624 CVGL824

"mini" type gripping interface Ø12 mm 98 148 198

"maxi" type gripping interface Ø16 mm 50 75 100

CVGL424 CVGL624 CVGL824

"Mini" type suction cup Ø14 mm

(Ø16 mm max.) 150 220 297

"Medium" type suction cup Ø25 mm

(Ø18 to 25 mm) 55 83 113

"Maxi" type, STRAIGHT pattern Ø30 or

Ø33 mm suction cups (Ø36 mm max.) 33 48 63

"Maxi" type, STAGGERED pattern Ø30 or

Ø33 mm suction cups (Ø36 mm max.) 28 42 58

model VSA33

model VSA33

"MINI" type suction cup

gripping interface

"MINI" type foam

gripping interface

"MEDIUM" type suction

cup gripping interface

"MAXI" type foam

gripping interface

model MVS30

model MVS30

"MAXI" type suction cup gripping interface, STRAIGHT PATTERN

"MAXI" type suction cup gripping interface, STAGGERED PATTERN

f: foam compressionf: suction cup deection

SUCTION CUP GRIPPING INTERFACE FOAM GRIPPING INTERFACE

NUMBER OF GRIPPING

POINTS PER INTERFACE

NUMBER OF SUCTION CUPS

PER GRIPPING INTERFACE

Option: HMI integrated on generator

Option: CVGL ____VI

Note: all dimensions are in mm.

COVAL-ex GRIPPING INTERFACE

Option: quick installation of the interface

Option: CVGL____C__

quick installation of the

interface via spring clips

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-13-

www.coval.com

General Characteristics

Temperature: from 0 to 50°C (32 to 122° F).

Material of the gripper: aluminum, PA 6.6 15% GF, brass, stainless steel,

neoprene.

Foam gripping interface material: EPDM.

Suction cup gripping interface materials:

- "mini" type interface: silicone 30 Shore.

- "medium" type interfaces: natural rubber 50 Shore.

- "maxi" type interfaces: natural rubber 50 Shore or white silicone 35

Shore.

Multi-stage Vacuum Pumps General Characteristics

Supply: non-lubricated air, filtered to 5 microns, according to standard

ISO 8573-1:2010 [3:4:4]

Operating pressure: from 2 to 8 bar

Optimal dynamic pressure:

- CMSHDE_NVO (for CVGL_G0N_ grippers) without control: 5.5 bar.

- CMSHDE_S_/ CMSHDE_V_ with control (for CVGL_S/CVGL_V_ grip-

pers): 6 bar.

Pressure connection: G3/8”-F with removable 350 μm filter screen

Max. vacuum: 80%

Air suction flow rate: 700 to 2200 Nl/min

Air consumption: 220 to 840 Nl/min

Noise level: – CMSHDE90X50__K: 59 dBA

– CMSHDE90X100__K: 62 dBA

Degree of protection: IP65

Max. operating frequency: 4 Hz

Endurance: 50 million cycles

Materials: PA GF, brass, aluminum, steel, NBR, PU, FKM

M12 and M8 male connectors (depending on version)

Integrated electronics

24 V DC power supply (regulated ±10%)

Inputs/outputs protected against reversed wiring and polarity

Consumption: 170 mA max. (without load)

Only on models CMSHDE___VX__ installed on CVGL __S2 / V2:

Vacuum measuring range: 0 to 99%

Pressure measuring range: 0 to 10 bar

Vacuum and pressure measurement accuracy: ±1.5% of the range,

compensated for temperature

Input/Output switching mode: PNP or PNP/NPN configurable

Digital inputs/outputs mode (SIO) / IO-Link

DO1 output signal

Only on models CMSHDE___VX__ installed on CVGL __S2 / V2:

Configurable as PNP or NPN

NO or NC

Breaking capacity: 330 mA

DO1: object gripped output (factory setting 40%)

Diagnostic

Only on models CMSHDE___VX__ installed on CVGL __S2 / V2:

Instantaneous vacuum level (unit transmitted over IO-Link: mbar)

Available information: Object gripped, object lost

Cycle counters (vacuum, blow-off, object gripped, object lost, etc.)

Supply pressure monitoring

Supply voltage monitoring

Product part number and serial number

Software version

Indicator on models CMSHDE__VOC15P__ installed on CVGL __S1 / V1:

Status LED for control functions:

- Green LED: vacuum control

- Orange LED: blow-off control

Information displayed on HMI (VI option)

LED gripping status indicator on front panel (Green: object gripped,

Red: object lost)

1.54” high-visibility color LCD display:

- Displays vacuum level with bar graph and thresholds

- Warns when service life has been exceeded (> 50 million cycles)

- Explicit fault messages

- “Suction cup” icon indicating the status of control functions:

•Green suction cup: vacuum control

•Orange suction cup: blow-off control

•Red suction cup: simultaneous vacuum and blow-off control

- Configurable display orientation: 0 - 90 - 180 - 270°

Parameter settings available with the HMI or IO-Link

Only on models CMSHDE___VX__ installed on CVGL __S2 / V2:

Choice of blow-off type:

- Controlled

- Automatic timed, adjustable from 50 to 9999 ms

Object gripped (L1) control thresholds

Whenever required by the application, specific threshold and hystere-

sis settings that are different from the initial factory settings can be

defined: L1 = 40%, h1 = 10%

Additional settings available only with the HMI

(performed with 4-key membrane keyboard):

Choice of language: EN, FR, DE, IT, or ES

Choice of vacuum measurement unit (kPa, %, mbar, inHg)

Choice of pressure measurement unit (MPa, bar, psi)

Monostable electrical manual controls

Communication

IO-Link

Revision: 1.1

Transmission rate: COM3 - 230.4 kbit/s

Min. cycle time: 1 ms

SIO mode: Yes

Process Data Input (PDI): 6 bytes

Process Data Output (PDO): 1 byte

IO device description file (IODD) available for download

NFC

COVAL VACUUM MANAGER mobile app available:

- Android, version 8.1 and higher

- iOS, version 13 and higher

8. CHARACTERISTICS

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-14-

www.coval.com

9. INSTALLING THE VACUUM GRIPPER

COMPRESSED AIR OR VACUUM NETWORKS:

Wear safety goggles

Make sure all ttings and tubes are tightened securely

Air line ends must be fastened to avoid any risk of being pulled off in the event of accidental breakage

9.1. Pneumatic Supply for Vacuum Grippers Equipped with One or More CMS HDE Vacuum Generators

(CVGL Version D1, D2, and D3)

Note: For CVGL vacuum gripper without vacuum generator (version G0), see section 9.2.3 "Connecting an external vacuum source”.

Pneumatic supply characteristics

Non-lubricated air, ltered to 5 microns, according to standard ISO 8573-1:2010 [3:4:4].

Operating pressure: from 2 to 8 bar.

Optimal dynamic pressure:

- CMSHDE_NVO (without control) for CVGL_G0N_ grippers: 5.5 bar.

- CMSHDE_S_/ CMSHDE_V_ (with control) for CVGL_S/CVGL_V_ grippers: 6 bar.

1 power supply for D1 and D2 generators (pressure connection: G3/8”-F with removable 350 μm lter screen).

2 power supplies for D3 generators (pressure connection: G3/8”-F with removable 350 μm lter screen).

Technical data of the integrated CMS HDE series vacuum generators

Vacuum generators Version Consumption

(Nl/min) / (SCFM)

Flow rate

(Nl/min) / (SCFM)

Max. vacuum

(%)

Sound level

(dBA)

CMSHDE_50_CVGL _ _ _D1 220 / 7.77 700 / 24.72 80 59

CMSHDE_100_CVGL _ _ _D2 420 / 14.83 1100 / 38.85 80 62

2 x CMSHDE_100_CVGL _ _ _D3 840 / 29.66 2200 / 77.69 80 65

Vacuum generators Version Min. internal line dia.

CMSHDE_50_CVGL _ _ _D1 Ø6 mm – max. length 2 m

Ø8 mm – max. length 6 m

CMSHDE_100_CVGL _ _ _D2 Ø6 mm – max. length 2 m

Ø8 mm – max. length 6 m

2 x CMSHDE_100_CVGL _ _ _D3 Ø8 mm – max. length 6 m

Lengths and diameters of compressed air supply lines

Flexible lines must be as short as possible in order

to minimize response times.

Make sure there is no pollution in the device

connections and lines.

Flexible lines must be connected without bends

and without crushing them.

9.2. Pneumatic Connection

NOTE: MODULE PROTECTION

Removable 100μm lter screen integrated in the vacuum connection to protect the pump against particles.

Possible additional lter on vacuum circuit: In the rare cases of ne dust in a wet environment, the use of an appropriate lter will

prevent any internal clogging: See COVAL catalog: “Filters for vacuum circuits”

IF THESE CONDITIONS ARE NOT OBSERVED, YOU RISK THE FOLLOWING ISSUES:

If the chosen internal diameter on the compressed air inlet is too small, the compressed air supply will be insucient to

achieve optimal performance. The generator will be unable to achieve the specied maximum vacuum rate.

If the chosen internal diameter on the vacuum inlet is too small, the airow is slowed down due to this restriction, which has

a negative effect on suction power and on suction or exhaust time.

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-15-

www.coval.com

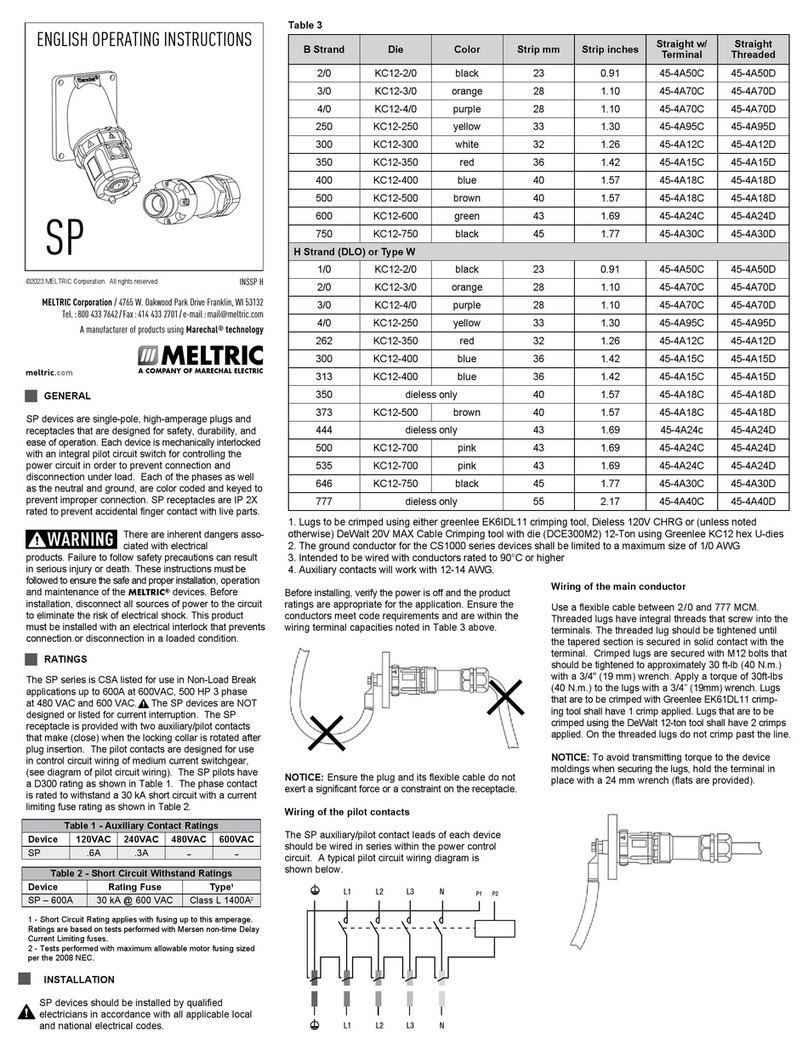

9.2.1. CVGL Versions D1 and D2

Connect the compressed air to the G3/8" connection on the CMS HDE series multi-stage vacuum generator.

Permissible tightening torque:

G3/8" pressure connection: 10 N m

G3/8"-F G3/8"-F

Version CVGL_N:

Without vacuum generator control

Version CVGL_Sor V :

With vacuum generator control

G3/8"-F

G3/8"-F

Version CVGL_N :

Without vacuum generator control

9.2.2. CVGL Version D3

Connect the compressed air to the two G3/8” ttings located on the CMS HDE series multi-stage vacuum generators.

Permissible tightening torques:

2 x G3/8" pressure connection: 10 N m

9.2.3. CVGL Version G0

Connecting an external vacuum source

To allow for an external vacuum source to be connected, version G0 of the CVGL vacuum gripper is equipped with a G1”-F threaded ange.

Permissible tightening torque:

G1" vacuum connection: 25 N m

Note: Diameter of supply lines must be suitable for the ow rate of the external vacuum generator.

G1"-F

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-16-

www.coval.com

1

2

4

3

51

2

4

3

5

124 3

50

9.3. Connecting a Vacuum Switch

In order for an external vacuum switch to be connected, the CVGL vacuum gripper is equipped with a

G1/8''-F connection.

Permissible tightening torque: vacuum switch connection G1/8"-F: 12 N m

NO

Model CVGL__S_: vacuum pump with NC

vacuum control and NC blow-off control.

In the event of power failure, vacuum is

no longer generated. In the event of com-

pressed air failure, the vacuum is no longer

maintained.

NC blow-off and vacuum control: solenoid

valves

Choice of blow-off settings

(only on CVGL__S2_ models):

- controlled by external signal

- automatic timer from 50 to 9999 ms

(advantage: saves one controller output)

Model CVGL__V_: vacuum pump with NO

vacuum control and NC blow-off control.

In the event of power failure, vacuum is still

generated: object is held in place

fail-safe.

In the event of compressed air failure,

the vacuum is no longer maintained.

NO vacuum control solenoid valve

NC blow-off control solenoid valve

Blow-off controlled by external signal

NC

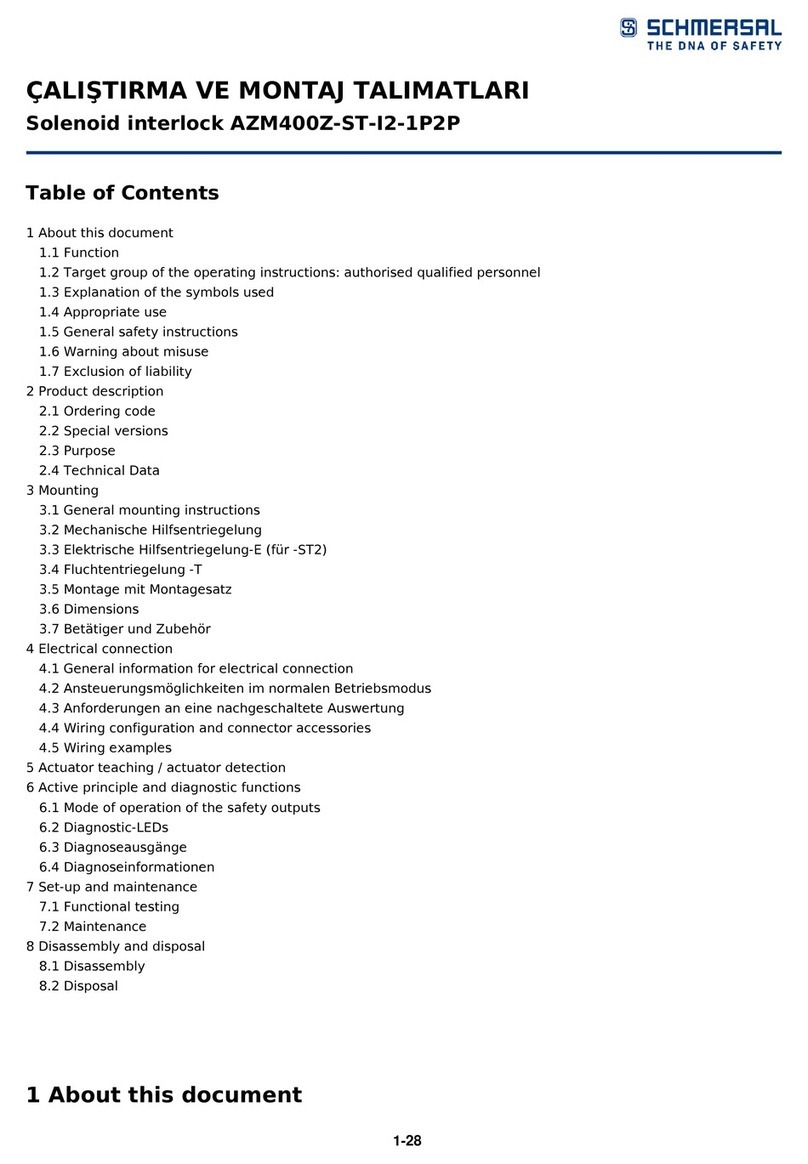

9.4. Electrical Connections: CVGL with Vacuum Generator Control (versions S and V)

When required, CVGL series vacuum grippers with integrated vacuum generator (versions D1 and

D2) can be equipped with a vacuum and/or blow-off control valve to optimize the release of gripped

objects. This also enables cleaning of the vacuum network, ow control nozzles, check valves, and

airtight valves. A vacuum switch or analog gauge is available as an option should a visual display of

the vacuum level in the system be needed (see below).

VACUUM CONTROL: 2 SOLUTIONS

ELECTRICAL CONNECTIONS

CMS HDE vacuum pumps must be used with power supply units that provide Protective Extra Low Voltage

(PELV) and supply voltage isolation according to EN 60204.

1/

224V DC suction command (1)

30V - GND

424V DC blow-off command

5/

124V DC

224V DC suction command (1)

30V - GND

424V DC object gripped DO1 - C/Q

524V DC blow-off command

CVGL _ S1 / V1:

One M12 5-pin male connector

CVGL _ S2 / V2:

One M12 5-pin male connector

124V DC

2RS485 (DATA+)

30V - GND

4RS485 (DATA-)

One M8 4-pin male connector HMI

: connections for

(1)

24V DC suction command, depending on version:

- S: 24V DC vacuum control

- V: 24V DC vacuum off command

vacuum switch

connection G1/8"-F

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-17-

www.coval.com

30

0

42 =22=

M3x6

25

85

=50=

120 10

14

40

2.0630

38

30

50

9.5. CVGL with Vacuum Level Display (Versions VA and VF)

When required, CVGL series grippers can include a vacuum level display with an electronic vacuum switch or vacuum gauge:

Option VA - electronic vacuum switch with 3-color display (PSD100CPNP): CVGL _ _ _ _ _ X _ _ VA

- Pressure rating range: 0 ~ -101.3 kPa.

- Pressure setting range: 10 ~ -101.3 kPa.

- Max. pressure: 300 kPa.

- Fluid: Air, non-corrosive/non-ammable gas.

- Hysteresis: adjustable.

- Response time: ≤ 2.5ms, with anti-vibration function.

- 7 segment LCD display: 2 color (red/green) main display, orange sub-display (refresh rate: 5 times/sec).

- Choice of pressure unit display: kPa, MPa, kgf/cm2, bar, psi, inHg, mmHg.

- Power supply voltage: 12 to 24V DC ±10%.

- Current consumption: ≤ 40 mA (without load).

- Repeatability (switch ouptut): ≤ ±0.2% F.S. ±1 digit.

- Electrical connection: M8 (4-pin).

- Protection: IP40.

- Ambient temperature range (operation): 0-50° C (32-106° F).

- Material (enclosure): PA 6.6 20%GF.

Option VF - vacuum gauge (VAF11140): CVGL _ _ _ _ _ X _ _ VF

- Vacuum gauge with needle.

- Damping: by silicone movement (patented).

- Measuring: Bourdon tube in CuSn.

- Precision: +/- 2.5% of max. scale value.

- Frame: black ABS

M8 straight female 4-pin

connector cable

0.3m length

Note: all dimensions are in mm.

10. INSTALLING AND OPERATING REMOTE HMI (CVGL VERSION VI)

Part number: Option VI: integrated on the vacuum gripper:

Option HMIHD1M84P: remote

Accessory only compatible with vacuum grippers CVGL__S2/V2_.

The CVGL__S2/V2_ vacuum grippers are supplied with the standard factory settings described in this manual.

To be able to modify them, you must use a remote HMI or congure the module using IO-Link..

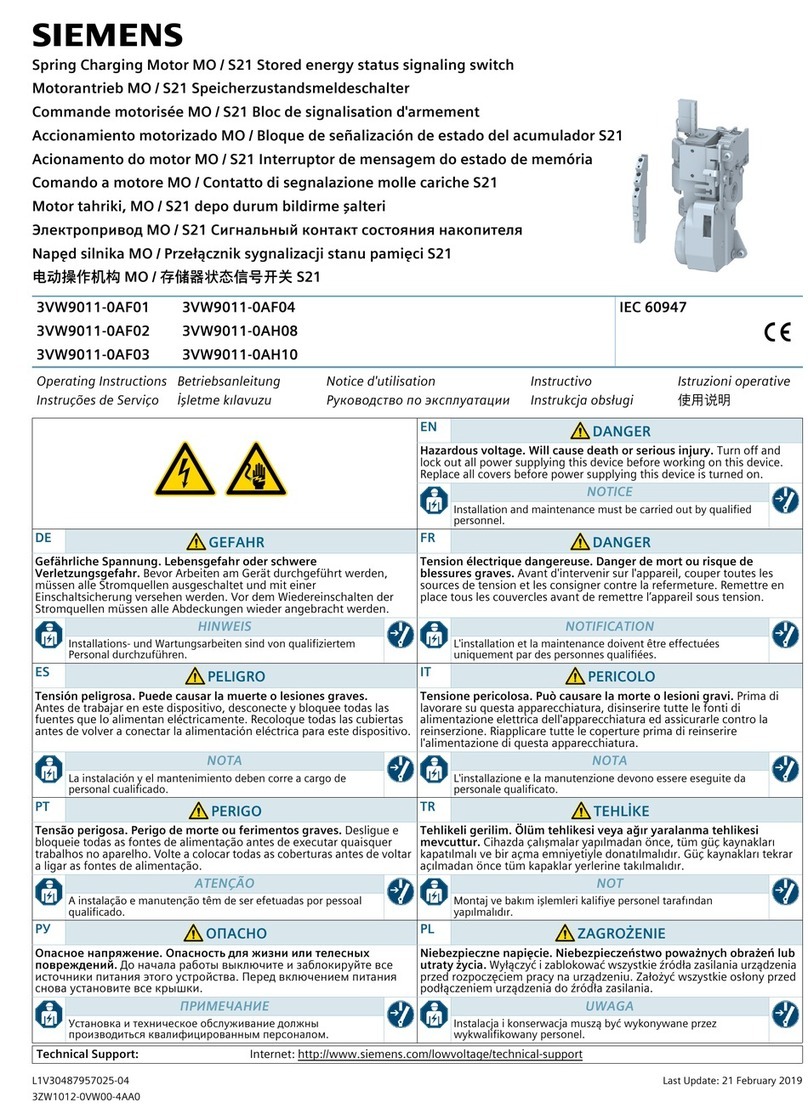

10.1. Dimensions

Option: CVGL____VI Remote HMI version: HMIHD1M84P

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-18-

www.coval.com

CMSHDE___VX__

YES

NO

Transfer and

apply settings

from HMI

module ?

YES/NO

10.2. Installing the Remote HMI, part no. HMIHD1M84P

HMIHD1M84P

M8 straight female

4-pin connector cable

0.3m lengthConnecting cable

One M8 male 4-pin connector

to connect remote HMI Connect the HMI’s M8 female 4-pin

connector to the M8 male connector on

the pump’s valve block (marked ).

If necessary, use a M8 female 4-pin / M8

male 4-pin connecting cable, compatible

with drag chain:

Length 2m:

- Part no. CDM8MF4PL2

Length 5m:

- Part no. CDM8MF4PL5

Process settings (for details see sect. 14)

L1/h1

Automatic blow-off

Device settings (for details see sect. 16)

PNP/NPN

NO/NC

10.3. Conguring a Remote HMI

Reminder: The remote HMI (part no. HMIHD1M84P) can only be used

withvacuumgrippersCVGL_S2/V2 (equippedwithCMSHDE___VX__

multi-stage vacuum pumps).

The CMSHDE___VX__ multi-stage vacuum pumps are supplied

with the standard factory settings described in this manual. To be

able to modify them, you must use a remote HMI or congure the

module using IO-Link.

Conguration procedure

Step 1: Connect the remote HMI to M8 connector (marked ) on

the CMSHDE. The CMSHDE must be powered on.

Step 2: When the HMI is powered on, a message is displayed asking

which settings should be used (HMI or IO).

Transfer and apply settings from the HMI module? YES/NO?

Step 3: Choose either YES or NO.

NO (selected by default): If the user presses M or does nothing within 5seconds, the settings present in the vacuum switch of the

CMSHDE are transferred to the remote HMI.

YES: The process settings and device settings contained in the remote HMI are transferred to the vacuum switch of the CMSHDE and

applied immediately.

This operation can be used to copy settings from one product to the next. The device’s own product ID, serial number and device name

remain unchanged. Likewise, the display settings (language, vacuum and pressure units, display rotation), also called “user settings”, are

not transferred since they are only related to the remote HMI.

Reminder:

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-19-

www.coval.com

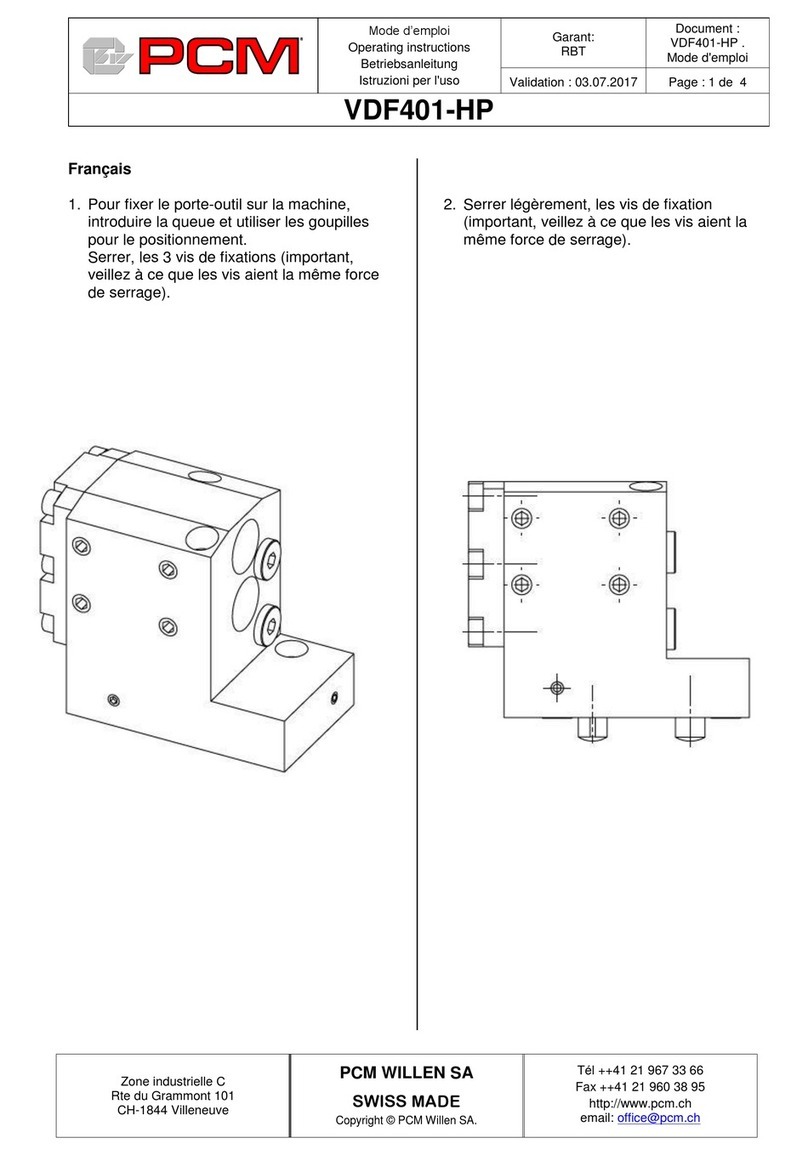

%

➊

➑

➌

➍

➏

➋

➎

➐

%

➊ Gripping status indicator light:

Green: object gripped

Red: object lost

➋ Status indicator for vacuum and blow-off control:

Vacuum generation

Blow-off

Simultaneous vacuum and blow-off control

➌ Instantaneous vacuum level (in kPa, % vacuum, mbar, or inHg)

➍ Bar chart indicating the instantaneous vacuum level

➎ L1 vacuum threshold: threshold for “object gripped” signal

➏ Keypad: Mbutton (menu), and buttons button (return)

➐ NFC antenna

➑ Maintenance indicator

10.4. Front Panel Dialog

The HMI allows for easy and ecient reading of the pump's operation.

The 1.54” high-visibility color LCD screen gives real-time access to the process

data, settings, and diagnostic data.

Status indicator for vacuum and blow-off

commands:

-: Vacuum generation

-: Blow-off command

-: Simultaneous vacuum and blow-off

commands

Maintenance indicator

Icon shown if the vacuum solenoid valve has

reached 50million cycles.

Instantaneous vacuum level

Displayed in:

- kPa: 0 to -99

- Vacuum %: 0 to 99

- mbar: 0 to -999

- inHg: 0 to -29.9

L1 vacuum threshold

L1: Threshold for “object gripped” signal

Vacuum unit

kPa / % of vacuum / mbar / inHg

Variable message

Displays code + error messages, alarms

(see sect. 18) Bar chart indicating

the instantaneous vacuum level

11. HMI DETAILS AND FEATURES

11.1. Powering On

The following occurs when the device is powered on:

- 1: COVAL logo is displayed (for about 15seconds).

- 2: Main screen is displayed showing the vacuum level.

- 3: The keypad is locked by default.

Note: During the startup phase (1), the product is immediately operational in terms of inputs/outputs (suction/blow-off commands,

contact outputs). Only the “HMI” part is being initialized during this phase.

11.2. Details of the Main Screen

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

-20-

www.coval.com

80

kPa

46 Nl/min

Input/Output mode

SIO

Mpa

Inlet pressure

Air consumption

0.1259

Live Data (1/2)

V

1024773

Blow off cycles

Power supply voltage

20.5

Vacuum cycles

1012927

Live Data (2/2)

From main screen: access main menu

Validate menus and settings

From main screen: access secondary screen

From menus: return to previous menu

Navigate to screens and menus

Increase/decrease values

Hold down to quickly scroll through values

11.3. Keypad Functions

The keypad consists of 4 keys used to navigate to the various menus/screens and to change the parameters, etc.

Lock/unlock keypad

Secondary screens: live diagnostic data

Shows operating mode of device (automatic detection) and communication status (if IO-Link):

- SIO: standard input/output mode.

- IO-Link: IO-Link mode and communication established.

Instantaneous supply pressure monitoring

(bar, MPa, psi depending on unit dened in dedicated menu)

Value is shown in orange if it is outside the authorized range. Otherwise, it is shown in green.

Instantaneous air consumption in Nl/min

Power supply monitoring

Value is shown in orange if it is outside the authorized range. Otherwise, it is shown in green.

Vacuum and blow-off cycles

Main screen

12. SUMMARY OF FUNCTIONS

12.1. Accessing Live Diagnostic Data

EN

CVGL series

Vacuum Grippers OPERATING INSTRUCTIONS

Table of contents

Other coval Industrial Equipment manuals