OPERATING MANUAL DAB530 SAFETY

Warranty and liability

As a general principle, the "General Terms of Sale and Delivery" of

THYSSENKRUPP AUFZUGSWERKE GmbH apply

Warranty and liability claims in the event of personal injury and damage to

property shall be excluded if they arise due to any of the following causes:

•Improper use that is not in line with the intended purpose of the DAB530

•Installation, commissioning, operation and maintenance of the DAB530

that is not in line with accepted technical principles

•Operation of the DAB530 with defective and/or

Non-operative safety and protection devices

•Nonobservance of the instructions in the operating manual with regard to

Transportation, storage, installation, commissioning, operation and

servicing of the DAB530

•Constructional changes to the DAB530 performed by the operator

•Changes to the drive ratios / power output etc. performed by the operator

•Deficient monitoring of parts that are subject to

wear

•repairs that are carried out improperly

•cases of catastrophe due to third-party interference and force majeure.

Constructional changes to the DAB530 performed by the operator

The parts installed in and attached to the DAB530 are mounted and set at

the plant.

If changes are made to the machine, this renders null and void the entire

warranty of ThyssenKrupp Aufzugswerke GmbH

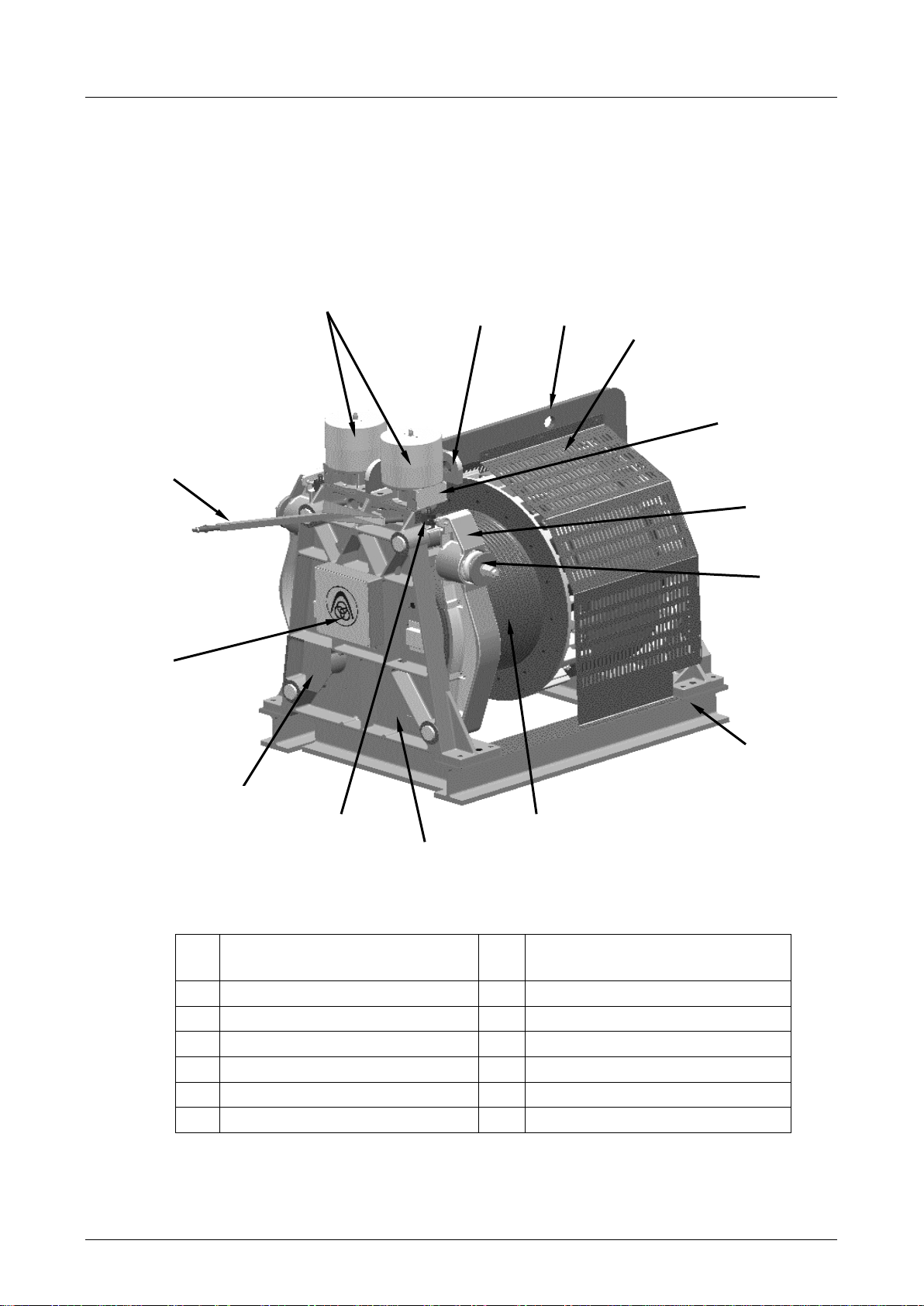

Dangers in handling the DAB530

The DAB530 may only be operated in an enclosed machine room and only

with the screen fitted.

Before mounting the manual drive, the power to the drive must be

disconnected and the installation secured against inadvertent activation.

Remove the manual drive before reconnection and screw on the cover plate.

It must be ensured when persons are in the machine room that there is

adequate safety clearance to all revolving (marked in yellow) parts.

In the event of improper use, there is a risk of personal injury or to the life of

the user or third parties, or impairment on the assembly or other assets can

arise.

Malfunctions that can impair safety must be rectified immediately.

ThyssenKrupp Aufzugswerke GmbH